Air-oil tank volumes (cubic inches), Rod alignment coupler, Air-oil tank – Norgren NFPA Aluminum & Steel Cylinders User Manual

Page 94: How to figure length of volume, Air-oil tank dimensions, Rod alignment coupler dimensions, Act-1-94, Available in 5 practical bore sizes: 1

ACT-1-94

Brookville, OH USA

Phone 937-833-4033

www.norgren.com

Series A, NFPA Aluminum Air Cylinders (ø1-1/2" to 8"), Cylinder Features

All Dimensions in Inches (mm)

(38.10)

(68.25)

(101.60)

(142.88)

(219.08)

(31.75)

(50.80)

(63.50)

(63.50)

(76.20)

(19.05)

(101.60)

(127.00)

(127.00)

(168.28)

(19.05)

(120.65)

(152.40)

(152.40)

(203.20)

(9.53)

(12.70)

(12.70)

(17.45)

(3.18)

(4.75)

(4.75)

(6.35)

(63.50)

(95.25)

(139.70)

(215.90)

(44.45)

(69.85)

(107.95)

(180.98)

(11.10)

(14.27)

(14.27)

(20.62)

(3.18)

(9.53)

(12.70)

(12.70)

(19.05)

(3.18)

(6.35)

(9.53)

(9.53)

(12.70)

1.500

2.687

4.000

5.625

8.625

1.250

2.000

2.500

2.500

3.000

.750

4.000

5.000

5.000

6.625

.750

4.750

6.000

6.000

8.000

.375

.500

.500

.687

.125

.187

.187

.250

2.500

3.750

5.500

8.500

1.750

2.750

4.250

7.125

.437

.562

.562

.812

.125

.375

.500

.500

.750

.125

.250

.375

.375

.500

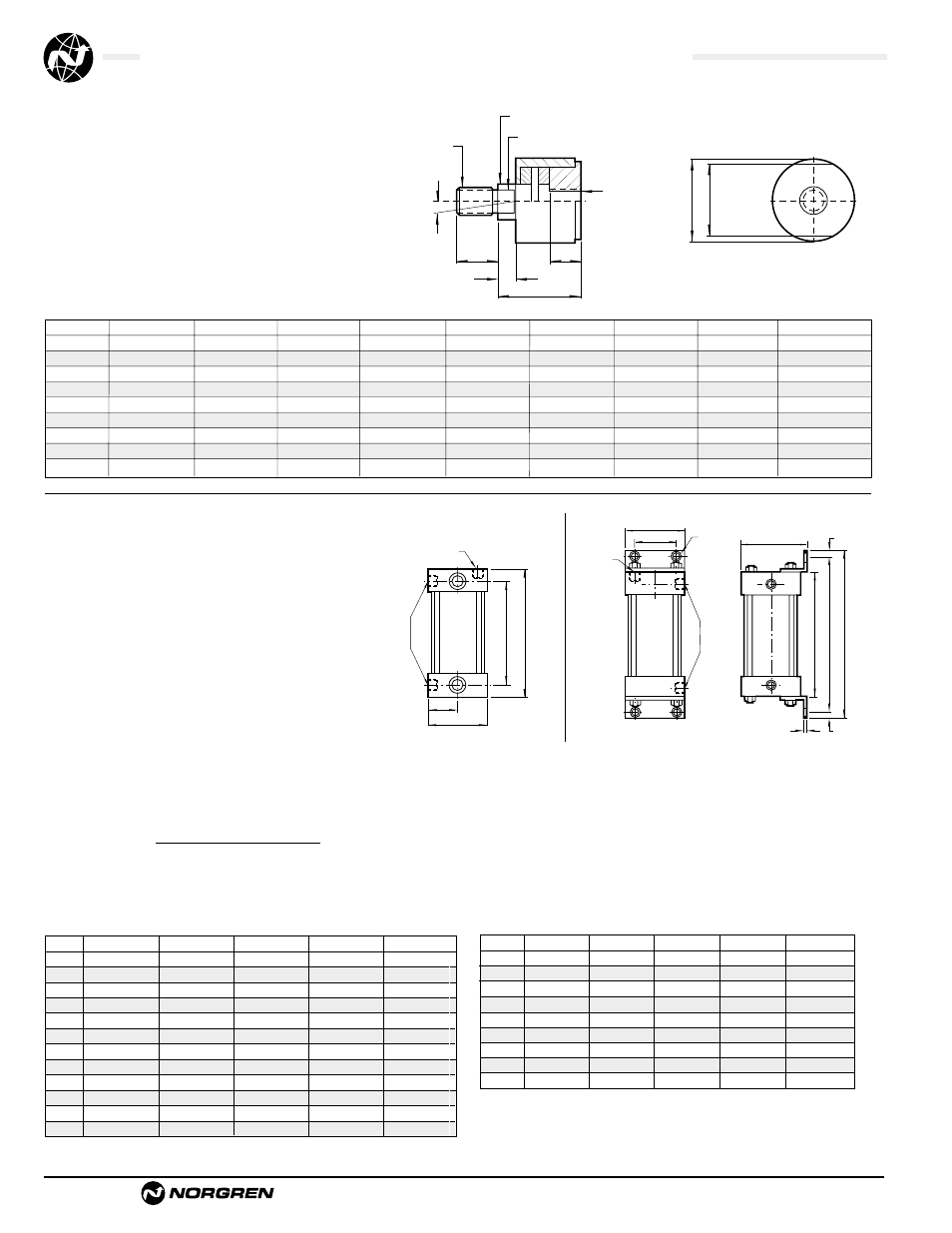

Air-Oil Tank Volumes (cubic inches)

G Across Flats

øF Shank

.062

Radial Float

2˚ Spherical

Motion

øB

A Thds.

