Wire cable inspection, Wire cable inspection -16 – JLG X700AJ Operator Manual User Manual

Page 112

SECTION 6 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

6-16

– JLG Lift –

3128790

Wire Cable Inspection

A qualified technician shall conduct the following:

1. Remove all covers from the third boom section and two

boom extensions and inspect the wire ropes and pulleys

for any damage.

2. Wire cables when pulled on manually shall not move

more than an eighth (1/8) inch.

3. Wire rope torque is 10Nm

Inspection

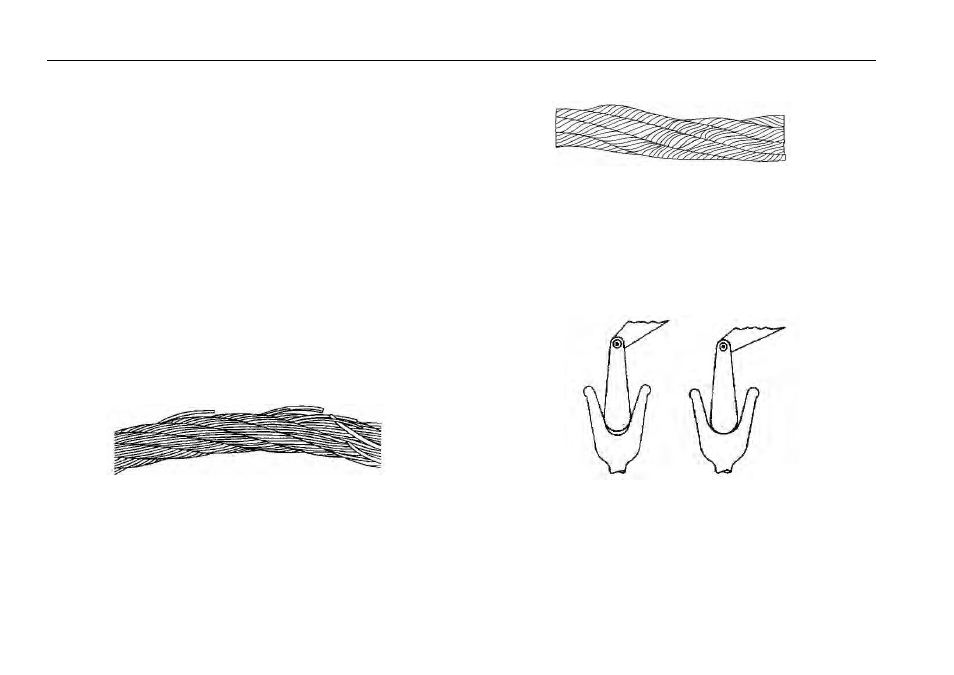

NOTE: The pictures in this section are just samples to show

the replacement criteria of the rope.

1. Inspect ropes for broken wires, particularly valley wire

breaks and breaks at end terminations.

NOTE: Flexing a wire rope can often expose broken wires

hidden in valleys between strands.

2. Inspect ropes for corrosion.

3. Inspect ropes for kinks or abuse.

NOTE: A kink is caused by pulling down a loop in a slack line

during improper handling, installation, or operation.

4. Inspect sheaves for condition of bearings/pins.

5. Inspect sheaves for condition of flanges.

6. Inspect sheaves with a groove wearout gauge for exces-

sive wear.

NOTE: Observe the groove so that it may be clearly seen

whether the contour of the gauge matches the con-

tour of the bottom of the groove.

7. Ropes passing inspection should be lubricated with wire

rope lubricant before reassembly.