Warning – Burnham ALP150 User Manual

Page 14

1

6. Remove the Silicone flue sensor cap from the vent

carton and press onto the two pipe vent system

connector for CPVC/PVC sensor port. Remove

the tape holding the flue sensor and insert the flue

temperature sensor into the flue sensor plug until it

is firmly engaged. See Figure 4.

7. Near-Boiler Vent Piping (see Figure 5):

WaRning

all CPVC vent components (supplied with boiler)

must be used for near-boiler vent piping before

transitioning to Schedule 0 PVC pipe (aSTM

2665) components for remainder of vent system.

a. All CPVC vent components (supplied with

boiler), 30” straight and 90° elbow, must be

used for near-boiler piping before transitioning

to Schedule 40 PVC (ASTM 2665) pipe

components for remainder of vent system.

The CPVC 30” straight section may be cut to

accommodate desired vent configuration for

near-boiler piping, provided both pieces are used

in conjunction with the CPVC 90° elbow, before

any PVC components are used. Ensure that the

CPVC elbow is the first elbow used in the vent

system as it exits the boiler.

b. Clean all vent and combustion air pipe joints

with primer and secure with transition cement,

(8 oz. bottle of primer and 8 oz. bottle of

transition cement supplied with boiler). Follow

the instructions provided on the primer and

cement.

E.

CPVC/PVC Horizontal Venting System

See Figures 3 thru 8.

Vent Piping - Horizontal

1. See Paragraph D for instructions on attaching the

vent system connector to the boiler.

2. Do not exceed maximum vent length. Refer to

Table 7 for pipe diameters and allowable lengths.

3. Horizontal vent pipe must maintain a minimum ¼

inch per foot slope down towards boiler.

4. Use appropriately designed thimbles when passing

through combustible walls (thimble use is optional

for noncombustible walls). Insert thimble through

wall from outside. Secure outside flange to wall

with nails or screws, and seal ID, OD and vent holes

with sealant material. Install inside flange to inside

wall, secure with nails or screws, and seal with

sealant material.

5. For noncombustible wall application when thimble

is not used, size opening such that a minimal

clearance is obtained.

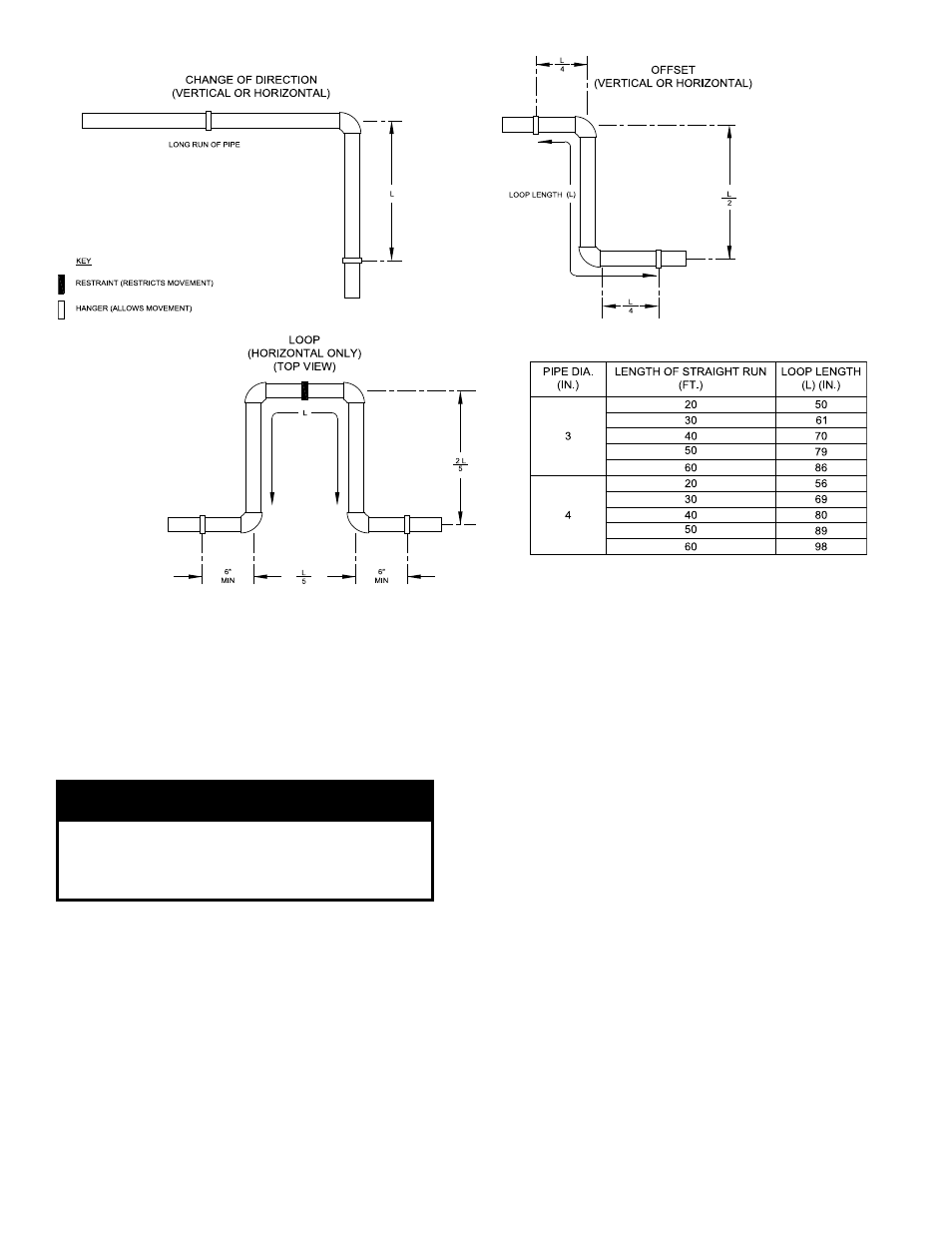

Figure : Expansion Loop and Offset