Fan bearing replacement procedure, Replacing fan belts, Belt tension procedure – Aerovent IM-100 User Manual

Page 4

4

Aerovent IM-100

To prevent rusting of bearing parts, the rotor must

be rotated at regular intervals (30 days) to assure these

parts are well covered with oil or grease.

Prior to energizing the motor, it is to be inspected

and meggered by a motor manufacturer’s field service

engineer. The charges for this service to the customer

will be in accordance with the manufacturer’s published

service rates in effect at the time of the inspection.

In addition, it is strongly recommended that the

motor manufacturer be contacted for specific long-term

storage instructions.

Fan Bearing Replacement

Procedure

It is important to follow the assembly and alignment

procedure when making an installation of replacement

bearings. Inspect the shaft for wear at the bearing

mounting positions. Shaft diameter should not be under-

sized more than commercial ground and polished toler-

ances. Excessive undersizing will result in rapid wear.

1. Place new bearings loosely on the shaft. Locking

collars may be located on either end of the bearings

for ease of installation. The illustration shows one

locking collar on the drive end and one locking collar

on the fan end which is typical for a tubeaxial type

fan. A typical SWSI centrifugal fan would have both

collars mounted on the sheave side of the bearings.

Drop the mounting bolts in place, snug them and

adjust the position of the shaft with proper spacing

at either end.

2. Center both ends of the shaft in the housing of

tubeaxial fans using the propeller as a guide. On

centrifugal fans, the shaft is positioned 90° to the

scroll side with the wheel inlet centered in the scroll

inlet. Use the clearance in the mounting holes for

horizontal adjustment and shims, if necessary, for

vertical adjustment.

3. Tighten the bearings to the base plate and check

the position of the shaft again. Before tightening the

locking collars, be sure the shaft and bearings are in

proper alignment. The shaft should slide freely end

to end.

4. Tighten the eccentric cam locking collar of the bear-

ing at the propeller/wheel end. (The locking collar

design provides a positive lock of the wide inner

ring bearing to the shaft. To tighten, turn the locking

collar in the direction of shaft rotation to the lock

position, then tighten the collar set screw.) Repeat

this procedure for the sheave end locking collar on

DWDI and open wheel centrifugals. For other fan

types, proceed to Step 5.

