Understanding rated capacity charts, How to read a capacity chart – JLG TF6-42 (9150-4003) Operator Manual User Manual

Page 34

13.2

How to read a Capacity Chart

When reading the capacity chart you must check to be sure the correct model

number is listed (see figure 12-6). The next thing to look for is that the part

number of your attachment is listed under the “Use With” section.

Identify and find the amount of boom extension required, along with the

angle of the boom. Trace the boom extension arc down until it intersects

with the appropriate boom angle. If the intersection of the boom extension

arc and the boom angle line occur within a weight region, the value within

that region is the maximum capacity for that particular lift. If the intersection

occurs on a bold line separating capacity regions, the smaller of the two

values must be used. The regions are clearly marked with heavier outlines

as shown on page 12.4. If you do not have the correct capacity chart for

your machine and/or attachment, contact your Distributor or Gradall to order

one.

Example (this is for instructional purpose only - use capacity chart

located in your cab):

A contractor has purchased a TF6-42 with the 48” Slope Piler Carriage

Attachment (see figure 12-6). He knows his attachment may be used with

this model since the attachment part number, 9140-5101, matches the

attachment part number stamped on the machine Serial Number Plate. He

also knows that the Capacity Chart is correct since it is clearly marked for

use with a TF6-42 and that the attachment he is using is listed at the bottom

by part number. He has determined the weight of the load to be lifted is 400

lbs. and that he needs to place the load at a boom extension of 6 at a boom

angle of 20°. By tracing the boom extension arc down to where the 20° line

intersects it, the contractor can see that the maximum weight he can lift is

800 lbs. In this case, he may lift the load.

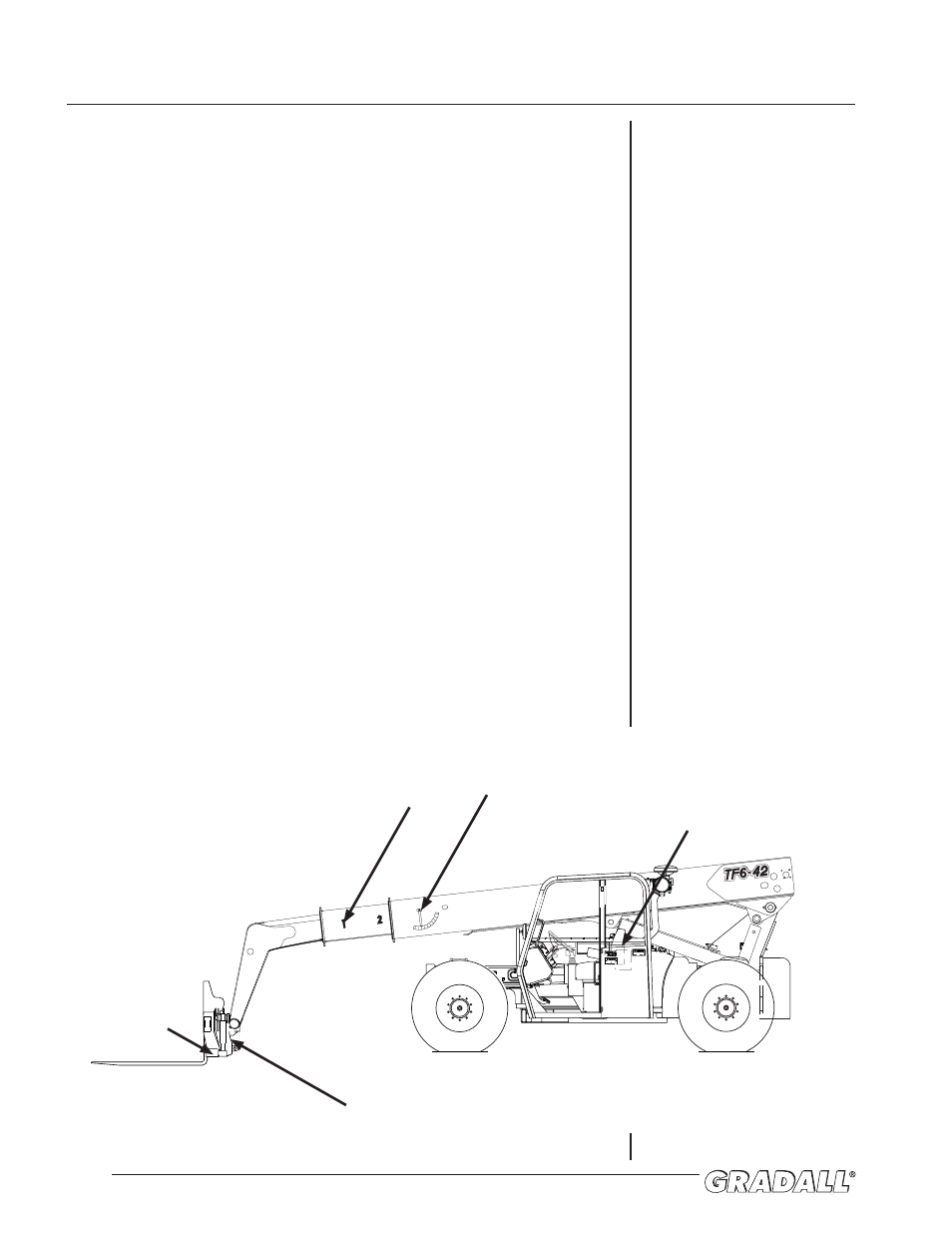

Figure 12-5:

Where to look on the machine

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

9114-3282

STAY CLEAR OF PINCH POINT AREA

ANYTIME ENGINE IS RUNNING.

BEING IN PINCH POINT AREA COULD

CAUSE SERIOUS INJURY OR DEATH.

DO NOT GO NEAR LEAKS

C

10814B

* High pressure oil easily punctures skin causing serious injury, gangrene or death.

* If injured, seek emergency medical help. Immediate surgery is required to remove oil.

* Do not use finger or skin to check for leaks.

* Lower load or relieve hydraulic pressure before loosening fittings.

9114-3283

NO RIDERS PERMITTED ON HANDLER.

OPERATOR ONLY IN MACHINE

WHILE RUNNING.

RIDERS COULD FALL OFF MACHINE

CAUSING SERIOUS INJURY OR DEATH.

9114-3286

DIESEL FUEL IS FLAMMABLE

EXTINGUISH ALL OPEN FLAME AND

SMOKING MATERIALS WHEN REFUELING

INJURY OR DEATH COULD RESULT

FROM FIRE.

** unknown **

** unknown **

** unknown **

** unknown **

2

NO

1

R

7733-3027

FORK WEIGHT

STAMP

BOOM

EXTENSION

NUMBER

BOOM ANGLE

INDICATOR

ATTACHMENT

IDENTIFICATION PLATE

MACHINE SERIAL

NUMBER PLATE

(RIGHT WALL)

UNDERSTANDING RATED CAPACITY CHARTS