Removing propeller assembly from shaft, Typical motor current and starter size, See figure 9) – Aerovent IM-100 User Manual

Page 8: Table 1. tightening torque (lb-ft)

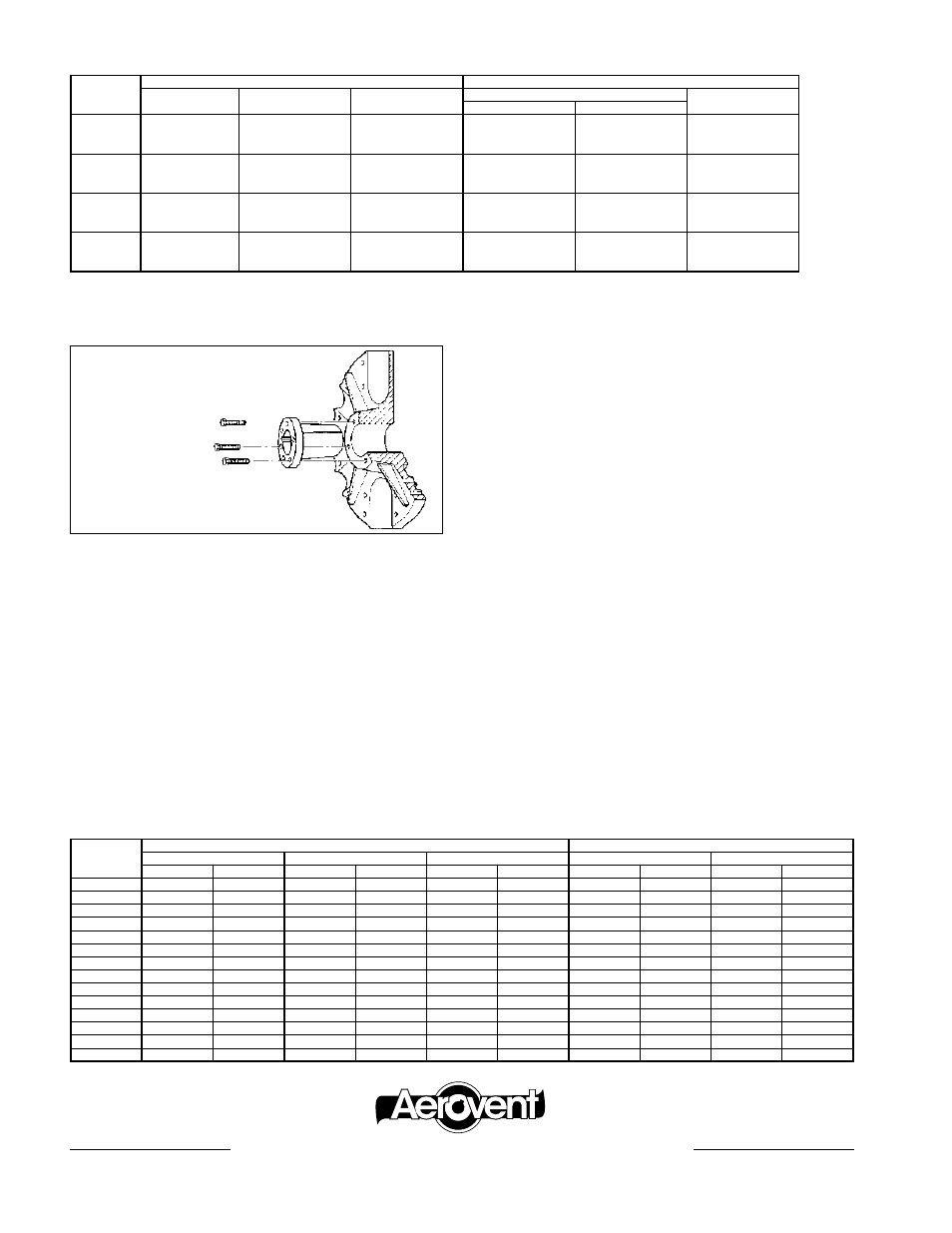

Removing Propeller Assembly

from Shaft

(see Figure 9)

1. Remove all capscrews from the propeller and hub

assembly.