A Thds.

E

E

D

C

H Across

Flats

Rod Alignment Coupler

The Rod Alignment Coupler allows 1/16" of radial

float and 2° of spherical movement. This prevents

cylinder binding due to misalignment thus

extending bearing and seal life, and permits

greater tolerance between the centerline of the

cylinder and mating part for simplified installation.

Air-Oil Tank

Available in 5 practical bore sizes: 1

1

/

8

", 2", 3

1

/

4

",

5", and 8", the Air-Oil Tank includes a translucent

fiberglass tube which permits viewing of the tank

oil level from any position, internal baffles that

reduce foaming and aeration of the system oil

resulting in maximum cylinder control, and

standard angle mounting brackets (except 1

1

/

8

"

bore) easily removed for convenient fluid

port positioning.

How to Figure Length of Volume

The following equations are given to help you in selecting the right air/oil tank volume for your particular application.

Volume of Cylinder: • Cap End

Cylinder Bore Area x Stroke = Volume

• Head End

Cylinder Bore Area – (Piston Rod Area*) x Stroke = Volume *

Reference Page ACT-1-13 for Areas.

Length of Tank = Volume of Cylinder x 1.3** (See chart below.)

**30% minimum recommended reserve working volume.

Tank Bore Area

Final Length of Volume of Tank = Working length of tank + 2" minimum safety factor to prevent aeration of oil.

Note: Length must be at least 3".

øJ (4)

L NPT

Fill Port

K NPT

Port

*C *B

D

A

K NPT

Port

G

H

L NPT

Fill

Port

F

E

*D

*C

*B

E

A

1 1/8" Bore only

*plus internal length

.995 sq."

3.14 sq."

8.30 sq."

19.64 sq."

50.26 sq."

5.9

18.6

49.8

117.8

301.5

7.9

25.1

66.4

157.1

402.0

9.9

31.4

83.0

196.4

502.6

11.9

37.6

99.6

235.6

603.1

13.9

43.9

116.2

274.9

703.6

15.9

50.2

132.8

314.2

804.1

17.9

56.5

149.4

353.5

904.5

19.9

62.8

166.0

392.8

1005.2

Bore

1-1/8"

2"

3-1/4"

5"

8"

Area

6"

8"

10"

12"

14"

16"

18"

20"

Internal Length of Tank

Air-Oil Tank Dimensions

How to Order: Specify air-oil tank part number and internal length.

Example: 2" bore with 6" internal length = AOT-04 x 6

Note: Maximum operating pressure 250 PSI.

Bore

1-1/8"

2"

3-1/4"

5"

8"

AOT-225

AOT-04

AOT-065

AOT-10

AOT-16

A

B

C

D

E

–

F

–

G

–

H

–

øJ

–

K

L

(31.75)

(31.75)

(31.75)

(44.45)

(44.45)

(63.50)

(63.50)

(82.50)

(82.50)

(50.80)

(50.80)

(50.80)

(58.72)

(58.72)

(74.60)

(74.60)

(111.13)

(111.13)

(12.70)

(12.70)

(12.70)

(12.70)

(12.70)

(12.70)

(12.70)

(20.62)

(20.62)

(19.05)

(19.05)

(19.05)

(28.58)

(28.58)

(41.28)

(41.28)

(57.15)

(57.15)

(28.58)

(28.58)

(28.58)

(24.61)

(24.61)

(34.93)

(34.93)

(44.45)

(44.45)

(12.70)

(12.70)

(12.70)

(20.62)

(20.62)

(29.36)

(29.36)

(38.10)

(38.10)

(28.58)

(28.58)

(28.58)

(38.10)

(38.10)

(57.15)

(57.15)

(76.20)

(76.20)

1.250

1.250

1.250

1.750

1.750

2.500

2.500

3.250

3.250

2.000

2.000

2.000

2.312

2.312

2.937

2.937

4.375

4.375

.500

.500

.500

.500

.500

.500

.500

.812

.812

.750

.750

.750

1.125

1.125

1.625

1.625

2.250

2.250

.625

.625

.625

.969

.969

1.375

1.375

1.750

1.750

.500

.500

.500

.812

.812

1.156

1.156

1.500

1.500

1.125

1.125

1.125

1.500

1.500

2.250

2.250

3.000

3.000

Rod Alignment Coupler Dimensions

CC-1-07

CC-1-08

CC-1-10

CC-1-12

CC-1-14

CC-1-16

CC-1-20

CC-1-24

CC-1-28

A

7/16 – 20

1/2 – 20

5/8 – 18

3/4 – 16

7/8 – 14

1 – 14

1

1

/

4

– 12

1

1

/

2

– 12

1

3

/

4

– 12

B

C

D

E

F

G

H

Max Pull (lbs.)

10,000

14,000

19,000

34,000

39,000

64,000

78,000

134,000

134,000