Warning – Burnham ALP150 User Manual

Page 68

68

H.

Purge Air From Gas Train

Upon initial start-up, the gas train will be filled with air.

Even if the gas line has been completely purged of air,

it may take several tries for ignition before a flame is

established. If more than 5 tries for ignition are needed,

it will be necessary to press the reset button to restart

the boiler. Once a flame has been established for the

first time, subsequent calls for burner operation should

result in a flame on the first try.

I.

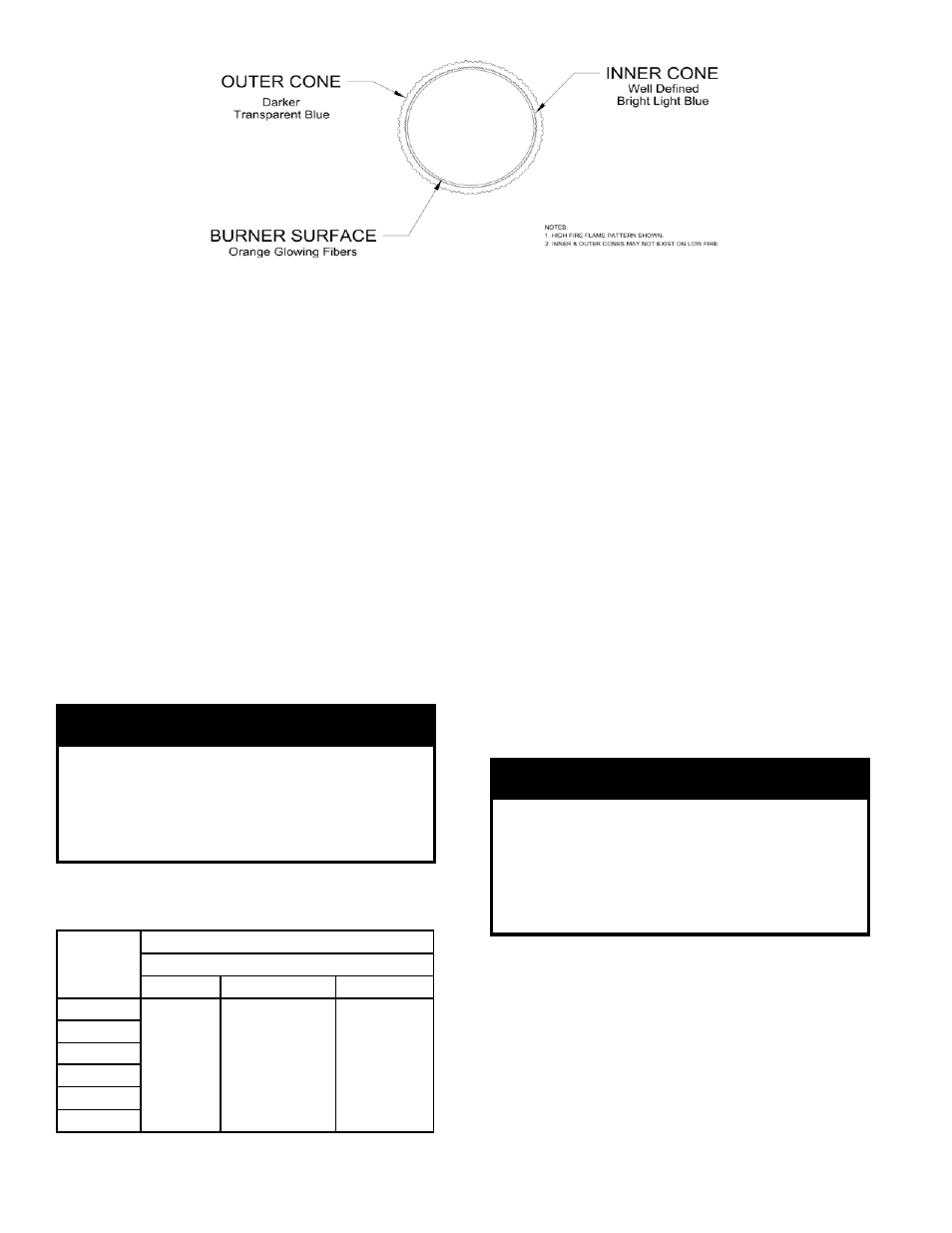

Check Burner Flame

Inspect the flame visible through the window. On high

fire the flame should be stable and mostly blue (Figure

47). No yellow tipping should be present; however,

intermittent flecks of yellow and orange in the flame are

normal.

J.

Check Gas Inlet Pressure

Check the inlet pressure and adjust if necessary. Verify

that the inlet pressure is between the upper and lower

limits shown on the rating plate with all gas appliances

on and off.

WaRning

The outlet pressure for the gas valve has been

factory set and requires no field adjustment. This

setting is satisfactory for both natural gas and

propane. attempting to adjust the outlet pressure

may result in damage to the gas valve and cause

property damage, personal injury or loss of life.

K.

Perform Combustion Test

Perform a combustion test. Boilers equipped with a

concentric vent system have a flue gas sample tap

located in the boiler vent collar (under the screw cap).

Insert the analyzer probe in the flue gas sample tap.

Check CO

2

(or O

2

) and CO at both high and low fire.

The boiler may be temporarily locked into high or low

fire for 15 minutes as follows:

1. To lock the boiler in high fire, simultaneously press

and hold the “Mode” button and “+“ button until the

display flashes “H”, indicating that the boiler has

been driven to high fire. After this happens, allow

the boiler to operate for approximately 5 minutes

before taking combustion readings.

2. To lock the boiler in low fire, simultaneously press

and hold the “Mode” button and “-“ button until the

display flashes “L”, indicating that the boiler has

been driven to low fire. After this happens, allow the

boiler to operate for approximately 5 minutes before

taking combustion readings.

3. Normal modulation of the boiler should return 15

minutes after the boiler is locked in high or low fire.

Typical CO

2

readings are shown in Table 20.

WaRning

Each alpine Series boiler is tested at the factory

and adjustments to the air fuel mixture are

normally not necessary. Consult a U.S. Boiler

representative before attempting to make any

such adjustments. improper gas valve or mixture

adjustments could result in property damage,

personal injury, or loss of life.

Boiler

Model

Altitude Range

0 - 7000 Ft.

% CO

2

% O

2

Range

CO, PPM

ALP080

8.2 - 8.8

5.5 - 6.5

Less than 75

PPM

ALP105

ALP150

ALP210

ALP285

ALP399

Table 20: Recommended Combustion Settings,

natural gas

Figure : Burner Flame

L.

Test External Limits

Test any external limits or other controls in accordance

with the manufacturer’s instructions.

M.

Check Thermostat Operation

Verify that the boiler starts and stops in response to

calls for heat from the heating thermostat and indirect

water heater thermostat. Make sure that the appropriate

circulators also start and stop in response to the

thermostats.