Lubricator overview, 1 general overview – Norgren Lubricators User Manual

Page 2

Lubricator Overview

Littleton, CO USA

Phone 303-794-2611

Fax 303-795-9487

ALE-14-B

1.1

GENERAL OVERVIEW

Norgren manufactures two main types of lubricators:

Oil-Fog and Micro-Fog. These units are mounted

directly into the pipe and add small amounts of oil

to the air flowing through them.

Oil Fog-Lubricators:

All the oil droplets seen in the sight dome are added

directly into the air flow. This results in relatively

large oil droplets passing downstream, suitable for

heavy lubrication applications eg single cylinders

and tools. Most competitive in line lubricators are

of the Oil-Fog type.

Micro-Fog Lubricators:

The oil droplets seen in the sight dome are atomized

and collected in the area above the oil in the bowl.

The smaller lighter particles are drawn into the air

flow and pass downstream.

As a result typically only 10% of the oil

seen as drops in the sight dome is passed

downstream. The remainder falls back into the oil

reservoir. Consequently, drip rate settings are

somewhat higher than their Oil-Fog equivalent. This

makes setting much easier, particularly in low flow

applications.

The fine Micro-Fog oil particles can travel

long distances through complex pipe work making

Micro-Fog lubricators suitable for multiple valve

and cylinder circuits.

1.2

WHAT ARE THE

DIFFERENCES BETWEEN

MICRO-FOG AND OIL-FOG?

1.2.1

Oil-Fog:

•

Large oil particles not as fine as micro-fog.

•

All oil drips seen in sight domes are

delivered downstream.

•

For applications over short distances.

•

Should be mounted at same level or higher

than device being lubricated.

•

Standard bowls can be filled under

pressure. (Not on rapid cycle units).

•

Suitable for heavy lubrication applications

eg single large cylinders and tools.

•

Has a flow sensor which provides constant

oil output density for varying flows.

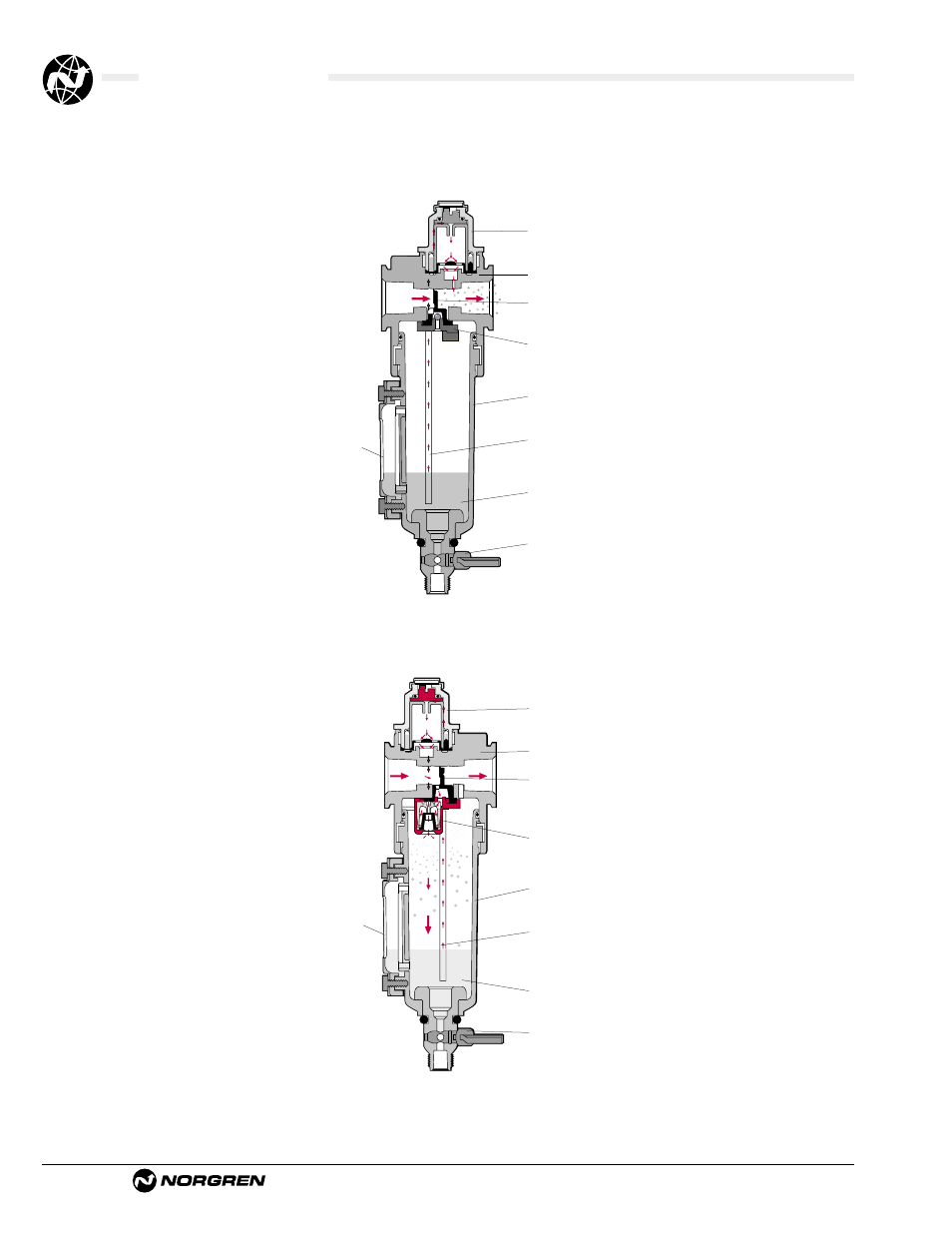

OIL-FOG LUBRICATOR

MICRO-FOG LUBRICATOR

Sight

dome

Body

Flow

sensor

Generator

assembly

Bowl

Syphon

tube

Oil

Drain

(optional)

Metal bowl

sight glass

Sight

dome

Body

Flow

sensor

Check

valve

Bowl

Syphon

tube

Oil

Drain

(optional)

Metal bowl

sight glass

1.2.2

Micro-Fog:

•

Small oil particles; less than 2 micron.

•

Only 10% of ‘drip rate’ is delivered

downstream as active lubricant (remainder

is returned to main oil reservoir).

•

High drip rates make drip setting easier in

low flow applications.

•

Can be mounted above or below the point

of application.

•

Cannot be filled without shutting off

upstream air (unless a quick fill cap or

remote fill device is used).

•

For use with lengthy air lines, multiple

valve and cylinder circuits.

•

Has a flow sensor to provide an almost

constant oil output density for varying

flows.

1.2.3

Can Oil-Fog and Micro-Fog Units be

Converted?

Generally not, simply changing a green (Oil-Fog)

sight dome for a red (Micro-Fog) sight dome does

not change the function.

Some lubricators are designed around a

cartridge insert. In this case it may be possible to

swap the cartridge and sight domes to change the

function.