Lubrication instructions for fan ball bearings, Storage of equipment, Fan bearings – Aerovent IM-100 User Manual

Page 3: Motors

Aerovent IM-100

3

Lubrication Instructions for

Fan Ball Bearings

Bearings and grease lines on belt driven fans are lubri-

cated in assembly. When lubrication is required, add

grease slowly while the shaft is rotating until grease

comes rapidly out of the seal.

For extreme conditions, lubricate according to experi-

ence. For normal conditions, lubricate the bearings with

Mobilith AW2 or an equivalent.

Bearings and grease lines on axial fans that are

ordered for high moisture or above normal temperatures

have been lubricated with a special lubricant, Plastilube

#2. Lubricate at regular intervals with Plastilube #2 as

indicated in the special lubrication chart listed below.

Plastilube #2 is available from Sulflo, Inc. 1158 Erie

Avenue, North Tonowanda, New York 14120.

Storage of Equipment

Fan Bearings

Since bearings tend to “breathe” on equipment stored

in areas with other than a constant temperature, mois-

ture will condense internally. Therefore, it is necessary

to keep the bearings completely full of grease and

periodically rotated to make certain that all internal

parts are coated with grease. Even a full bearing will

eventually pick up moisture and, therefore, must be

periodically purged with new grease.

Grease should be purged from the bearings to

remove condensed moisture, and the fan wheel rotated

by hand every thirty (30) days. This practice should be

done more often if weather is severe or if there is a

wide variation in temperature.

CAUTION IN PURGING: The fan should be rotated

while greasing and high pressure pneumatic greasers

should be avoided. See “Lubrication Instructions for Fan

Ball Bearings.”

To rotate the fan, follow the procedure listed below:

The blade marked number 1 should be rotated to

top center. The blade number and date should be

recorded in a log book which is to be stored in a

protective pouch attached to the fan. During storage,

the fan propeller should be rotated by hand at least

ten (10) revolutions every thirty (30) days to circulate

the lubricant in the bearings in the motor or on the fan

shaft. After the tenth revolution, stop with a blade at

top center which is not the same one as is listed for

the previous date in the log book.

Fans which are V-belt driven should be prepared for

storage as follows:

Carefully remove the belts, coil them (without kinks)

in matched sets and place them in a heavy carton.

Mark the carton with fan identification and store the

carton in a dry, well-ventilated area. Belts must not be

left exposed to sunlight or subjected to storage ambient

conditions exceeding 85°F, 70% relative humidity. Belts

which show signs of deterioration should be replaced

prior to startup. Before reinstalling belts, review the sec-

tion on “Belt Tension.”

NOTE: Procedures for storage of Aerovent equipment

as outlined above are intended as a general guide only.

Storage conditions will vary depending on the loca-

tion. Common sense and practical experience should

determine to what extent the above procedures will be

followed.

Motors

Motors must be stored under cover in a clean, dry,

vibration-free location. Remove sufficient packaging

material to allow circulation of air around the motor.

Maintain the temperature of the windings a few degrees

above that of the surrounding air to protect against

condensation. If the motor is equipped with internal

heaters, the heaters should be energized throughout

the storage period to prevent this condensation. If

the motor does not have internal heaters, this can be

accomplished using any other safe, reliable method of

heating. Measure and record the ambient air tempera-

ture and winding temperature monthly.

In the event that the motor is not equipped with

internal heaters and space heating equipment is unavail-

able, wrap the motor as tightly as possible with heavy

duty polyethylene. Enclose bags of desiccant (such as

silicagel) with the motor to minimize moisture problems.

Check the desiccant regularly and replace it periodically

as dictated by climate requirements.

