Motors, Lubrication instructions for ball bearing motors, Common causes of excessive vibration – Aerovent IM-100 User Manual

Page 2: Procedure for relubrication, Type of grease

2

Aerovent IM-100

All Aerovent fan assemblies are statically and dynam-

ically balanced to Balance Quality Grade G6.3. Each

fan is factory run tested for vibration in accordance

with ANSI/AMCA 204-96 "Balance Quality and Vibration

Levels for Fans" to Fan Application Category BV-3, to

the following peak velocity values, filter-in, at the fan

test speed:

Fan Application

Rigidly Mtd.

Flexibly Mtd.

Category

(in./sec.)

(in./sec.)

BV-3

0.15

0.20

While fans are test run and carefully balanced in

the factory, vibration cannot be guaranteed under field

conditions due to mounting and installation variables.

Vibration measurements, when possible, should be

taken at each fan shaft bearing in two planes per-

pendicular to the axis of rotation (planes to have 90

degree interval), and one measurement parallel to the

axis of rotation. On direct drive units, the perpendicular

measurements will be taken at each end of the motor

casing, taking care not to take measurements on the

fan shroud on TEFC motors. The axial measurement

can be taken on the motor foot or mounting base. In

some cases, primarily on axial flow units, it will not

be possible to take measurements at the bearings or

motor. On these units, the measurements should be

taken on the inner shell near the bearings. If this is not

possible, then take the readings on the outer shell near

the bearing locations.

If vibration is excessive, shut down the fan and

determine the cause.

Common Causes of Excessive Vibration

1. Support structure not sufficiently rigid or level.

Vibration amplified by resonance in ductwork or sup-

port structure.

2. V-belt drive misalignment. Belt tension is too tight or

too loose.

3. Bearing locking collar or mounting bolts loose.

Propeller set screw loose.

4. Material accumulation on propeller.

5.

Centrifugal Fans: Wheel rubbing on inlet cone.

Motors

Most integral horsepower totally-enclosed motors have

drain plugs in the end bells for drainage of condensa-

tion. On all roof ventilators, the bottom or lower plug

has been removed for continuous drainage.

All other style fans are shipped with the drain plugs

installed. The user should remove the proper drain plug.

For horizontally mounted units with the motor in the

airstream, remove the downstream drain plug. For verti-

cally mounted units, remove the bottom or lower drain

plug.

With motors supplied by the user, drain plugs may

not have been provided. Check with the motor manu-

facturer regarding drainage and condensation.

Lubrication Instructions for Ball

Bearing Motors

Grease-lubricated bearings, as furnished, are adequate

for a long period of operation without relubrication. A

good maintenance schedule for regreasing will vary

widely depending on motor size, speed and environment.

The table below suggests relubrication intervals for

motors on normal, steady running, light duty indoor

loads in relatively clean atmosphere at 40°C (105°F)

ambient temperature or less. Fractional horsepower

motors follow a schedule similar to that shown under

frames 143T to 215T.

