13 forks, Forks – JLG G12-55A Service Manual User Manual

Page 63

3-29

G10-55A, G12-55A

Boom

3.13

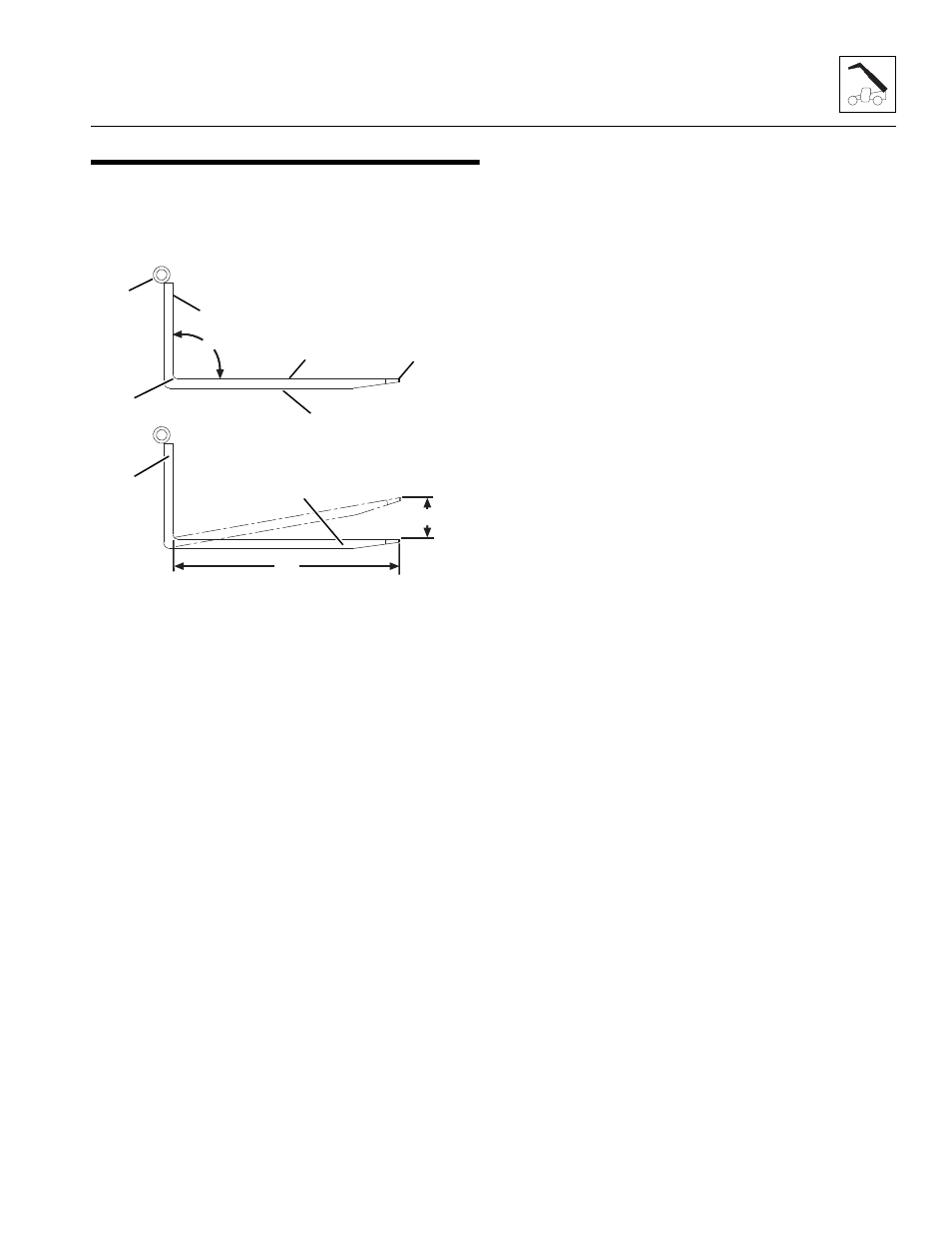

FORKS

Forks should be cleaned and inspected prior to being

attached to carriage. If the following criteria is not met,

forks must be removed from service immediately.

Daily Inspection

1. Inspect forks (1) for cracks, paying special attention

to heel (2) and mounting tubes (3).

2. Inspect forks for broken or bent tips (4) and twisted

blades (5) and shanks (6).

Yearly Inspection

1. Straightness of the upper face of blade (5) and the

front face of shank (6) should not exceed 0.5 percent

of the length of blade or height of shank.

2. Angle (7) between upper face of blade and front face

of shank should not exceed 93 degrees.

3. Thickness of blade (8) and shank (9) should not be

reduced to 90 percent of original thickness.

Note: Contact the local distributor with the fork part

number to find the manufactured dimensions of the fork

blade.

4. Ensure fork length (10) is adequate for intended

loads.

5. Fork markings should be legible, re-stamp if

required.

6. Compare fork tips (11) when mounted on a carriage.

Maximum difference in height of fork tips is 3 percent

of the length of the blade (10).

MH6460

3

2

6

7

5

1

4

9

8

10

11