Checking/adjusting armature plate gap setting, Brake assembly installation – JLG SSV10 Service Manual User Manual

Page 43

SECTION 3 - BASE COMPONENTS

3121187

– JLG Lift –

3-15

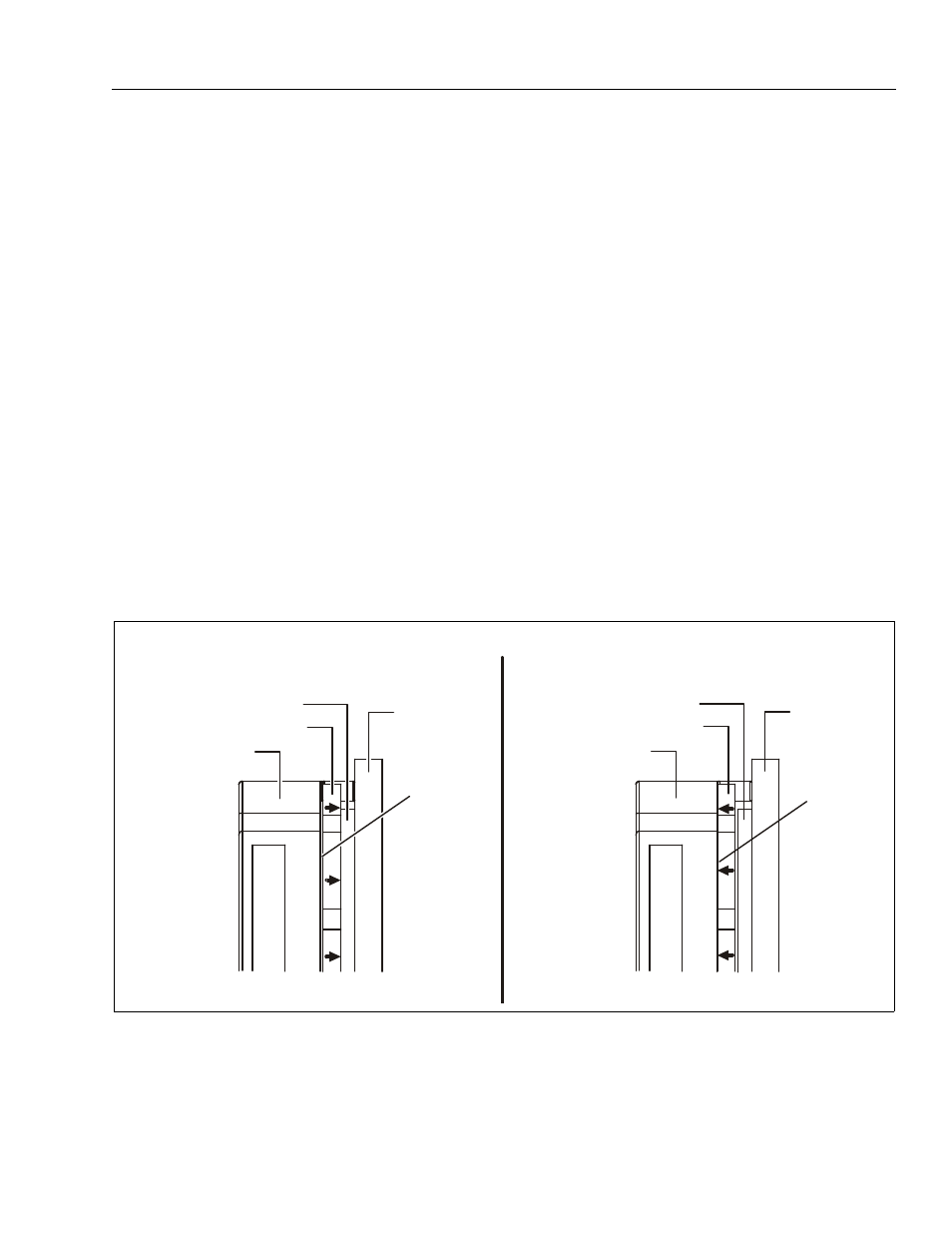

Checking/Adjusting Armature Plate Gap Setting

1. First inspect that all parts of the brake assembly are

tight and secure. Tighten as necessary.

2. Inspect the brake for any debris which may be

lodged in the air gap between the armature plate

and magnetic coil when the brakes are ENGAGED

(brakes on); on either side of the friction disk when

the brake is RELEASED (brakes off). Clean and

remove debris as necessary.

3. With the brakes ENGAGED measure the air gap

between the armature plate and the magnetic coil

housing. The correct setting should be .006", how-

ever the brakes will operate properly if the measure-

ment is a minimum of .004" and a maximum of .010".

(See "Gap Setting" Illustration this Section)

4. If the air gap falls outside the maximum allowable

setting of .010" the friction disk has worn. To correct

this replace the disk with a new one.

5. If the air gap is below the minimum allowable setting

of .004", recheck the areas between the magnetic

coil housing, armature plate, friction disk and

mounting plate for debris. Clean as necessary.

Brake Assembly Installation

1. Secure the brake assembly to the drive motor hous-

ing using four (4) hex cap screws with washers.

Torque evenly to 44 in. lbs.

2. Reinstall the protective rubber boot over the drive

motor housing, secure the boot with the boot clamp.

3. Reconnect the drive motor/brake power wiring con-

nector to wiring harness connector.

4. Install the drive motor cover.

Gap Setting - Brake Engaged

(magnet not energized-springs engage plate against disk)

1. Magnetic Coil

3. Brake Disk(Engaged) 5. .006" Gap

2. Armature Plate 4. Mounting Plate

Gap Setting - Brake Disengaged

(magnet energized-plate compresses springs, disk rotates freely)

1. Magnetic Coil

3. Brake Disk (Free) 5. Plate Engaged -

2. Armature Plate 4. Mounting Plate Springs Compressed

3

3

2

2

1

1

5

5

4

4