2. Start capscrews into the threaded holes in the bush-

ing flange.

3. Tighten each bolt successively part of a turn to force

the propeller off the bushing. This forces the bushing

loose from the propeller and releases the compres-

sion so that the entire assembly will slide from the

shaft.

4. Pull the bushing off the shaft. If the assembly has

been in place some time, it may be necessary to use

a wheel puller to remove the bushing. Never use a

wheel puller on the propeller.

Typical Motor Current and

Starter Size

Amperes shown in the table below are nominal and

were used for sizing of the starters only. These values

are not to be used for sizing heaters or other overload

protection. Consult the motor nameplate for the correct

motor current and refer this to the heater size chart for

the particular starters used.

NOTE: When sizing overload heaters, conditions under

which the starters will operate must be considered.

Enclosed starters should have heaters one size larger

than open starters. Where enclosures are subjected to

external heat, such as radiant heat from the sun or

heat accumulation under a roof, it may be necessary

to increase the size even more. Experience with the

operating conditions and measurement of the actual line

current will aid in proper sizing of heaters.

Do Not Lubricate

Capscrews, Bore, or

Bushing Barrel

For Propellers Not Using A Taper Bushing

Consult The Specific Product Installation

Manual

For larger motor sizes, refer to National Electric Code.

Figure 9. Removing Propeller Assembly

Typical Motor Current and Starter Size

7.5MWG08/14

WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®

Table 1. Tightening Torque (lb-ft)

SIZE

FASTENER

GRADE 2

GRADE 5

GRADE 8

BROWNING SPLIT

QD

FOR DRIVE

IN IRON

IN ALUM. HUB

#10

—

—

—

—

—

5

1

⁄

4

-20

5.5

8

12

7.9

7.5

9

5

⁄

16

-18

11

17

25

16

13

15

3

⁄

8

-16

22

30

45

29

24

30

7

⁄

16

-14

30

50

70

—

—

—

1

⁄

2

-13

55

75

110

70

—

60

9

⁄

16

-12

—

—

—

—

—

75

5

⁄

8

-11

100

150

200

—

—

135

3

⁄

4

-10

170

270

380

—

—

—

7

⁄

8

-9

165

430

600

—

—

—

1-8

250

645

900

—

—

—

1

1

⁄

4

-7

500

1120

1500

—

—

—

HP

THREE PHASE

SINGLE PHASE

230V

460V

575V

115V

230V

AMPS

STARTER

AMPS

STARTER

AMPS

STARTER

AMPS

STARTER

AMPS

STARTER

1

⁄

4

00

00

00

5.8

00

2.9

00

1

⁄

3

1.7

00

0.9

00

00

7.2

00

3.6

00

1

⁄

2

2.0

00

1.0

00

0.8

00

9.8

0

4.9

00

3

⁄

4

2.8

00

1.4

00

1.1

00

13.6

0

6.9

00

1

3.5

00

1.8

00

1.4

00

16.0

0

8.0

00

1

1

⁄

2

5.0

00

2.5

00

2.0

00

20.0

1

10.0

0

2

6.5

0

3.3

00

2.6

00

24.0

1

12.0

0

3

9.0

0

4.5

0

4.0

0

34.0

1

17.0

1

5

15.0

1

7.5

0

6.0

0

28.0

1

7

1

⁄

2

22.0

1

11.0

1

9.0

1

40.0

2

10

27.0

2

14.0

1

11.0

1

50.0

3

15

40.0

2

20.0

2

16.0

2

20

52.0

3

26.0

2

21.0

2

25

64.0

3

32.0

2

26.0

2

Tolerance: +5%

The above torque values are for nonlubricated fasteners.

For wheel setscrews use Grade 2 values.

For bearing setscrews, use manufacturer’s recommendations.