Modbus communication, Alert codes, 23 modbus communication – Bryan Boilers Triple-Flex High Efficiency Boilers & 300 User Manual

Page 35: 24 alert codes, Table 7 modbus terminals, Table 8 alert codes

Date:

8-4-2010

Revision: 0

Form:

2396

2.2.23 M

ODBUS

C

OMMUNICATION

The hydronic control Global Modbus port is a 3-

pin connector that interfaces to the following RS-

485 signals:

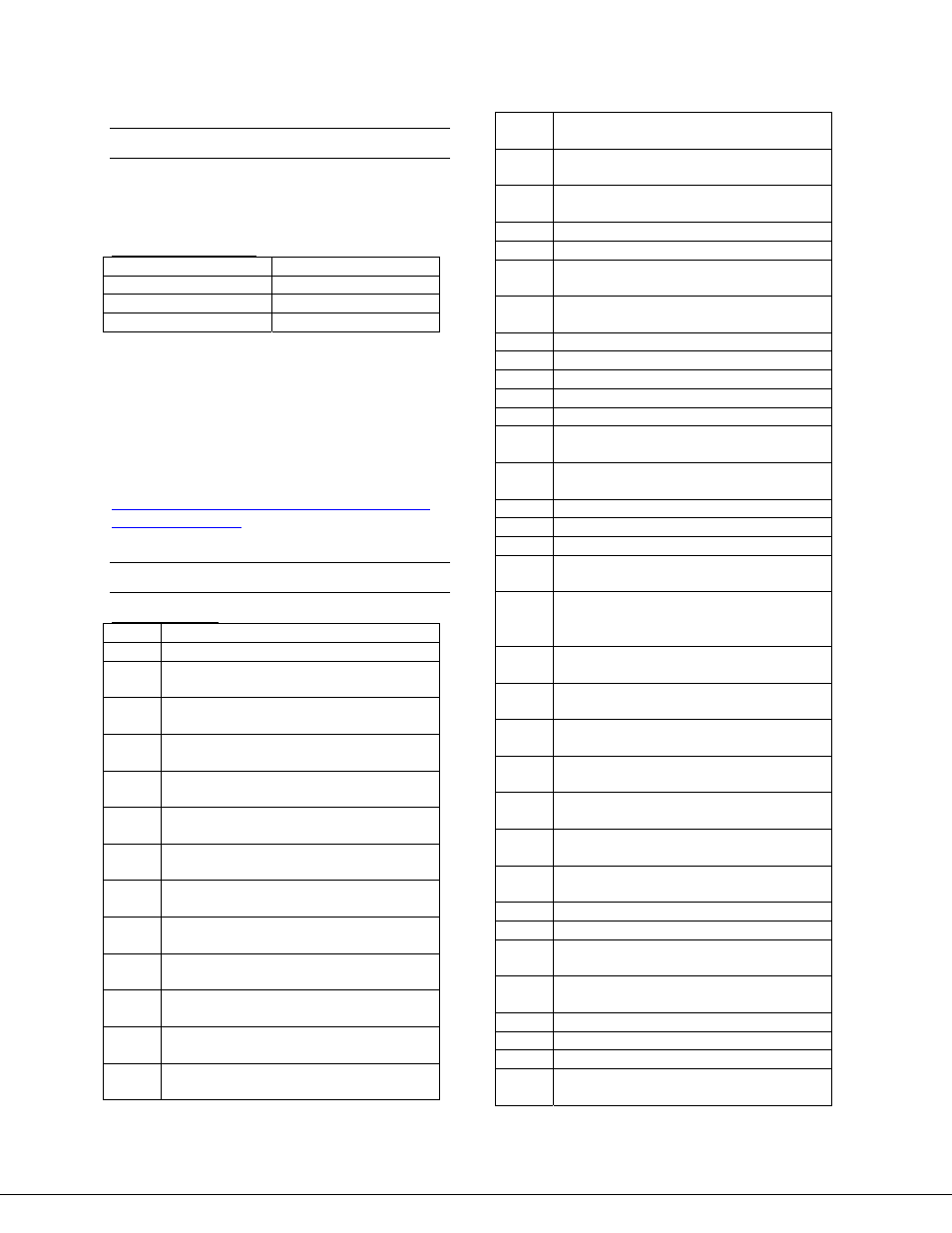

Table 7 Modbus Terminals

Signal Terminal

Data +

a

Data -

b

Common c

Modbus connections can be made at the display

(Figure 3 item 5) or the hydronic control (Figure

7 item 24).

For the modbus register map and other related

information please download Honeywell’s

R7910A product manual at:

2.2.24 A

LERT

C

ODES

Table 8 Alert Codes

29

Code Description

0

None (No alert)

1

Alert PCB was restored from factory

defaults

2

Safety configuration parameters were

restored from factory defaults

3

Configuration parameters were

restored from factory defaults

4

Invalid Factory Invisibility PCB was

detected

5

Invalid Factory Range PCB was

detected

6

Invalid range PCB record has been

dropped

7

EEPROM lockout history was

initialized

8

Switched application annunciation

data blocks

9

Switched application configuration

data blocks

10

Configuration was restored from

factory defaults

11

Backup configuration settings was

restored from active configuration

12

Annunciation configuration was

restored from factory defaults

13

Annunciation configuration was

restored from backup

14

Safety group verification table was

restored from factory defaults

15

Safety group verification table was

updated

16

Invalid Parameter PCB was detected

17

Invalid Range PCB was detected

18

Alarm silence time exceeded

maximum

19

Invalid safety group verification table

was detected

20-26 RESERVED

27

Safety processor was reset

28

Application processor was reset

29

Burner switch was turned OFF

30

Burner switch was turned ON

31

Program Module (PM) was inserted

into socket

32

Program Module (PM) was removed

from socket

33

Alert PCB was configured

34

Parameter PCB was configured

35 Range PCB was configured

36

Program Module (PM) incompatible

with product was inserted into socket

37

Program Module application

parameter revision differs from

application processor

38

Program Module safety parameter

revision differs from safety processor

39

PCB incompatible with product

contained in Program Module

40

Parameter PCB in Program Module is

too large for product

41

Range PCB in Program Module was

too large for product

42

Alert PCB in Program Module was

too large for product

43

IAS start check was forced on due to

IAS enabled

44

Low voltage was detected in safety

processor

45

High line frequency occurred

46

Low line frequency occurred

47

Invalid subsystem reset request

occurred

48

Write large enumerated Modbus

register value was not allowed

49

Maximum cycle count was reached

50

Maximum hours count was reached

51

Illegal Modbus write was attempted

52

Modbus write attempt was rejected

(NOT ALLOWED)