4 torque requirements, 5 lubrication, Hydraulic oil – JLG SSV10 Service Manual User Manual

Page 15: Lubrication specifications, 6 hydraulic pressure settings and adjustment, 4 torque requirements -3 1.5 lubrication -3, Hydraulic oil -3 lubrication specifications -3, 6 hydraulic pressure settings and adjustment -3, Hydraulic pressure adjustment screw -3, Hydraulic oil operating range -3

SECTION 1 - MACHINE SPECIFICATIONS

3121187

– JLG Lift –

1-3

1.4 TORQUE REQUIREMENTS

When maintenance becomes necessary or a fastener has

loosened, refer to the applicable Torque Chart (Figure 1-

4., Figure 1-5. and Figure 1-6.) in this section of the man-

ual to determine proper torque values for various size fas-

teners.

1.5 LUBRICATION

Hydraulic Oil

Hydraulic oils must have anti-wear qualities at least to API

Service Classification GL-3, and sufficient chemical stabil-

ity for mobile hydraulic system service. JLG Industries,

recommends Mobilfluid 424 hydraulic oil, which has an

SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures

remain consistently below +20°F (–7°C) JLG recom-

mends using Mobil DTE 13 hydraulic oil.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not con-

tain the same required additives or be of comparable vis-

cosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industries for proper recommenda-

tions.

Lubrication Specifications

1.6 HYDRAULIC PRESSURE SETTINGS AND

ADJUSTMENT

Adjust system pressure so that platform will raise with

maximum rated capacity in platform.

Perform pressure adjustment with oil at normal operating

temperature. If pressure is set when oil is cold, platform

may not raise rated load after oil has warmed.

The following pressure setting is the factory recom-

mended (initial) setting;

Turning adjustment screw clockwise increases system

pressure, turning screw counterclockwise decreases

system pressure. (See Figure 1-1., Hydraulic Pressure

Adjustment Screw. (Machine Front Cover Removed)

Table 1-3. Hydraulic Oil Operating Range

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

SAE VISCOSITY

GRADE

+0? F to +180? F

(-18? C to +83? C)

10W

+0? F to +210? F

(-18? C to +99? C)

10W-20, 10W-30

+50? F to +210? F

(+10? C to +99? C)

20W-20

Table 1-4. Lubrication Specifications

KEY

SPECIFICATIONS

MPG - Multipurpose Grease having a minimum dripping point

of 350° F. Excellent water resistance and adhesive qual-

ities, and being of extreme pressure type. (Timken OK

40 pounds minimum.)

EPGL - Extreme Pressure Gear Lube (oil) meeting API service

classification GL-5 or MIL-Spec MIL-L-2105.

HO - Hydraulic Oil. ISO-Vg grade 32, 46.

CL - Chain Lube. Use a good quality chain lubricant

MODEL

PRESSURE SETTING

SSV-10

1800 PSI

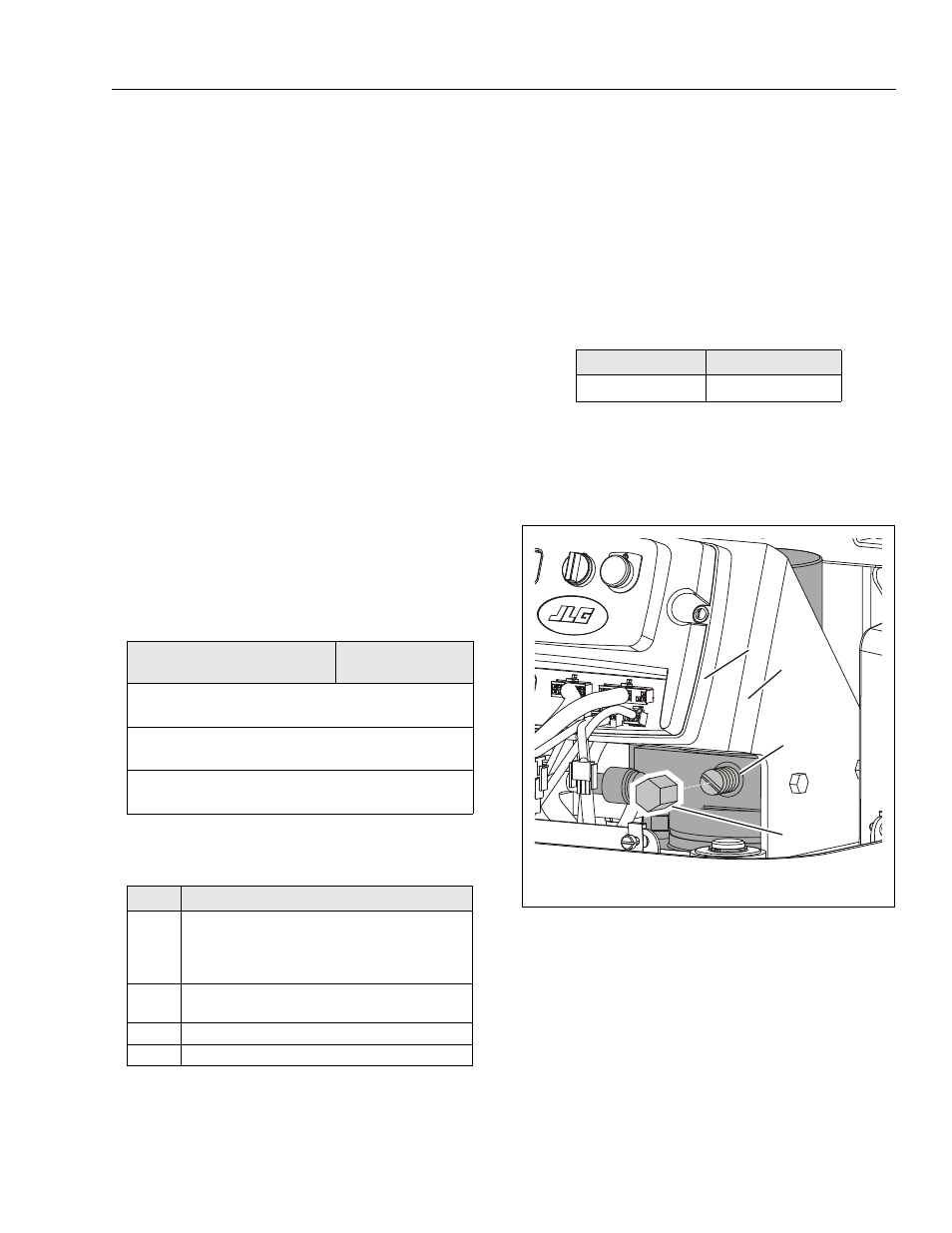

Figure 1-1. Hydraulic Pressure Adjustment Screw.

(Machine Front Cover Removed)

1. Pressure Adjustment Screw

2. Remove Adjust Screw Cap

3. Pump/Ground Station

Mounting Bracket

4. Ground Control Station

NOTE: Machine front cover must be removed to access

pump motor.

1

4

3

2