5 loading a swing-bucket rotor, 6 closing the lid of the device, Loading a swing-bucket rotor – Eppendorf Concentrator plus (New Design) User Manual

Page 29: Closing the lid of the device, Operating manual

29

Concentrator plus/Vacufuge® plus — Operating manual

5.3.5

Loading a swing-bucket rotor

Requirement

•

A combination of rotor, bucket and adapter, approved by Eppendorf.

•

Two inserted buckets.

•

Matching and tested tubes and plates.

•

Adapters and plates with a total height of 27 mm

1. Check the bucket grooves for cleanliness and grease lightly with pivot grease (order no. int.:

5810 350.050 / North America: 022634330).

Dirty grooves and pivots prevent buckets from swinging out evenly.

2. Hang the buckets into the rotor.

3. Check that both buckets are hanging properly and can swing freely.

4. When using a plate type for the first time, carry out a manual loading and swing-out test.

5. Check maximum payload (adapter, plate and content) per bucket.

The relevant details can be found on the rotor and in this operating manual (see Rotors on

p. 11).

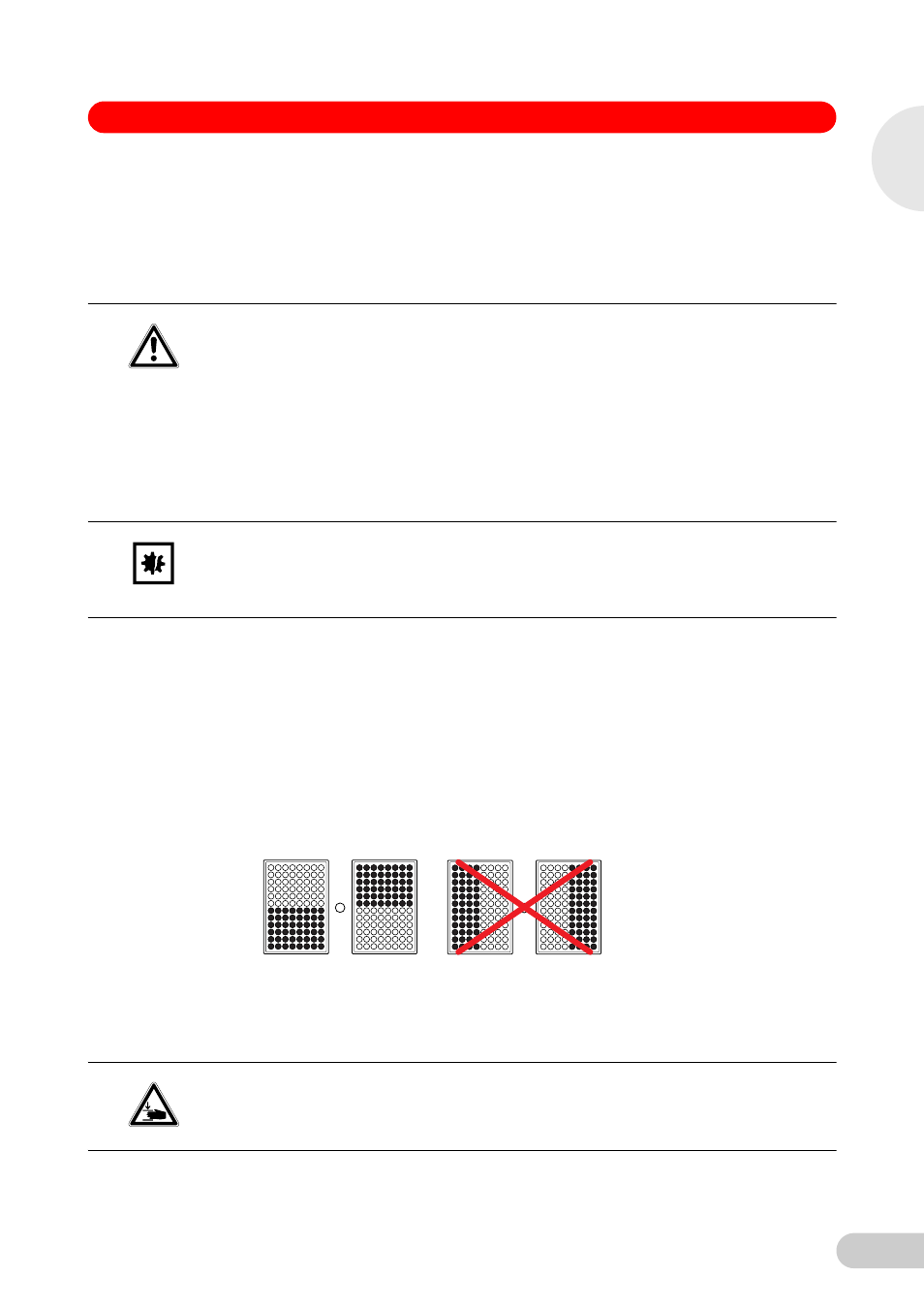

6. Load the buckets symmetrically when inserting adapters and plates.

The plate arrangement shown on the right-hand side is incorrect, as the buckets will not swing

properly.

The plates have some play in the buckets.

5.3.6

Closing the lid of the device

1. Check that the rotor is correctly positioned.

2. Close the lid of the device.

CAUTION!

Risk of injury from unsymmetric loading of rotors.

Load rotors symmetrically with identical tubes and/or buckets and plates.

Only load adapters with suitable tubes and/or plates.

Always use tubes and/or plates of the same type (weight, material/density and volume).

Ensure that tubes that are located opposite each other contain liquids with the same rate of

evaporation. Otherwise an imbalance can occur and the concentration may automatically stop.

Check for symmetric loading by balancing the adapters and tubes and/or plates used with

scales.

The device automatically detects imbalances during operation and stops the run immediately with

an error message and a signal tone. Check the load, balance the tubes and restart the run.

NOTICE!

Filling the plates too high can cause overflowing.

During the run the meniscuses in the tubes along the edges of the plates are at an angle. This is

due to the centrifugal forces and cannot be avoided.

Fill the wells of the plates to a maximum of 2/3 of the max. filling volume.

WARNING!

Device lid can crush. Keep hands clear.

Do not reach between the device and lid when opening or closing the device lid.

EN

O

perating manual