AMMCO 7700 Drum and Disc Brake lathe User Manual

Page 13

AMMCO Drum & Disc Brake Lathes • 9

J

A

D

E

G

C

B

A H

F

E

G

C

B

F

A

J

I

A

K

C

B

J

A

A

B

C

G

F

H

E

I

C

B

E

F H

F

B

C

G

E

A

H

G

C

B

A

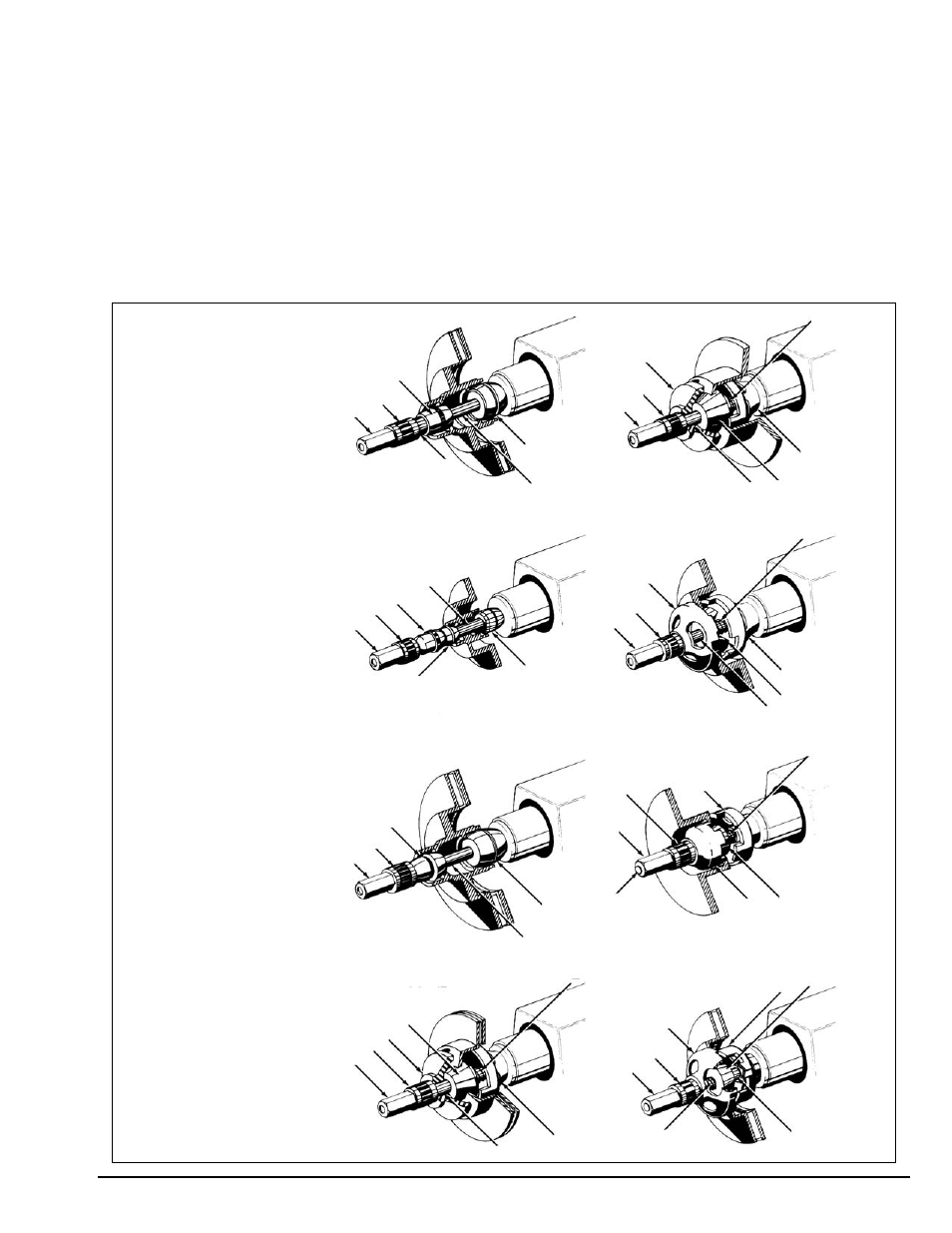

A - 1” Arbor

B - Arbor Nut

C - Self-Aligning Spacer

D - Spacer

E - Spring

F - Small Hubless Adapter

G - Large Hubless Adapter

H - Centering Cone

I - Small Double Taper Adapter

J - Large Double Taper Adapter

K - Adapter, Used as Spacer

Rotor Mounting

Review the descriptions of mounting a brake drum on

page 6. The same directions apply when mounting a

brake rotor. Hubbed rotors are mounted on adapters

that fit into the bearing races. Hubless rotors use a

cone in the center hole and a hubless adapter on each

side of the rotor. Spacers are used to fill out the arbor

shaft so that the arbor nut can be tightened. The

setups illustrated in Figure 20 are typical of the many

mounting configurations necessary to meet the

requirements of brake rotor reconditioning. The

adapters, cones, and spacers supplied with the lathe

will allow reconditioning of the majority of the rotors

found on current production vehicles. Optional

adapters, cones, and spacers are available to meet spe-

cial needs.

Note: Adapters may also be used as spacers to fill out

the arbor shaft if care is taken to prevent damage to

their machined surfaces.

The patented self-aligning spacer prevents diagonal

thrust on t he adapters. The self-aligning spacer should

always be used adjacent to the arbor nut.

C

I

B

H