2 drive hub -rear (prior to s/n 0300112585), Disengaging for towing, Drive hub -rear (prior to s/n 0300112585) -2 – JLG M600 Service Manual User Manual

Page 40: Disengaging for towing -2, Wheel torque chart -2

SECTION 3 - CHASSIS & TURNTABLE

3-2

– JLG Lift –

3121813

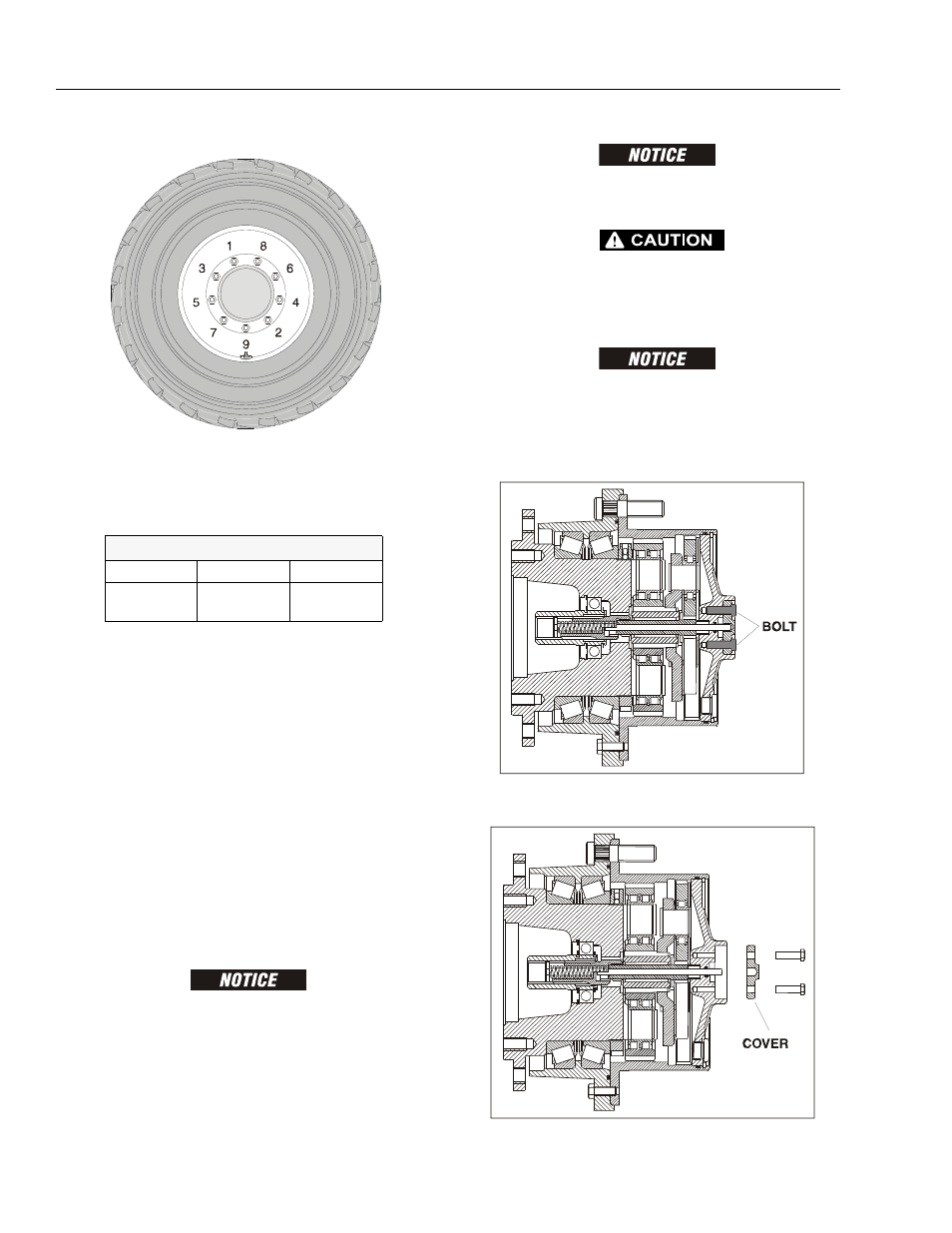

2. Tighten nuts in the following sequence:

3. The tightening of the nuts should be done in stages.

Following the recommended sequence, tighten nuts

per wheel torque chart.

4. Wheel nuts should be torqued after first 50 hours of

operation and after each wheel removal. Check

torque every 3 months or 150 hours of operation.

3.2 DRIVE HUB -REAR (PRIOR TO S/N

0300112585)

The final drive consists of two planetary stages with an

integrated disconnect mechanism. Each stage incorpo-

rates a set of matched planetary gears, which provide an

equal load distribution. All torque transmitting compo-

nents are made of forged quenched and tempered high-

alloy steels. External gears are carburized. Precision roller

bearings support the sprocket or wheel loads. A shaft seal

protects the unit against contamination.

Disengaging for Towing

PRIOR TO OPERATING THE DISCONNECT THE MACHINE HAS TO

BE ON LEVEL GROUND AND COMPLETELY SECURED FROM ANY

MOVEMENT, I.E. VIA TOW BAR TO PULLING VEHICLE. THE

MACHINE SHOULD NOT BE MOVED UNLESS IT IS SECURED TO

THE TOWING VEHICLE TO PREVENT RUNAWAY.

ENSURE THE DISCONNECT MECHANISM IS ONLY OPERATED

WITH THE MACHINE AT A STANDSTILL.

THE GEAR DRIVE TEMPERATURE SHOULD BE CHECKED PRIOR

TO ANY WORK BEING DONE. THIS IS IMPORTANT IF THE GEAR

DRIVE HAS RECENTLY BEEN OPERATED SINCE IT MAY BE HOT

AND CAUSE INJURY.

ENSURE THE AREA SURROUNDING THE DISCONNECT IS

CLEANED PRIOR TO OPERATION. ENSURE THAT DIRT OR OTHER

CONTAMINANTS DO NOT ENTER THE GEAR DRIVE.

1. Remove the two hex head bolts from the cover.

2. Remove the cover.

Table 3-1. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40 ft. lbs.

(55 Nm)

100 ft. lbs.

(130 Nm)

170 ft. lbs.

(255 Nm)