3 hydraulic pressure diagnosis, 1 pressure checks and adjustments, Hydraulic pressure diagnosis – JLG G6-42A Service Manual User Manual

Page 138: Section 8.3.1, “pressure checks and adjustments, Pressure checks and adjustments

Hydraulic System

8-4

G6-42A, G9-43A, G10-43A

8.3

HYDRAULIC PRESSURE DIAGNOSIS

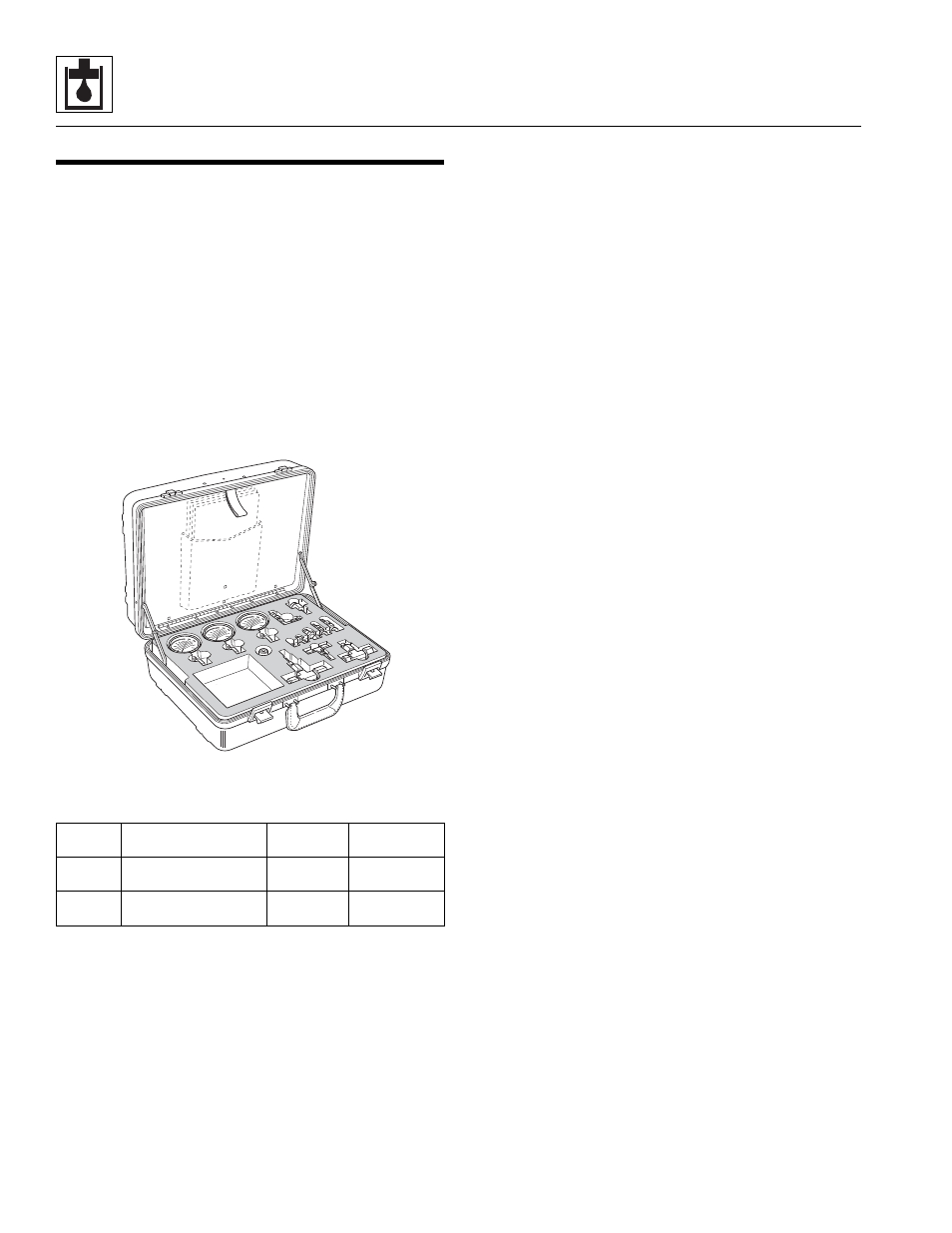

JLG Parts Department has a kit available to use for

hydraulic system maintenance and troubleshooting: the

JLG Pressure Test Kit. The kit is contained in a durable

polyethylene carrying case for demanding field service

conditions.

Pressure Test Kit

The hydraulic pressure test kit is used to pressure test the

various hydraulic components in the hydraulic system.

The kit includes:

• Gauges for testing high and low pressure circuits

• Fittings, couplers and hoses

• Durable carrying case

Contact your local authorized distributor for ordering

information.

8.3.1

Pressure Checks and Adjustments

When diagnosing trouble in the hydraulic system, use the

hydraulic testing information in Section 8.4.1, “Hydraulic

Pressures.”

In general, follow the steps below whenever conducting

pressure checks and performing adjustments:

1. Park the machine on a firm, level surface. Engage

the park brake, place the travel select lever in (N)

NEUTRAL, level the boom and turn the engine OFF.

2. The test port is located at the top right corner of the

main control valve. Install a pressure gauge capable

of measuring at least 10% more pressure than that

which the circuit being checked operates under.

3. Start the engine. Operate machine functions several

times to allow hydraulic oil to reach operating

temperature. The hydraulic oil temperature should

be between 100-120°F (38-49° C). If a temperature

gauge or thermometer is unavailable, the hydraulic

oil reservoir should be warm to the touch.

4. Refer to Section 8.4.1, “Hydraulic Pressures,” for

testing procedures.

5. Fully depress the accelerator pedal if required. Place

and hold the joystick in the position needed to

operate the particular machine function being

checked. Continue holding the joystick in position

until pressure readings are taken.

6. Check the pressure gauge reading. It should read as

specified in the Pressure Readings column of the

charts found in Section 8.4.1, “Hydraulic Pressures.”

If the reading is not as specified, turn the engine

OFF and check other components in the system.

Verify that all related hydraulic components and

electrical switches, sensors, solenoids, etc. are

operating correctly.

7. Adjust the relief valve by turning the adjustment

screw clockwise will increase the pressure; turning

the screw counterclockwise will decrease the

pressure.

8. Start the engine and check the pressure again. Turn

the engine OFF. If there is pressure reading in the

gauge, bleed it off then disconnect or remove the

pressure gauge from the machine.

Part

Number

Description

Approximate

Weight

Price and

Availability

70000652

Hydraulic Pressure Test

Kit

10 lbs.

Consult Factory

70000101

Digital Hydraulic

Pressure Test Kit

7 lbs.

Consult Factory

MZ1460