Adjusting variable pitch sheaves, V-belt drive alignment – Aerovent IM-100 User Manual

Page 5

Aerovent IM-100

5

sheave. Replace belts when they show definite signs

of wear; otherwise the sheaves will become worn to

the point where they also must be replaced. Never put

new belts on a badly worn sheave. This will reduce the

capacity of the drive and cause excessive belt wear.

Most Aerovent fans are provided with an adjusting

screw as a part of the motor base for easy setting of

belt tension. However, small fans or fans using small

horsepower motors may have only a slotted base plate.

When the belt tension is adjusted by moving a motor

on a slotted base, be sure to block the motor tightly

and squarely before tightening the hold-down bolts,

keeping the motor sheave in line with the belt. The

motor sheave must be parallel to and in line with the

fan sheave.

When you make replacement of belts on a multi-

groove drive, be sure they are used in a matched set.

If you are not sure the belts are matched, observe them

in operation. The tight side should be perfectly straight

and the belts should run smoothly and in line. The slack

side should bow out and also be in line. If one of the

belts extends out considerably farther than another, it is

an indication that the belts are not matched and should

be changed. If there is only a slight difference, the nor-

mal stretching in the first hours of operation will equalize

the belt lengths and the belts will be well matched.

Adjusting Variable Pitch

Sheaves

Many Aerovent belt driven fans are furnished with

variable-pitch motor sheaves. Sheaves may be adjusted

for lower fan speeds without concern of overloading

motors. When adjusting sheaves to increase the fan

speed, check the motor current to be sure the motor

is not overloaded. Keep the motor current within the

nameplate and service factor ratings.

