2 load cell calibration procedure, Load cell calibration procedure -8, Platform support torque values -8 – JLG M600 Service Manual User Manual

Page 118

SECTION 4 - BOOM & PLATFORM

4-8

– JLG Lift –

3121813

4.2 LOAD CELL CALIBRATION PROCEDURE

1. Place the machine in the stowed position.

2. Activate both emergency stop switches and turn the

key switch to the platform position.

3. Remove all loads from the basket including the

operator.

4. Turn P1 clockwise (in) until the potentiometer begins

to click.

5. Plug the analyzer into the port in the platform.

6. Enter the password 33271.

7. Select Machine Set-Up/Load Cell/ 1=Warn Only.

8. Select Diagnostics/System/Load Cell on the Ana-

lyzer.

9. Adjust P2 until the load = 0%.

10. Place 455 lbs. in the center of the basket.

11. Adjust P1 until the load = 100%.

12. Verify that the overload lamp lights continuously and

the alarm sounds continuously during an overload

condition.

13. Remove the weight from the basket.

14. Adjust P2 until the load = 0%.

15. Place 500 lbs. (230kg) in the center of the basket.

16. Adjust P1 until the load = 95%.

17. Add 55lbs. (25kg) in center of the basket.

18. Verify that the overload lamp lights continuously and

the alarm sounds continuously during an overload

condition.

19. Remove weight from the basket.

20. Seal Potentiometers with fingernail polish.

21. When an overload condition is reached, the

machine will give an indication by activating the tilt

alarm, lighting the overload light, put all platform

functions into creep, cutout lift up and telescope out

at platform and ground.

The horn will be activated when MTB ground control

switch is selected to ground and overload condition

is reached.

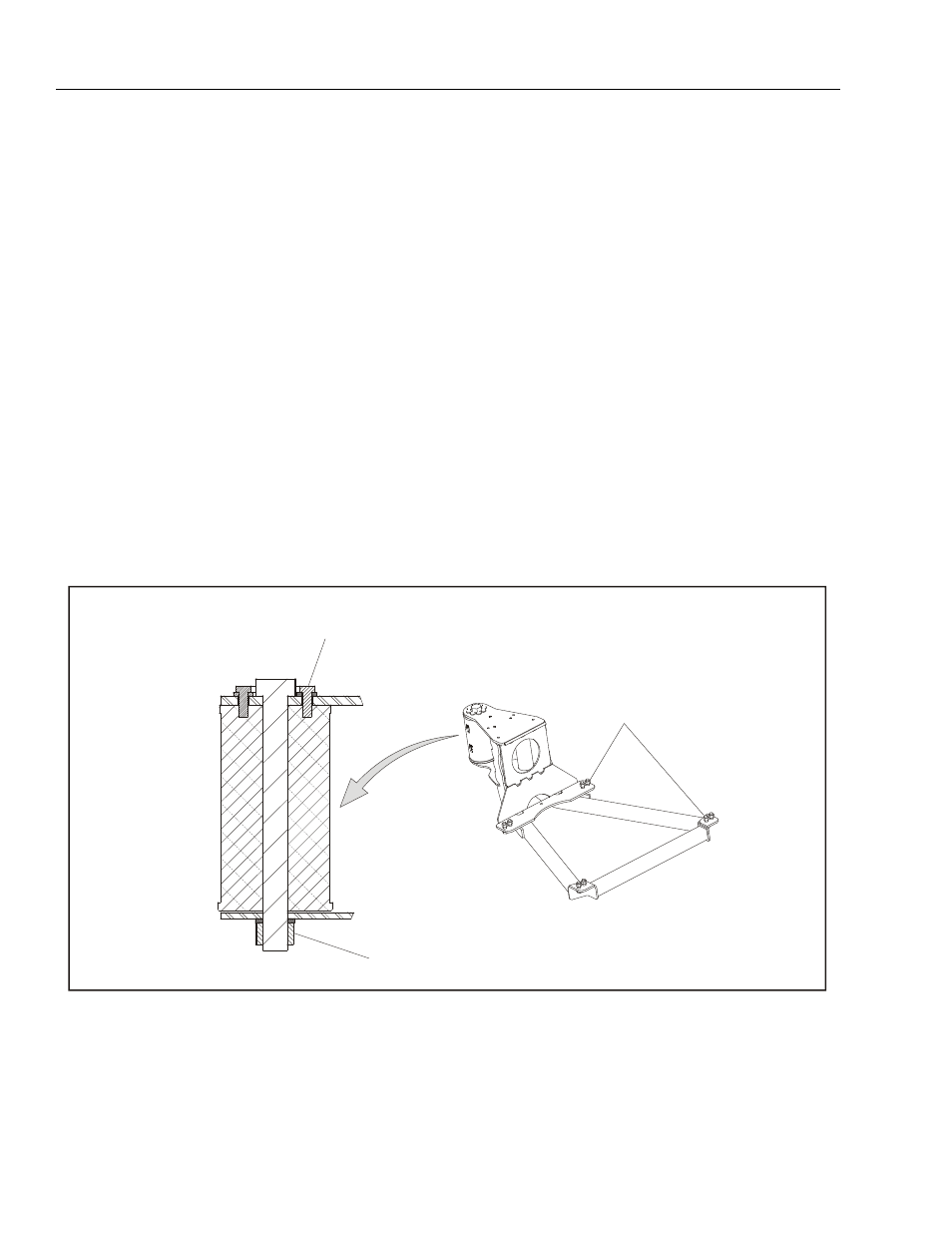

A,B,D

C,D

E

A

B

C

D

E

Torque to 50 ft.lbs. (68 Nm)

Loctite #242

Torque to 480 ft. lbs. (650 Nm)

Check torque every 150 hours of operation

Torque to 85 ft. lbs. (115 Nm)

Figure 4-6. Platform Support Torque Values

NOTE: If any rotator bolts are replaced, all bolts

on the rotator should be retorqued.