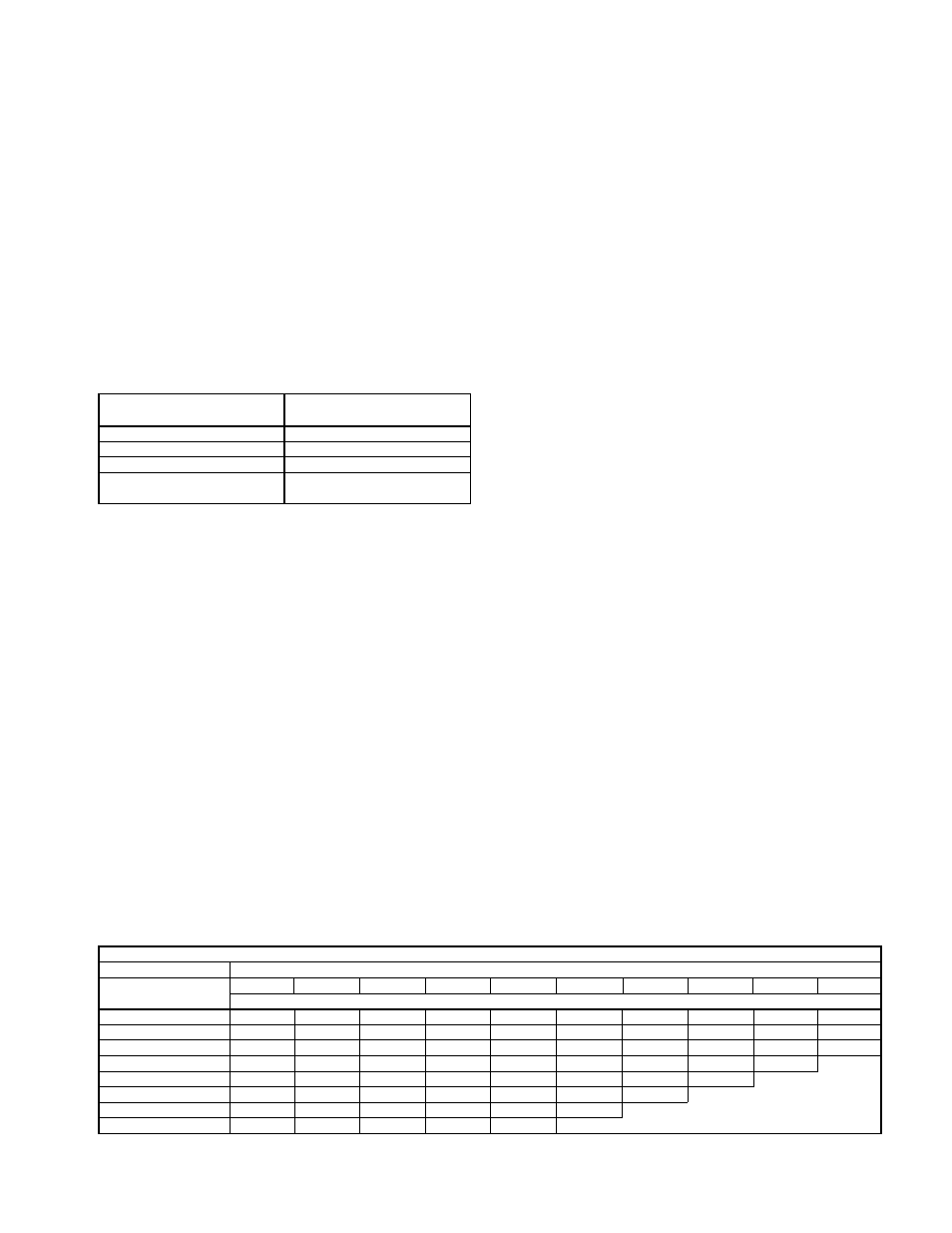

Lubrication Frequency for Horizontal Shaft Installations

(see Note for vertical shaft installations)

LUBRICATION FREQUENCY

OPERATING SPEED (RPM)

SHAFT SIZE

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

(INCHES)

RELUBRICATION CYCLE (MONTHS)

1

⁄

2

– 1

6

6

6

6

6

6

4

4

2

2

1

1

⁄

16

– 1

7

⁄

16

6

6

6

6

6

6

4

4

2

1

1

1

⁄

2

– 1

3

⁄

4

6

6

6

4

4

2

2

2

1

1

1

7

⁄

8

– 2

3

⁄

16

6

6

4

4

2

2

1

1

1

2

1

⁄

4

–2

7

⁄

16

6

4

4

2

2

1

1

1

2

1

⁄

2

– 3

6

4

4

2

1

1

1

3

7

⁄

16

– 3

1

⁄

2

6

4

2

1

1

1

3

15

⁄

16

– 4

6

4

2

1

1

NOTES: Reduce this lubrication frequency schedule by half for vertical shaft installations.

Consult manufacturer for specific recommendations.

Special Lubrication Frequency For

High Temperature and High Moisture

AIRSTREAM

TEMPERATURE

HOURS

TO 250°F

4500

TO 350°F

1500

TO 500°F

1000

WET ATMOSPHERE AT

ROOM TEMPERATURE

1000 TO 1500