Centrifugal fan alignment, Type cb & cba (swsi units), Type biub type ca, bw, ow, pb & hpb – Aerovent IM-100 User Manual

Page 7: Type aw, Type fc

Aerovent IM-100

7

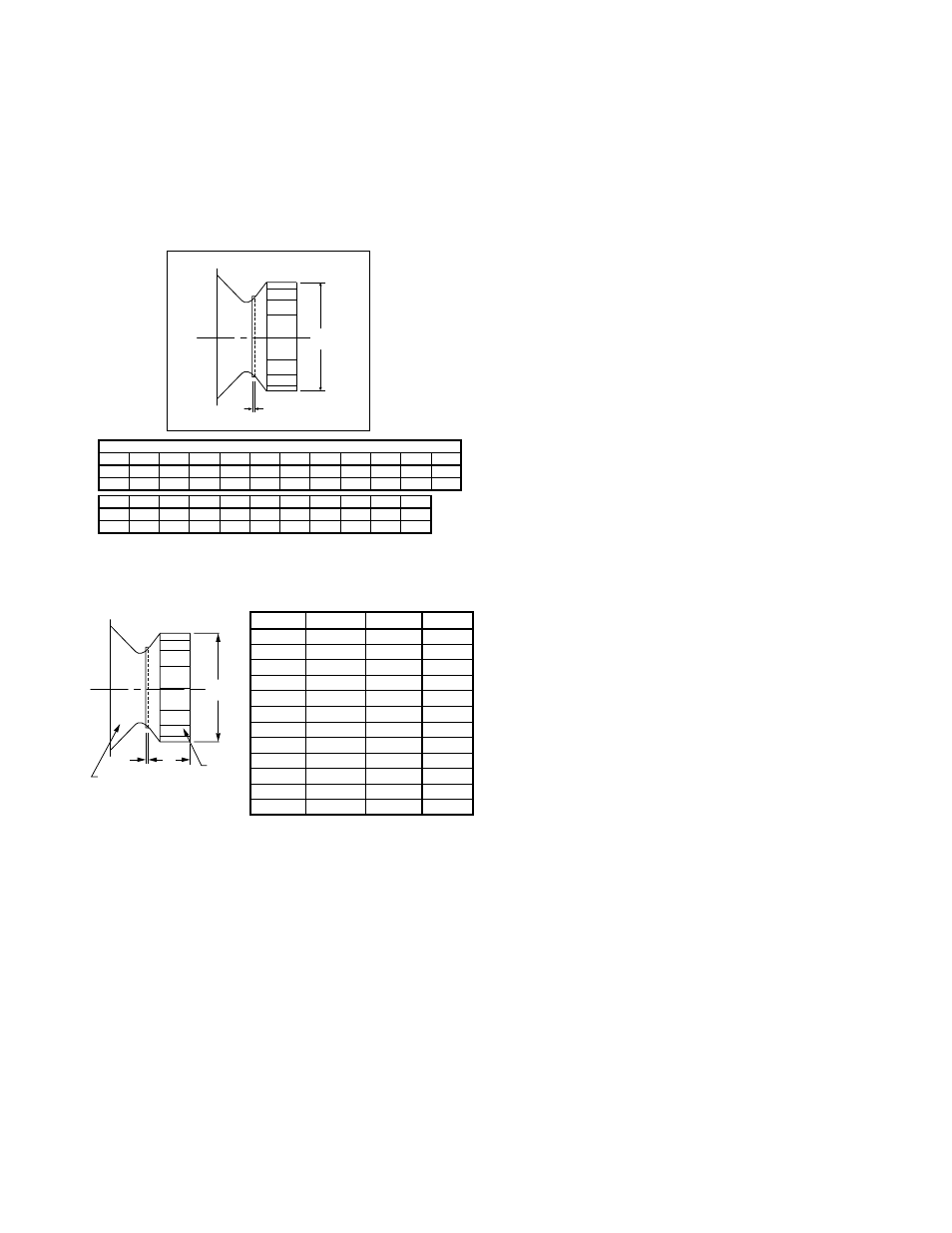

Centrifugal Fan Alignment

The fan shaft should be approximately centered in the

clearance hole in the fan housing and perpendicular to

the housing sides.

Adjust the clearance by moving the wheel axially

on the shaft. The following table indicates the correct

measurements for positioning the BI and BIA wheels.