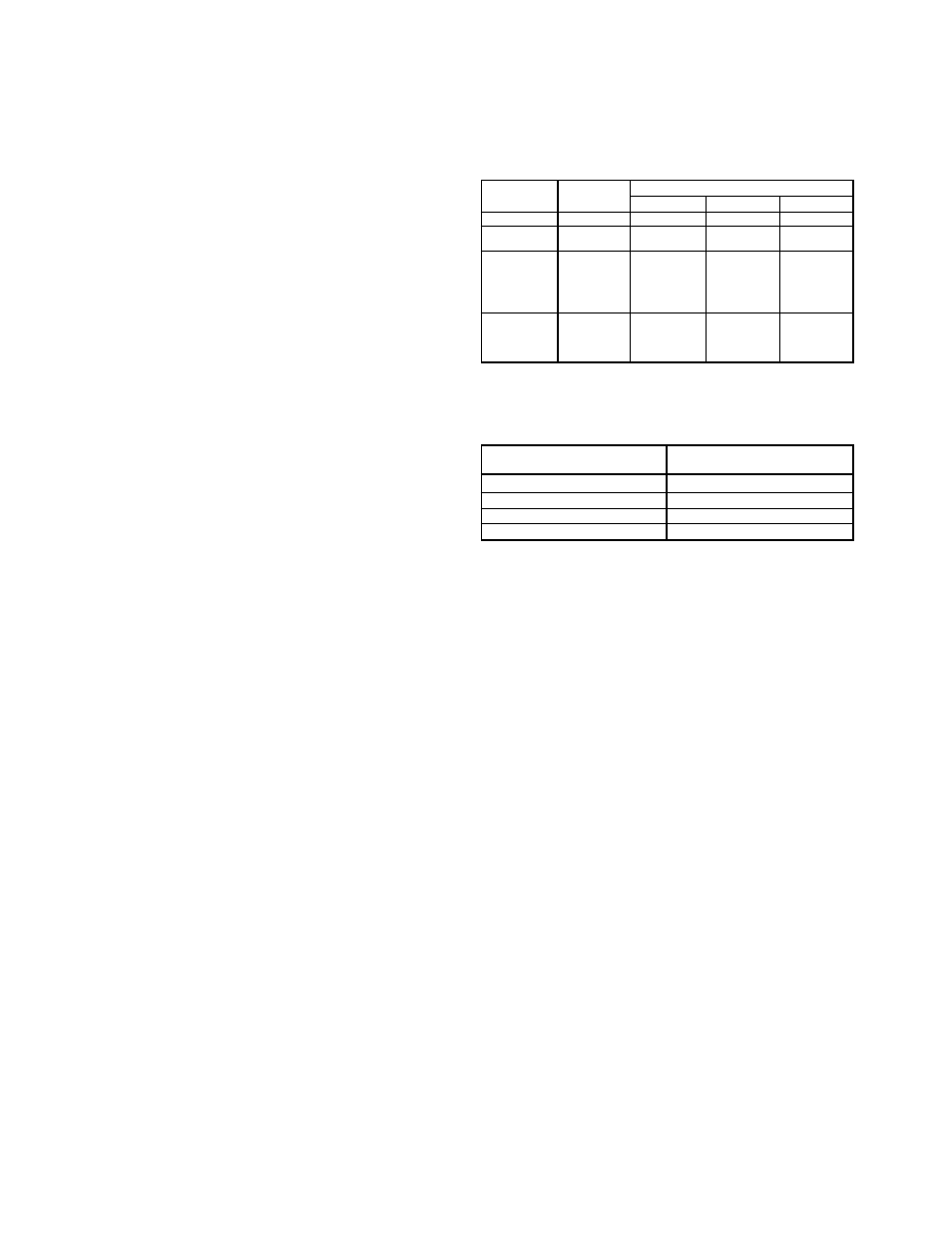

Motor Lubrication Intervals

TYPE OF

INSULA-

FRAME SIZE

ENCLOSURE

TION

143T–215T

254T–326T

364T–449T

Open-DP

B

2 yrs.

18 mos.

1 yr.

Enclosed-FC

B

Open-DP

F

18 mos.

1 yr.

9 mos.

Enclosed-NV

B

Enclosed-FC

F

Open-DP

H

1 yr.

9 mos.

6 mos.

Enclosed-Lint

Free-FC

B

Enclosed-NV

F

Enclosed-FC

H

Enclosed-Lint

9 mos.

6 mos.

3 mos.

Free-FC

F

NOTE: For motors over 1800 RPM, use

1

⁄

2

of tabled period. For heavy

duty, dusty locations, use

1

⁄

2

of tabled period. For severe-duty high vibra-

tion/shock, use

1

⁄

3

of tabled period.

VOLUME - REFERENCE TABLE

SHAFT DIAMETER

AMOUNT OF

(AT FACE OF BRACKET)

GREASE TO ADD

3

⁄

4

" to 1

1

⁄

4

"

1/8 cu. in. or 0.1 oz.

1

1

⁄

4

" to 1

7

⁄

8

"

1/4 cu. in. or 0.2 oz.

1

7

⁄

8

" to 2

3

⁄

8

"

3/4 cu. in. or 0.6 oz.

2

3

⁄

8

" to 3

3

⁄

8

"

2 cu. in. or 1.6 oz.

Motors with no provision for lubrication are equipped

with sealed bearings and require no maintenance.

Motors mounted in inaccessible locations are provided

with extended grease lines to facilitate lubrication if

provisions for lubrication are provided. The bearings are

equipped with relief fittings to prevent over-lubrication.

The grease lines are filled with lubricant at the factory.

Procedure for Relubrication

1. Stop motor.

2. Remove grease relief plugs in bearing housings.

3. Grease with hand gun until new grease appears at

relief hole.

4. Run motor for ten (10) minutes before replacing relief

plugs.

CAUTION: Do not over-lubricate. This is a major cause

of bearing and motor failure. Make sure dirt and con-

taminants are not introduced when adding grease.

Type of Grease

Lubricate with the following greases or their equivalent:

Amoco Rykon Premium #2

Chevron BRB-2 – Standard Oil or Calif.

SRI-2 – Standard Oil Company

Gadus S2 V100 2 - Shell Oil Company

Mobilith AW2

For motors lubricated with special greases, check lubri-

cation tag on motor.