Warning, Maintenance and service – AMMCO 7700 Drum and Disc Brake lathe User Manual

Page 18

14 • AMMCO Drum & Disc Brake Lathes

Maintenance and Service

Before making any inspection, adjustment,

or repair, make sure lathe is turned OFF and

disconnect the power source.

Wear protective clothing, equipment and

eye protection when making any adjust-

ments or repairs to the machine.

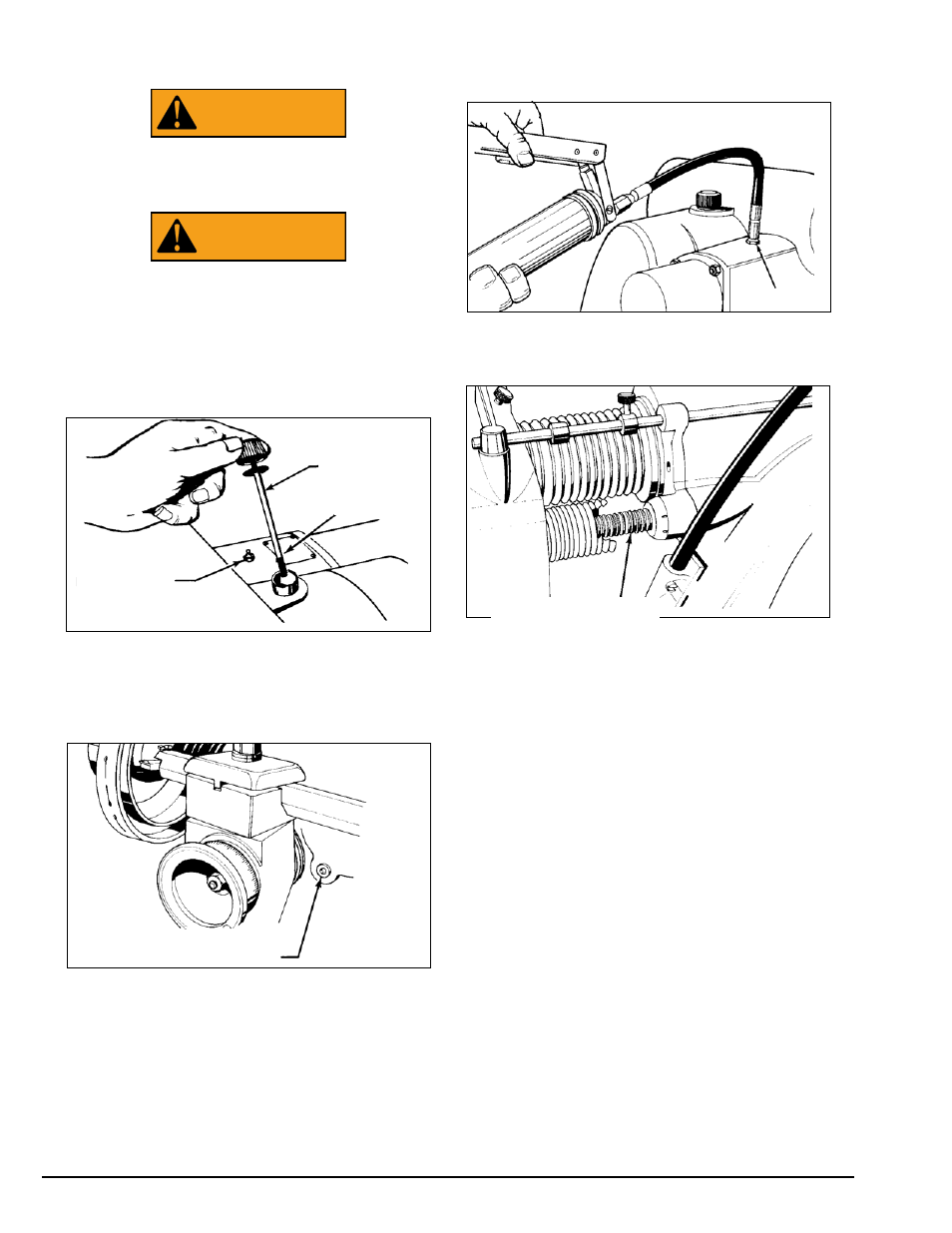

Oiling

The lathe is shipped from the factory with the correct

amount and type of oil. Check oil level frequently, and

refill as necessary with EP-80-90 gear oil.

Figure 34 – Oiling

After every 500 hours of use, drain the oil and refill to

the appropriate level on the dipstick with clean EP-80-

90 gear oil. Use the oil drain plug on the front of the

lathe to drain the old oil.

Figure 35 – Drain plug location

The Infimatic

®

Variable Feed Gearbox and the disc

brake feed mechanism assemblies are filled with a spe-

cial lubricant and need no further internal lubrication.

Lubricate the cross feed once each month with an

automotive chassis grease. Pump the grease into the

fitting until clean grease comes out the relief slot at the

base of the fitting.

Use a hand pump grease gun only. A high pressure

gun can burst the lathe casting.

Figure 36 – Cross feed grease fitting

Grease the lead screw drive monthly. Locate the lead screw

drive by pulling the protective boot back.

Figure 37 – Lead screw drive

Oil exposed metal parts periodically to prevent rust.

WARNING

WARNING

Grease fitting

for cross feed

Dipstick

Oil level

Oil drain plug

Relief slot

Feed mechanism lead screw