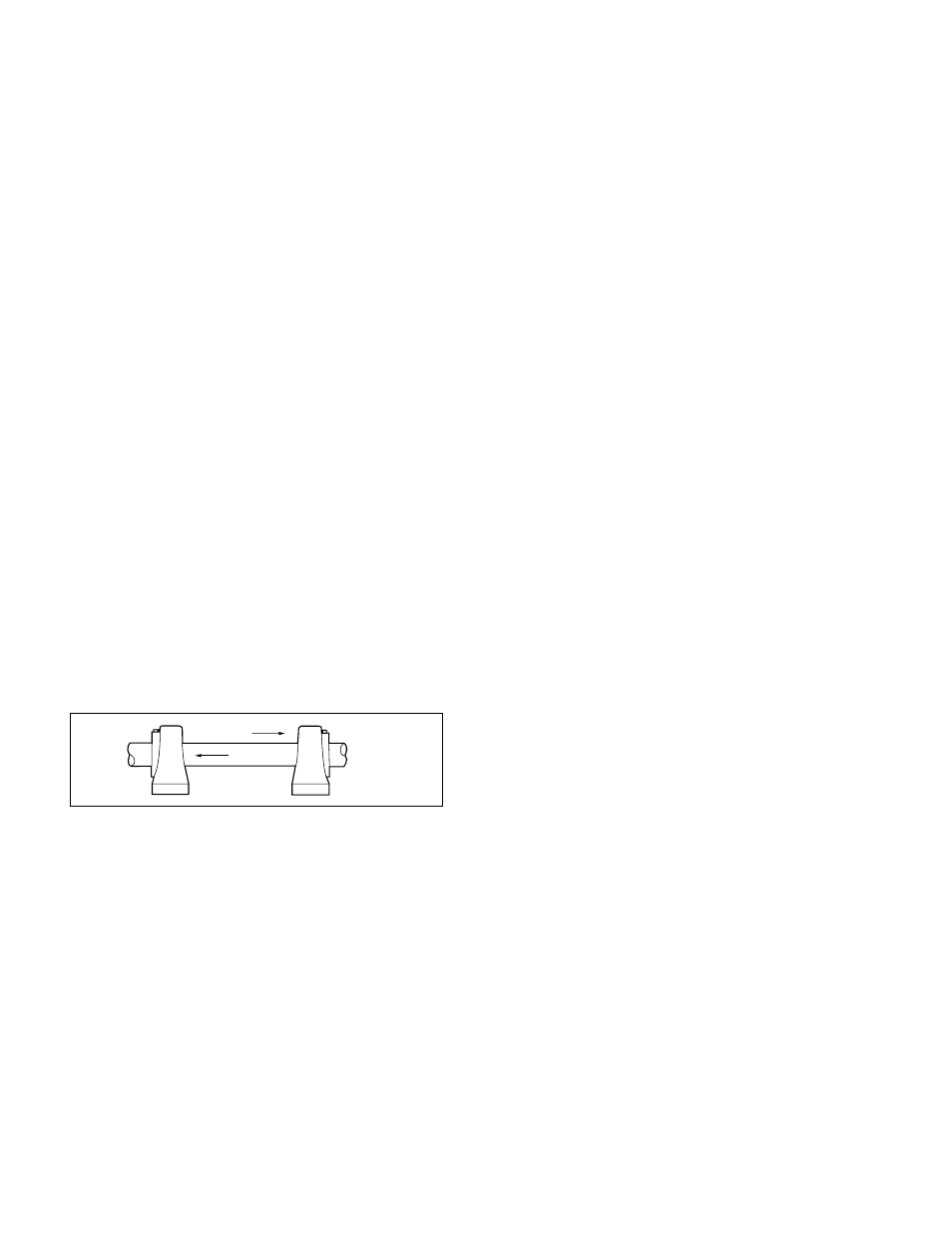

5. Axial flow propellers and single inlet centrifugal

wheels with back plates exert an air thrust toward

the fan inlet. (See Figure 1.) To help balance the

bearing loading, we allow the fan end bearing (belt

driven units) to carry the majority of this thrust load-

ing while the sheave end bearing carries most of

the radial load. (Direct coupled units would be just

the opposite.) To accomplish this, grasp the sheave

end of the shaft and pull or push on it toward the

fan inlet. At the same time, tap the locking collar of

the sheave end bearing (fan end on direct coupled

units) in the opposite direction with a soft mallet.

6. The final step is to tighten the sheave end bearing

eccentric cam locking collar while maintaining con-

stant pressure on the shaft toward the fan inlet.

For special heavy duty bearings, a spring locking

collar is used. The two knurled cup-point set screws

extend through the inner ring of the bearing and lock

firmly onto the shaft. Tighten the propeller end collar

first, then take hold of the sheave end of the shaft, pull

and then tighten the locking collar. The locking collar is

tightened by using the two set screws mentioned above.

Replacing Fan Belts

Worn belts may be easily replaced without removing the

fan from the system.

1. Loosen the motor hold-down bolts and move the

motor toward the fan. (This is done by turning a

jackscrew which is a part of the motor base on mod-

els having larger motors.) The belt may be slipped

off the motor sheave and then easily removed from

the sheave on the propeller shaft.

2. Check the numbers on the belt and make the

replacement with a belt having the same length and

section.

3. Adjust the motor outward to tighten the belt (see

instructions on belt tension, below) and tighten the

motor hold-down bolts. Be sure that the motor is

not cocked at an angle and that the end face of

the motor sheave is parallel to the end face of the

driven sheave.

Belt Tension Procedure

Belt tension is very important to the proper operation of

a fan and to the service life of a V-belt drive. A new

fan will be received with its belts properly adjusted;

however, all V-belts stretch in the first few hours of

operation. It is necessary to readjust the belt tension

after eight hours of running. After 100 hours the belts

should again be adjusted. Thereafter, periodic inspection

is recommended so belts may be adjusted or replaced

when necessary.

1. To adjust the belts, loosen the motor hold-down

bolts. Tighten the belt using the motor base adjusting

screw until the belt appears to be taut. You should

be able to deflect the belt slightly by squeezing the

two sides between thumb and forefinger and the belt

should snap back into position when released.

2. Retighten the motor hold-down bolts and start the

fan. If the belt screeches on startup it is too loose

and should be tightened further.

3. Allow the fan to run for a while, stop the fan, and

check the temperature of the sheave with your hand.

If the sheave is too hot to touch, the belt is probably

too tight.

V-belt drives on Aerovent fans are purposely sized to

handle considerably more load than would be necessary

for normal drive design. This is done to prolong the

life of the drive and provide for minimum maintenance.

Belts should be replaced when they have obviously

become worn, even though they are still operating.

A badly worn belt will also cause undue wear of the

Figure 1. Two Bearing Drive

Airflow

Thrust