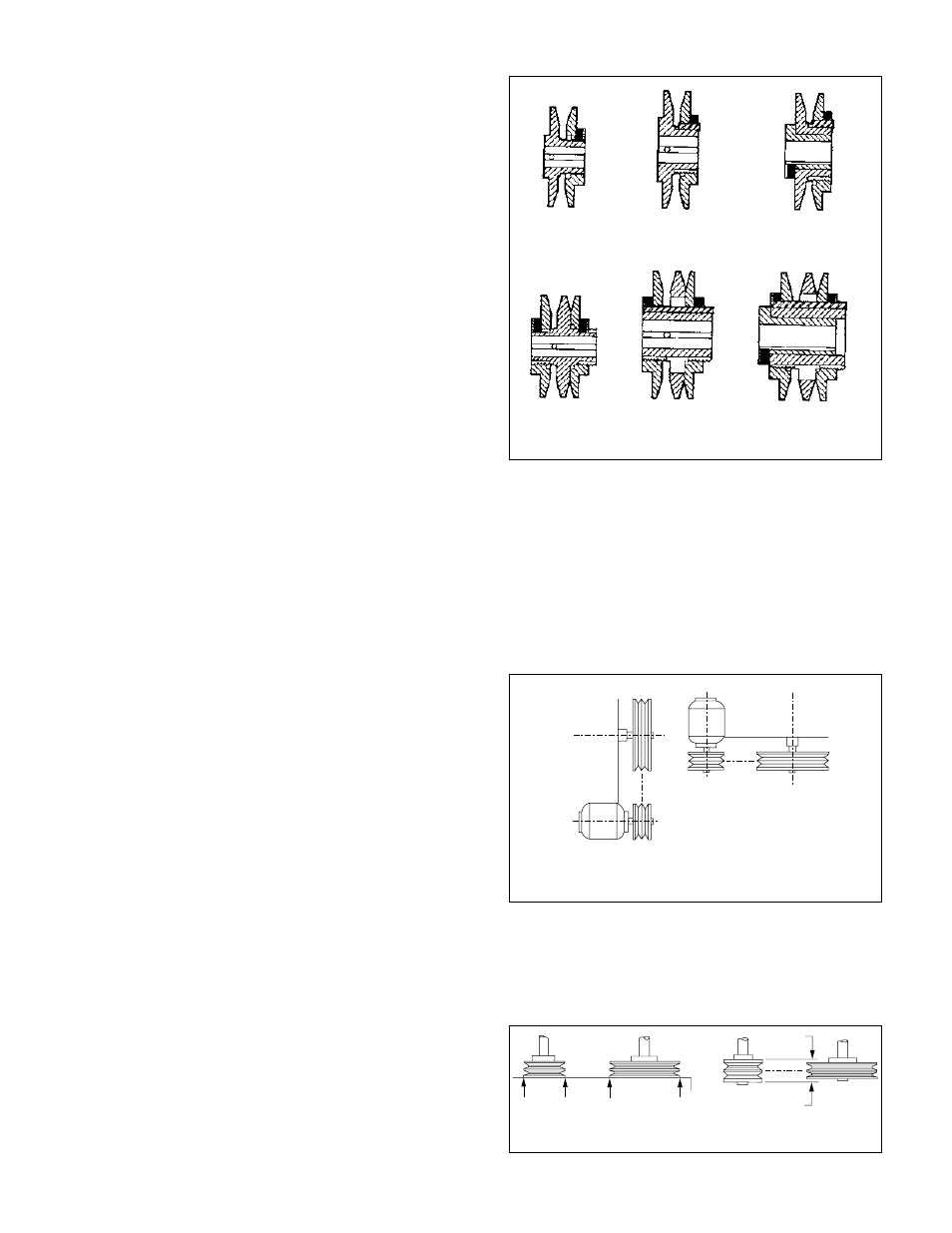

The sheaves used are easily adjusted. They come in

various styles, depending upon the size drive and motor

shaft. They are all fitted with hollow head knurled point

safety set screws.

The following steps should be taken to adjust the

pitch diameter.

1. Release belt tension and remove the belt or belts

from the sheave.

2. Loosen the set screw and remove the key hold-

ing the adjustable half of the groove (keys used on

styles 2, 3, 5 and 6 only). With styles 3 and 6, it

may be necessary to remove the sheave from the

shaft to remove the key.

3. Rotate the adjustable half of the sheave out for a

smaller pitch diameter (decreased speed) or in for a

larger pitch diameter (increased speed). Each one-

half turn will change the pitch diameter one-tenth

of an inch. Adjust two-groove sheaves the same

amount on each groove. 4L or A belts will oper-

ate satisfactorily with the sheave fully closed to a

maximum of five full turns open. 5L or B belts will

operate satisfactorily with the sheave one full turn

open to a maximum of six full turns open. (This will

insure full contact of the sheave in the groove.)

4. Replace the key and tighten the set screw to lock

the sheave half in position.

5. Replace the belts and tighten to the proper tension.

If an extreme amount of adjustment has been made,

it may be necessary to replace belts with another

length.

V-Belt Drive Alignment

Proper alignment and balance of the V-belt is as impor-

tant as a well-balanced propeller. To insure smooth fan

operation, the following should be checked:

1. The fan and motor sheaves must be in axial align-

ment. Shafts are parallel in both the vertical and

horizontal planes (Figure 3).

Figure 3. Fan and Motor Sheave Axial Alignment

2. The fan motor sheave must be in radial align-

ment. When sheaves are of equal width, align with

a straightedge (Figure 4a). When sheaves are of

unequal width, align the center of the sheaves (Figure

4b).

Figure 4. Sheave Alignment

Type 4

Type 5

Type 6

Finished Bore

Finished Bore

Bushing Type

S.S. in Keyway

Key Type

With Key

Type 1

Type 2

Type 3

Finished Bore

Finished Bore

Bushing Type

S.S. on Flat

Key Type

With Key

Drive

Fan

Motor

Drive

Fan

Motor

Top View

(Horizontal Alignment)

Side View

(Vertical Alignment)

Figure 2. Types of Sheaves

Straightedge Touching Sheaves

At Arrows

4a

4b