Proper positioning is important in attaining correct fan

performance, particularly on the BI and BIA wheels.

Type CB & CBA (SWSI Units)

“B” dimension must be held. This dimension is critical

to fan performance.

Type BIUB

Type CA, BW, OW, PB & HPB

These radial blade wheels do not require precise posi-

tioning to attain the correct performance. The important

thing is to centrally locate these wheels axially within

the housing to insure adequate running clearance and

to maintain concentricity with the fan inlet.

Type AW

These wheels require a special inlet on the housing

which must extend into the wheel inlet flange to per-

form properly. Other than maintaining a minimum

1

⁄

4

"

overlap, adequate running clearance and concentricity

are all that is required.

Type FC

The forward curve blower employs a shallow venturi in

the housing to guide the air into the wheel. The depth

of this venturi is approximately one-tenth the wheel

diameter. Clearance between the wheel and venturi

should be the smallest allowable and still maintain nor-

mal running clearance. This axial separation is approxi-

mately

1

⁄

4

" and should be measured at four points

approximately 90° apart.

Installation Instructions for

Propellers Equipped with

Browning Malleable Iron Split

Taper Bushings

Many Aerovent fans are furnished with split taper bush-

ings for mounting the propeller to the shaft. When

properly assembled, the bushings grip the hub with

positive clamping action.

1. The bushing barrel and the bore of the propeller are

tapered. This assures concentric mounting and a true

running propeller.

2. Capscrews, when tightened, lock the bushing in the

propeller. Use special plated capscrews threaded full

length furnished by Aerovent.

3. The bushing is split so that when the locking cap-

screws force the bushing into the tapered bore, the

bushing grips the shaft with a positive clamping fit.

This will withstand vibration and punishing loads

without being loosened.

4. The propeller and bushing assembly is keyed to the

shaft and held in place by compression. This gives

added driving strength.

Before assembly, be sure that the shaft and key-

way are clean and smooth. Check the key size with

both the shaft and bushing keyways.

5. To assemble, put the capscrews through the clear-

ance holes in the bushing and put the bushing

loosely into the propeller. Do not press or drive. Start

the capscrews by hand, turning them just enough

to engage the threads in the tapped holes on the

propeller. Do not use a wrench at this time. The

bushing should be loose enough in the propeller to

move slightly. Slide the propeller and bushing assem-

bly onto the shaft, making allowance for end play

of the shaft to prevent rubbing. Install the key into

the keyway. Do not force the propeller and bushing

onto the shaft. If it does not go on easily, check the

shaft, bushing and key sizes once again.

Tighten the capscrews progressively with a wrench.

Do this evenly as in mounting an automobile wheel.

Tighten each capscrew part of a turn successively until

all are tight. These capscrews force the taper bushing

into the hub which in turn compresses the bushing onto

the shaft. This makes a positive clamping fit. The torque

must not exceed that shown in the table on page 8.

WARNING: Do not attempt to pull the bushing flange

flush with the hub end. There should be a clearance

which varies approximately

3

⁄

16

" to

1

⁄

4

" with the bush-

ing size when tightened. (Note: This is not a locating

dimension.)

A

DIA

B

B

A

DIA.

C

Inlet Cone

Wheel

SIZE

A

B

C

12

12.25

0.32

4.28

14

13.50

0.34

4.84

15

15.00

0.38

5.38

16

16.50

0.44

5.81

18

18.25

0.56

6.44

20

20.00

0.63

7.00

22

22.25

0.69

7.84

24

24.50

0.75

8.63

27

27.00

0.88

9.47

30

30.00

0.97

10.56

33

33.00

1.06

11.63

36

36.50

1.10

13.03

CB & CBA SWSI Wheel Placement

Size

122

135

150

165

182

200

222

245

270

300

330

A

12.25 13.50 15.00 16.50 18.25 20.00 22.25 24.50 27.00 30.00 33.00

B

0.32 0.34 0.38 0.44 0.56 0.63 0.69 0.75 0.88 0.97 1.06

Size

365

402

445

490

542

600

660

730

807

890

A

36.50 40.25 44.50 49.00 54.25 60.00 66.00 73.00 80.75 89.00

B

0.94 1.03 1.13 1.25 1.38 1.56 1.69 1.88 2.09 2.28