Flexible couplings, Propeller/wheel alignment, Propeller fan alignment – Aerovent IM-100 User Manual

Page 6

6

Aerovent IM-100

3. Sheaves must have no noticeable eccentricity.

4. Belts must have the proper tension. Belts either too

loose or too tight cause vibration and excessive wear

(Figure 5). See instructions for belt tension adjust-

ment procedure.

5. After proper installation of drives, recheck the com-

plete assembly for smoothness of operation.

Flexible Couplings

Direct-coupled fans, which are received factory assem-

bled, on a common base plate, are accurately aligned

before shipment. However, base plates are flexible to

some extent and therefore must not be relied upon to

maintain the factory alignment. Realignment is neces-

sary after the fan has been leveled, grouted, and the

foundation bolts tightened. Also, check the lubricant,

where applicable, following the manufacturer’s recom-

mendations for the type and amount of lubricant.

For field installation, the coupling should be mounted

as follows:

1. Remove dirt or rust from fan and motor shafts and

coat with grease or oil for ease of mounting.

2. Check fan and fan shaft alignment, making sure that

the bearings are secure. Mount the fan shaft cou-

pling half flush to the end of the shaft and secure.

3. Mount the motor shaft coupling half flush to the end

of the shaft and secure.

4. Move the motor into position, with the coupling faces

separated by the coupling manufacturer’s specified

gap.

5. With a straightedge, tapered wedge, or a feeler

gauge, check for parallel and angular alignment

(Figure 6a).

6. Align the shafts until a straightedge appears to be

parallel to the shafts. Repeat at three additional

points at approximately 90° from each other (Figure

6b). Recheck the hub separation gap.

7. For more accurate alignment, use a dial indicator

clamped on one hub. With the dial button resting on

the other hub, rotate the hub on which the indicator

is clamped and observe the indicator reading. Take

readings at four locations, 90° apart. With correct

alignment, the faces of the couplings should be par-

allel within 0.002".

8. Once proper alignment is assured, secure the motor,

examine the alignment, complete the assembly, and

lubricate the coupling (when required) before putting

the unit into operation.

Propeller/Wheel Alignment

Fans, which are received factory assembled, have the

propellers already aligned and in place before shipment.

However, fans being flexible to some extent are some-

times subject to movement during shipment. To insure

smooth operation and proper performance, the following

propeller alignment should be checked before putting a

fan into operation.

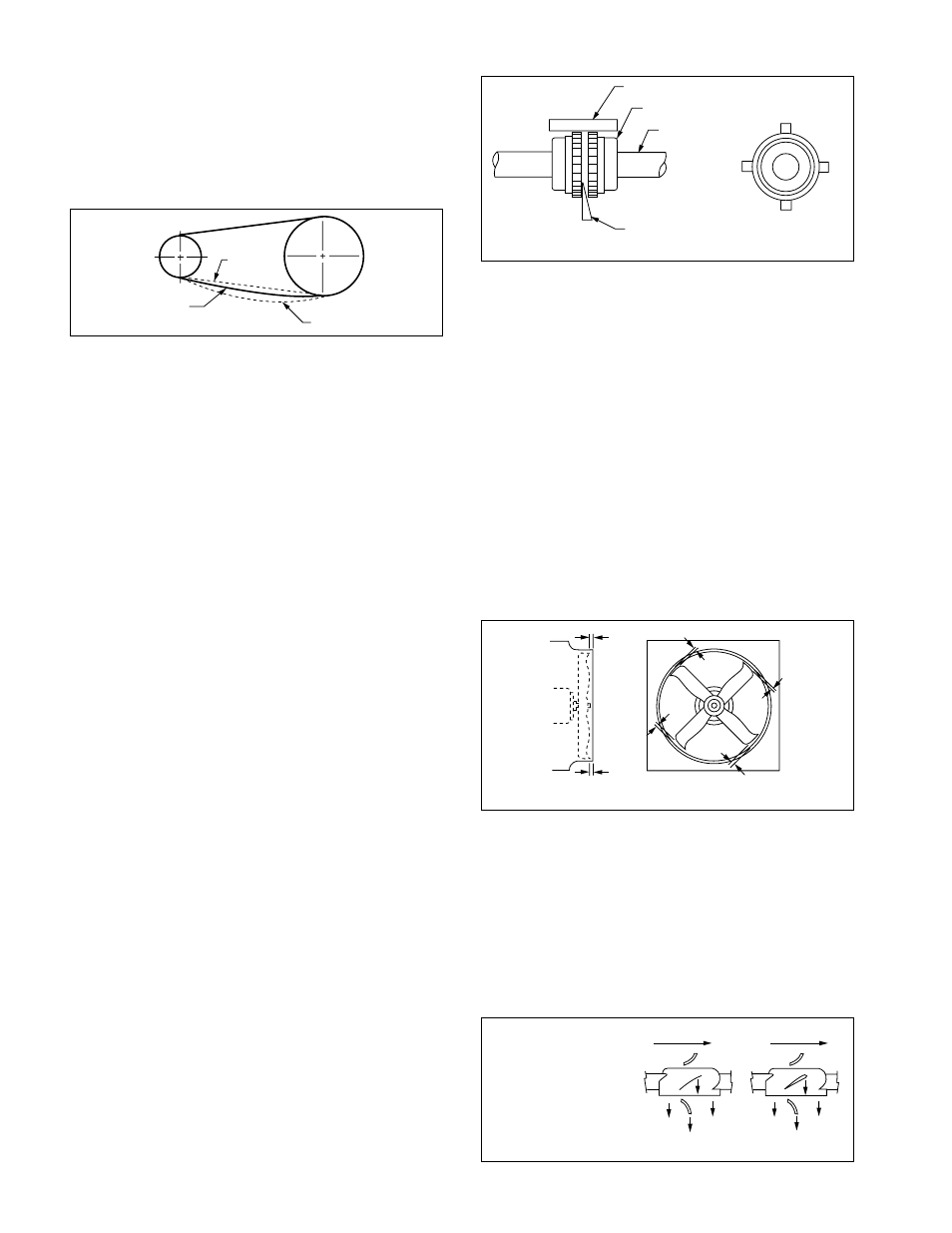

Propeller Fan Alignment

The fan shaft should be centered and parallel to the fan

casing. Center by checking gap (B) between the propel-

ler tip and the fan casing. Repeat at three additional

points at approximately 90° from each other (Figure

7b). Parallelism can be observed by measuring the

axial distance (A) from one blade to the end of the fan

casing at four points at approximately 90° from each

other (Figure 7a).

Do not confuse parallelism with blade track (axial

deviation of one blade to another). Blade track can be

checked by measuring the axial distance from one point

on the fan casing to the same point on each blade as it

passes by. (Some blades are mistracked for balancing.)

While checking the propeller alignment, it is good

practice to check its rotation. Normally the fan rotation

is marked by arrows on both the propeller and the fan

casing. If omitted, obliterated, or misapplied, check for

proper rotation as in Figure 8.

Figure 8. Checking for Proper Rotation

Too Loose

Slight Bow

Too

Tight

Figure 5. Proper Belt Tension

A

A

B

B

B

B

Figure 7. Propeller Fan Alignment

7a

7b

Figure 6. Flexible Coupling Alignment

Straightedge

Coupling

Shaft

Steel Wedge

3

1

2

4

6a

6b

Inlet

Guide Vanes

Outlet

Guide Vanes

Airflow

Airflow

Rotation

Rotation

RH rotation.

Vaneaxial shown.

Standard propellers

similar, but less

guide vanes.