JLG G12-55A Service Manual User Manual

Page 175

9-33

G10-55A, G12-55A

Electrical System

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Properly disconnect the battery.

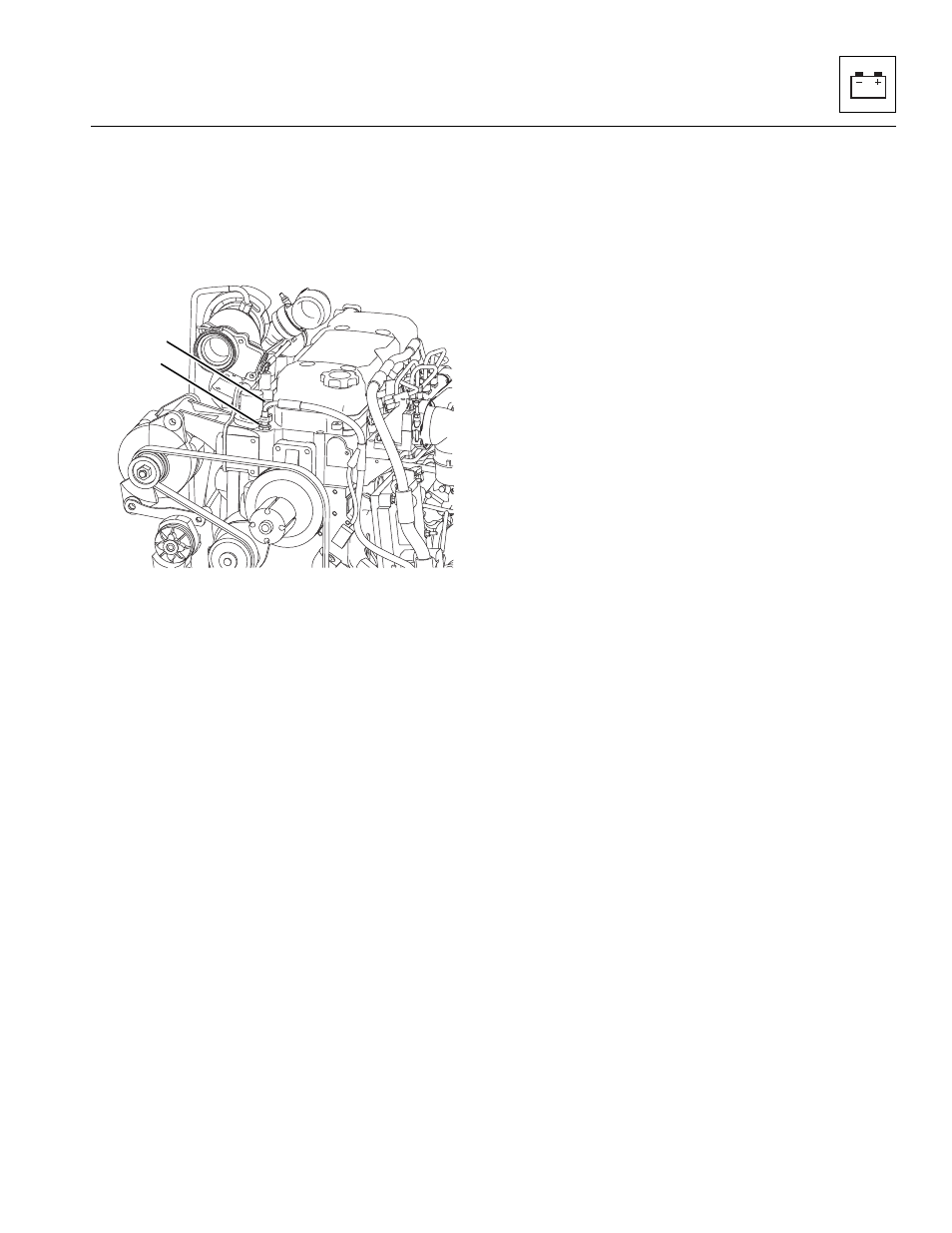

5. Unplug the engine coolant temperature sender

connector (1) from the wiring harness connector.

6. The engine coolant temperature sender (2) is

located near the upper radiator hose thermostat

housing and threaded into the engine block.

Remove the sender.

b. Engine Coolant Temperature Sender Inspection

and Replacement

Inspect the sender and the wiring harness connector

terminals for continuity. Replace a defective or faulty

sender with a new part.

c. Engine Coolant Temperature Sender Installation

and Testing

1. Thread the engine coolant temperature sender into

the engine block snugly, then connect the sender

connector to the wiring harness connector.

2. Properly connect the battery.

3. Check for proper coolant level.

4. Start the engine, allow it to reach operating

temperature and observe the operator’s instrument

cluster for warning indication. If the sender is not

defective, the problem could be elsewhere; possibly

in a shorted wire, improper-running engine, improper

or low coolant, obstructed or faulty radiator, coolant

pump, loose fan belt, defective instrument display,

etc.

5. Close and secure the engine cover.

6. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel.

MY4620

2

CUMMINS ENGINE SHOWN

1