Reconditioning disc brake rotors – AMMCO 7700 Drum and Disc Brake lathe User Manual

Page 12

8 • AMMCO Drum & Disc Brake Lathes

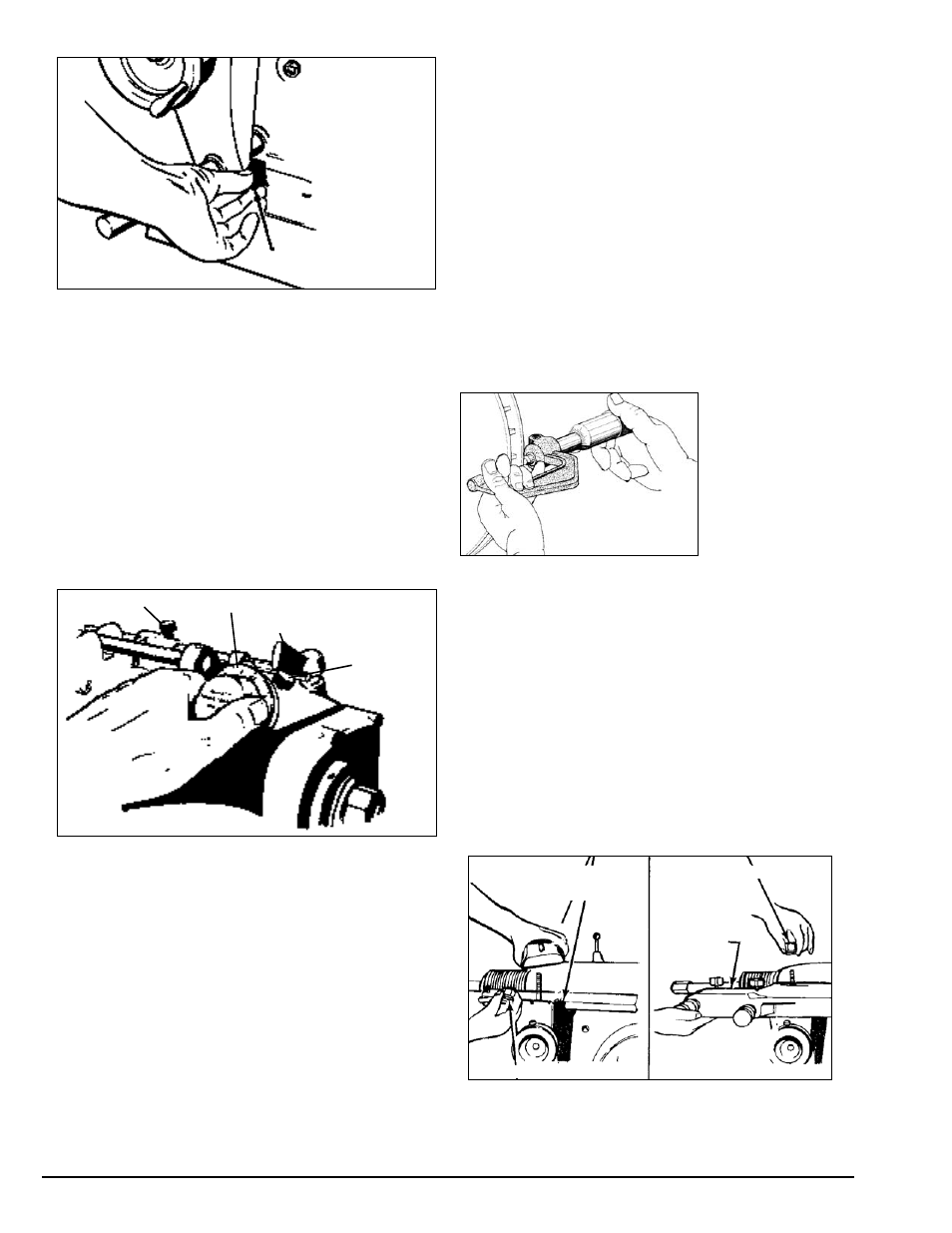

Figure 16 – Lock cross feed

20.

Set the spindle feed speed while the lathe is run-

ning by unlocking the feed dial lock screw and turning

the dial. Tighten the lock screw when speed is set.

The rough cut feed range is between 0.006” (0.15

mm) (6 on the dial) to 0.020” (0.50 mm) (20 on the

dial).

The finish cut feed range is between 0.002” (0.05

mm) (2 on the dial) and 0.006” (0.15 mm) (6 on the

dial).

21.

Set the feed shut-off by sliding it on the shaft to

a point that approximately equals the depth of the drum

and tightening it in place. The feed will stop when it

reaches this point.

Figure 17 – Set spindle feed shut-off

22.

Engage the feed lever to begin drum recondi-

tioning.

Reconditioning Disc Brake

Rotors

Preparation

1.

Inspect the rotor carefully for scoring, rust ridges

(at the inner and outer circumference of the rotor), and

hard spots. Any excessive wear or deformity should be

noted and, if not within acceptable limits, the rotor

should be replaced.

2.

Use a micrometer to check the thickness of the

rotor at no less than 3 points around the circumference

about 1” (2.54 mm) in from the outer diameter.

If the rotor thickness varies between readings, it

should be reconditioned. However, if the thickness is

less than the minimum established by the manufac-

turer, or if it will be less after reconditioning, the rotor

should be replaced.

Note: Most often

the DISCARD thick-

ness dimension is

cast or stamped

into the rotor, not

the minimum

machine-to thick-

ness.

Figure 18 – Measure rotor thickness

Twin Cutters

A twin cutter tool is used on the 4000, 4100, and

7500 to recondition both surfaces of a brake rotor at

the same time. The twin cutter replaces the boring bar

on top of the cross feed after removing the upper and

lower tool bar clamps.

Model 6950 Twin Cutter—4000 & 7500

1.

Mount the twin cutter on the cross feed with the

stud bolt extending through the cast slot. The slot

helps center the twin cutter to the rotor.

2.

Secure the twin cutter to the cross feed with self-

aligning nut and washer assembly. Tighten the nut

firmly.

Figure 19 – Install the twin cutter

Cross slide self-aligning nut/washer

Twin cutter

Cross slide self-aligning nut/washer

Upper and lower

boring bar clamps

Cross Feed Lock

Knob

Feed shut-off

Spindle feed lever

Spindle feed dial

Feed dial

lock screw