Rubber track maintenance/replacement, Rubber track maintenance/replacement -13 – JLG X700AJ Operator Manual User Manual

Page 109

SECTION 6 - GENERAL SPECIFICATIONS AND OPERATOR MAINTENANCE

3128790

– JLG Lift –

6-13

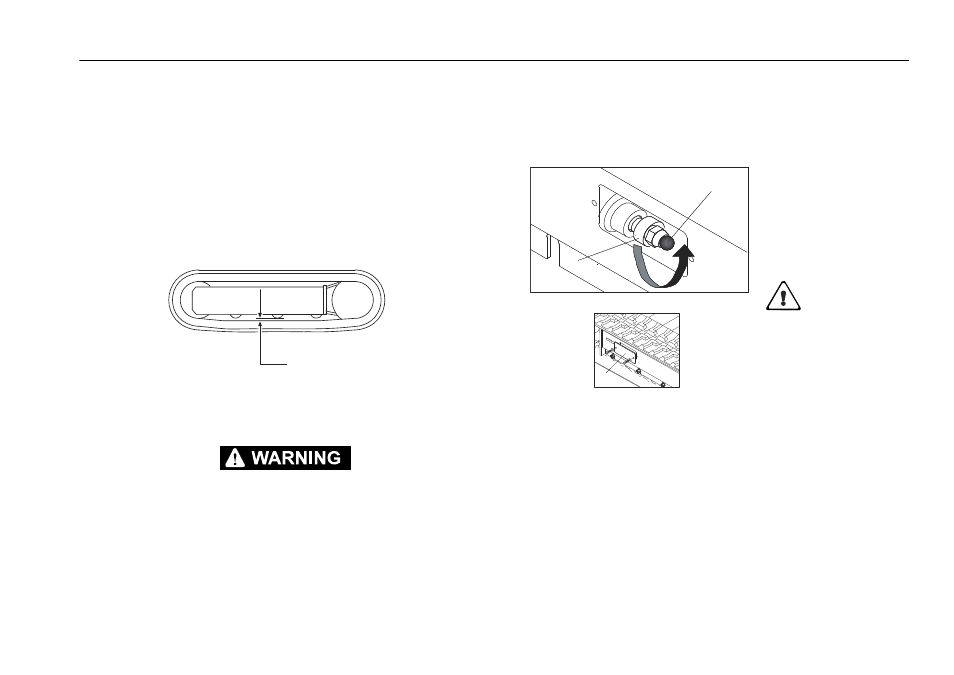

Rubber Track Maintenance/Replacement

Check track tension

Stop the machine on a firm, level, and uniform surface. Raise

the machine off the surface using the outriggers. Measure

distance A from the bottom of the roller to the inside of the

rubber belt. The rubber track tension is to be between

0.4inches (10mm) and 0.6 inches (15mm).

NOTE: If the track is out of tolerance immediately discontinue

use of the machine

THE GREASE CONTAINED WITHIN THE HYDRAULIC TRACK IS

PRESSURIZED. NEVER LOOSEN GREASING VALVE 1 MORE THAN

ONE (1) TURN. NEVER LOOSEN GREASE VALVE 2.

1. Ensure all debris has been removed between the wheel

teeth and track links.

2. Remove the screws from the adjustment access lid 3.

3. Loosening of the track.

4. Slowly unscrew valve 1 in the counterclockwise direction.

Do not exceed one (1) screw rotation.

5. If the grease does not begin to drain, slowly rotate the

track.

6. Once correct track tension has been achieved, turn

grease valve 1 clockwise to tighten valve.

7. Clean area of all trace grease.

A

3

1

2

PERICOLO

DANGER