12 boom extend and retract chains, 1 boom chain inspection, Boom extend and retract chains – JLG G6-42A Service Manual User Manual

Page 65: Boom chain inspection, Warning

3-27

G6-42A, G9-43A, G10-43A

Boom

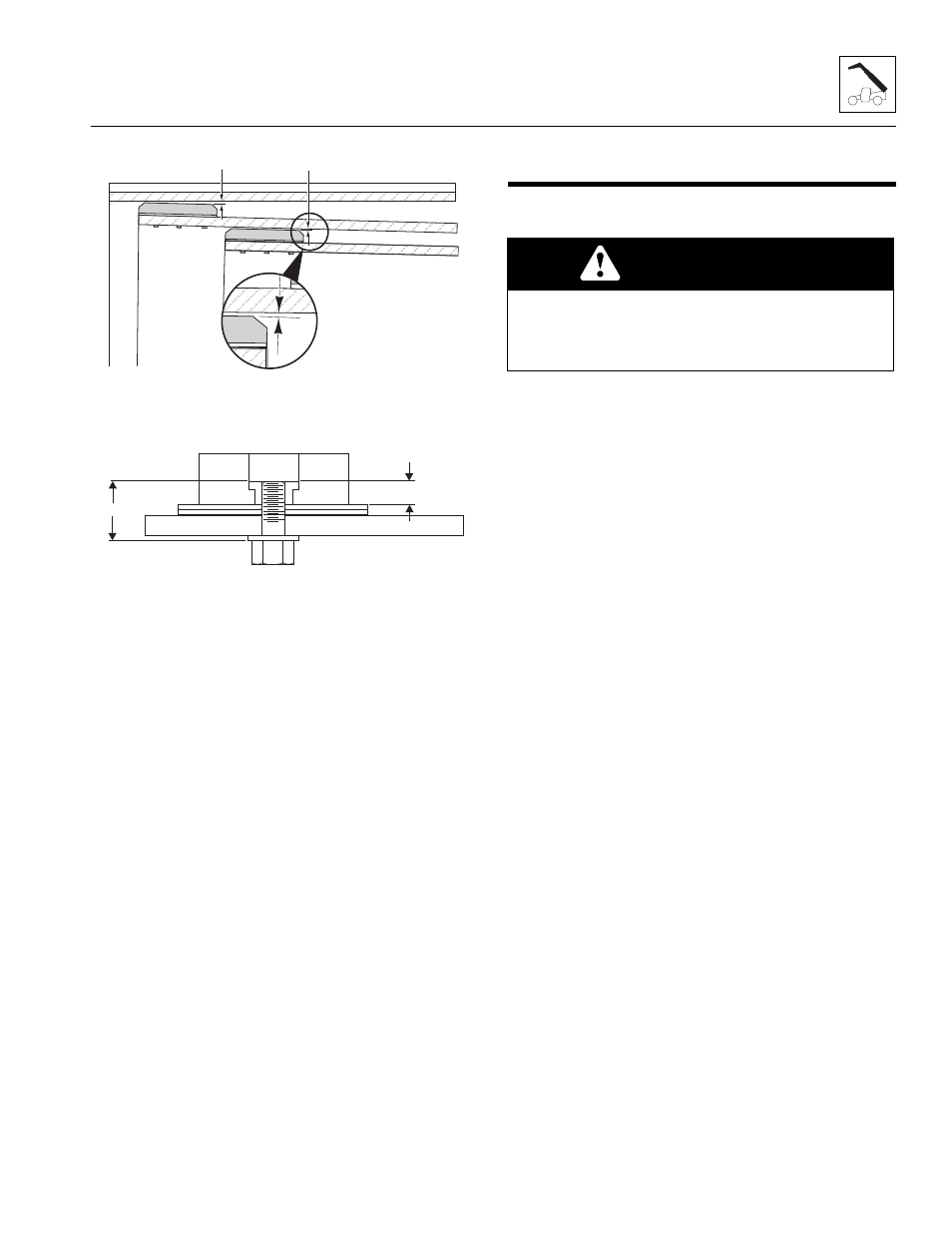

• Maintain a total boom section clearance (5) of

0.070 - 0.130 in (1,78 - 3,30 mm) both the horizontal

and vertical directions.

• The length of the wear pad bolt depends on the

number of shims, spacers and washers being used.

• The thickness of each threaded wear pad insert is

0.312 in (7,92 mm)(A).

• The bolt length should be determined by measuring

the distance from the face of the insert to the face of

the boom (B) including any spacer, shim(s) and

washer(s).

• Bolt thread engagement in the wear pad insert

should be 0.275 ± 0.040 in (6,98 ± 1,0 mm).

• One or two hardened washers are to be used on

each wear pad bolt except where noted otherwise.

DO NOT use more than two hardened washers.

• Use only one hardened washer if mounting bolts are

recessed.

• Wear Pad Bolt Torque:

3/8 - 24 Bolt, 32 - 37 lb-ft (43 - 50 Nm)

3/8 - 24 Hollow Bolt, 15 - 17 lb-ft (20 - 23 Nm)

1/2 - 20 Bolt, 76 - 86 lb-ft (103 - 116 Nm)

1/2 - 20 Hollow Bolt, 45 - 50 lb-ft (61 - 68 Nm)

• Torque wear pad bolts after shimming is completed.

• Lubricate the face and pockets of each wear pad

after being installed.

Boom Section Wear Pad Pathway Lubrication:

• Clean and lightly grease all wear pad pathways with

Mystik Tetrimoly grease.

Clean and lightly grease the hose carrier guide bar

pathways with Mystik Tetrimoly grease.

3.12

BOOM EXTEND AND RETRACT

CHAINS

3.12.1

Boom Chain Inspection

Under normal operating conditions the boom chains will

need to be inspected every

250

hours of operation. The

retract chains need to be exposed and inspected every

1000 hours of operation. Environmental conditions and

dynamic impulse/shock loads can drastically affect

normal operating conditions and require more frequent

inspection intervals.

Environments in which material handling vehicles

operate can vary widely from outdoor moisture to

temperature to mildly corrosive or highly corrosive

industrial atmospheres, in addition to abrasive

exposures such as sand and grit. Some effects can be

as follows:

• Moisture - Corrosive rusting reduces chain

strength by pitting and cracking.

• Temperature - Low temperature reduces chain

strength by embrittlement. Going in and out of

cold storage results in moisture from

condensation.

• Chemical Solutions or Vapors - Corrosive attack

on the chain components and/or the mechanical

connections between the chain components.

Cracking can be (and often is) microscopic.

Going from microscopic cracking to complete

failure can be either abrupt or may require an

extended period of time.

• Abrasives - Accelerated wearing and scoring of

the articulating members of the chain (pins and

plates), with a corresponding reduction in chain

strength. Due to the inaccessibility of the bearing

surfaces (pin surfaces and plate apertures),

wear and scoring are not readily noticeable to

the naked eye.

MY5510

5

5

MY3620

A

B

WARNING

Worn pins, stretched or cracked links or corrosive

environments can cause chain failure. A chain failure

could result in uncontrolled boom movement, loss of

load or machine instability.