Burnham ALP150 User Manual

Page 13

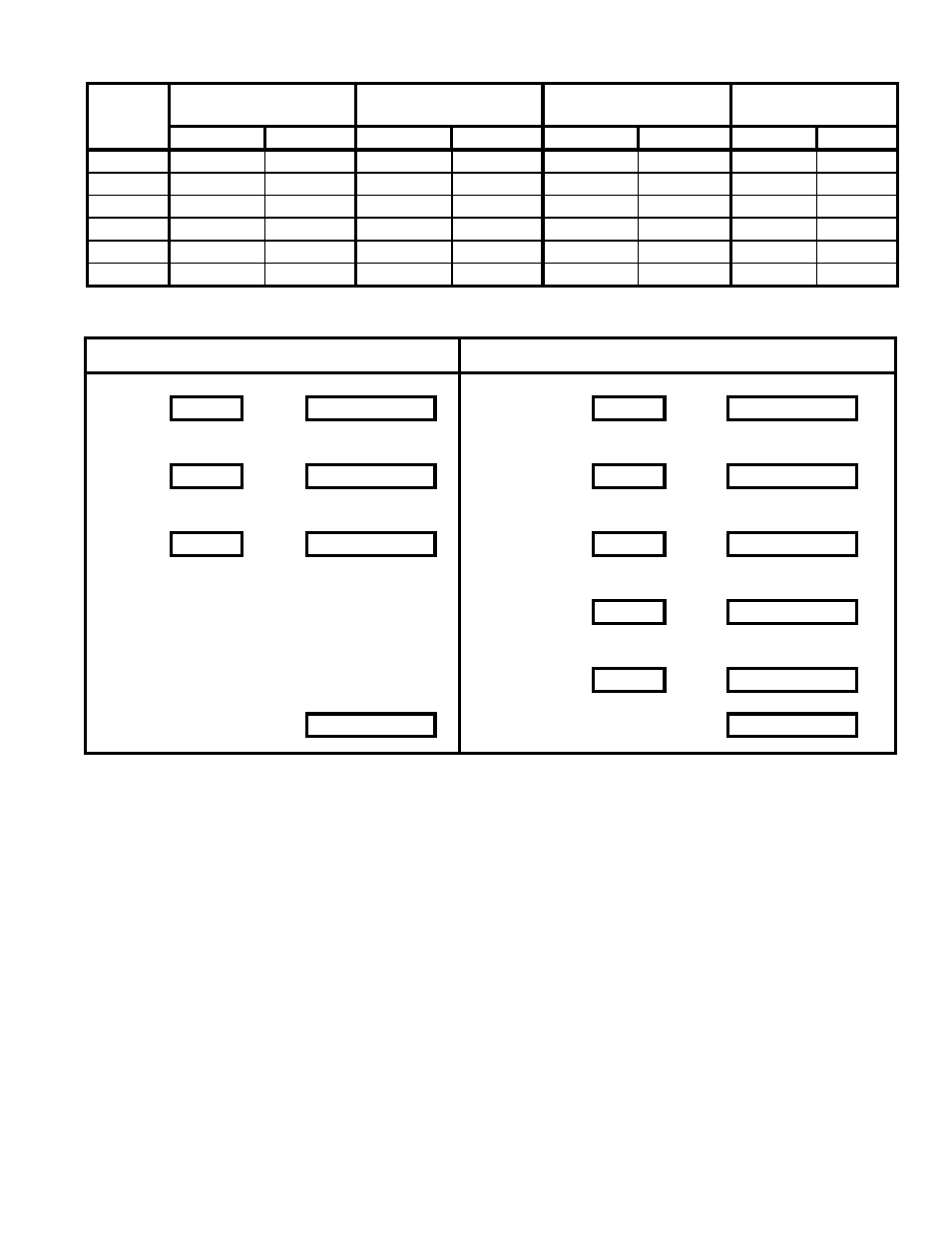

1

Boiler

Model

3” Combustion Air Pipe

(Equivalent Length)

4” Combustion Air Pipe

(Equivalent Length)

3” Vent Pipe

(Equivalent Length)

4” Vent Pipe

(Equivalent Length)

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

ALP080

21-7/8 In.

60 Ft.

---

---

21-7/8 In.

60 Ft.

---

---

ALP105

21-7/8 In.

60 Ft.

---

---

21-7/8 In.

60 Ft.

---

---

ALP150

---

---

21-7/8 In.

60 Ft.

21-7/8 In.

60 Ft.

---

---

ALP210

---

---

21-7/8 In.

60 Ft.

21-7/8 In.

60 Ft.

---

---

ALP285

---

---

32 In.

60 Ft.

---

---

32 In.

60 Ft.

ALP399

---

---

32 In.

60 Ft.

---

---

32 In.

60 Ft.

Table : Vent/Combustion air Pipe Length

Combustion air

Vent

90° elbow(s) PVC

Supplied 30” straight CPVC

Quantity =

x 5’ =

equiv. ft. a.

Length ft. =

2.5

x 1 =

2.5 equiv. ft. a.

45° elbow(s) PVC

Supplied 90° elbow CPVC

Quantity =

x 2.5’ =

equiv. ft. b.

Quantity =

1

x 5’ =

5 equiv. ft. b.

Straight pipe PVC

90° elbow(s) PVC

Length ft. =

x 1 =

equiv. ft. c.

Quantity =

x 5’ =

equiv. ft. c.

45° elbow(s) PVC

Quantity =

x 2.5’ =

equiv. ft. d.

Straight pipe PVC

Length ft. =

x 1 =

equiv. ft. e.

Total*

a.+b.+c. =

equiv. ft.

Total*

a.+b.+c.+d.+e.=

equiv. ft.

* Total cannot exceed 60 equiv. ft. length.

Vent and combustion air terminals do not count towards total equiv. ft.

Combustion Air/Vent, Equivalent Length Work Sheet

This sheet is supplied to assist in vent/combustion air, equivalent length calculating

Note: For one or two family dwellings, fire

resistance rating requirement may not need to be

met, but is recommended.

7. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

at rear of boiler and work towards vent termination.

8. Design the Vent System to allow a 3/8” of thermal

expansion per 10 feet of CPVC/PVC pipe. Runs of

20 ft. or longer that are restrained at both ends must

use an offset or expansion loop. Refer to Figure 3.

9. Follow all manufacturer instructions and warnings

when preparing pipe ends for joining and using the

primer and the cement.

D.

Installation of Two-Pipe CPVC/PVC Gas Vent/

Combustion Air System Connector

The boiler two pipe vent system connector for CPVC/

PVC and gasket are shipped inside the vent carton. The

vent connector mounting hardware - six (6) #8 x ½”

black oxide round head Phillips sheet metal screws - are

shipped inside Miscellaneous Part Carton.

1. Remove the vent connector and gasket from the vent

carton.

2. Locate six mounting screws.

3. Position the vent connector and gasket onto jacket

combination rear/bottom panel and insert vent

connector inner stainless steel vent pipe into the heat

exchanger vent outlet.

4. Align vent connector plate and gasket clearance

holes with rear/bottom panel engagement holes; then

secure the collar and gasket to rear/bottom panel

with six mounting screws. See Figure 4.

5. Flue temperature sensor, factory attached to the

boiler wiring harness, is secured to the boiler rear/

bottom panel with tape.