Cylinder order information, Act-1-78 – Norgren NFPA Aluminum & Steel Cylinders User Manual

Page 78

ACT-1-78

Brookville, OH USA

Phone 937-833-4033

www.norgren.com

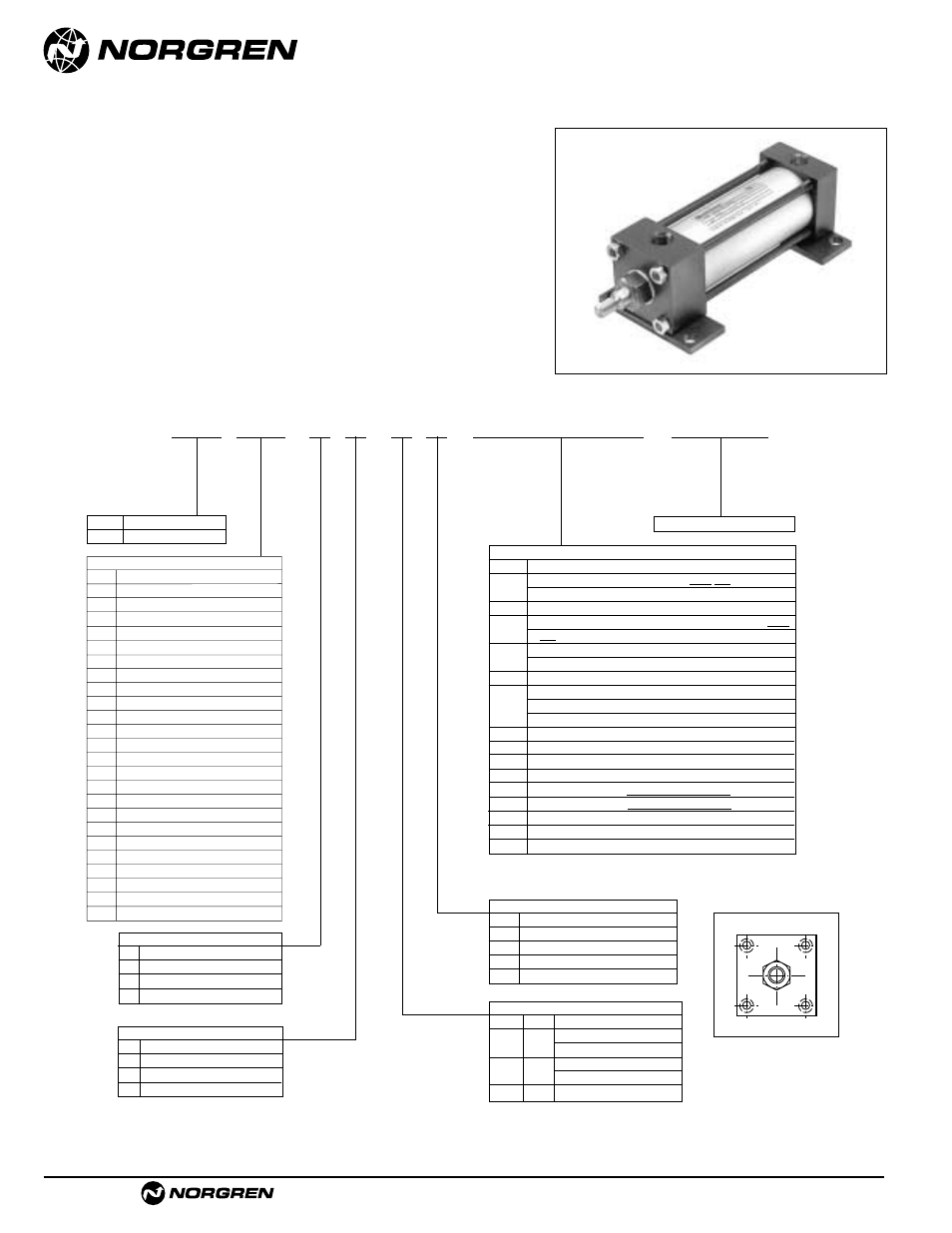

Series A & EA Aluminum Air Cylinders (ø1-1/2 to 6")

● 60 Base (Not NFPA) Bar Mount

for 1-1/2" to 6" bore sizes.

● Series A Cylinders rated to 250 PSI air,

400 PSI hydraulic (non-shock).

Series EA Cylinders rated to 250 PSI air only.

● Designed for non-lube service.

● Switches available on all bore sizes.

(See pages ACT-1-90 & 91 for ordering information.)

Cylinder with 60 (Not NFPA) Base Bar

See page ACT-1-96 for complete instructions on how to order cylinders.

Additional Options – order alphabetically – More on page ACT-1-95.

HR

Case Hardened (45 Rc)

L(_ _) Port Location position 1 standard: L(Head Cap)

(specify position 1 thru 4 for head and/or cap)

MS

Metal Rod Scraper

N(_ _) Cushion Adjust Screw Location position 2 standard: N(Head

Cap) (specify position 1 thru 4 for head and/or cap)

P(_)*

Non-Standard Port Sizes: [specify port size for P(_H) head

only, P(_C) cap only, or P(_) both head & cap]

PS Magnetic

Piston

RS

Rod Stud

Type 1 (5/8" – 1

3

/

4

" øRod)

Type 2 (5/8" & 1" øRod)

RX

Rod Extensions (specify length of additional rod extension)

SC

Single Acting Spring Extend (Cap End)–See page ACT-1-86

SR

Single Acting Spring Retract (Rod End)–See page ACT-1-86

SS

303 Stainless Steel (Hard Chrome Plated)

ST(_C) Stop Tube (Cap End) (specify stop tube length)

ST(_R) Stop Tube (Rod End) (specify stop tube length)

T

Special Rod Threads (specify rod thread)

TX

Thread Extensions (specify length of thread extension)

V Viton

®

Seals

*1

1

/

2

", 2", 2

1

/

2

" bore cylinders have

3

/

8

" NPT Standard,

1

/

2

" NPT oversize.

3

1

/

4

", 4", 5" bore cylinders have

1

/

2

" NPT Standard,

3

/

4

" NPT oversize.

This will add

1

/

8

" to the overall cylinder length.

Mounting Options

01

Side Tapped (MS4)

03

Head Rectangular Flange (MF1)

03

Head Square (ME3) – 7" & 8" Bores

04

Cap Rectangular Flange (MF2)

04

Cap Square (ME4) – 7" & 8" Bores

05

Basic Cylinder No Mounting (MX0)

06

Both Ends (4) Tie Rods Ext. (MX1)

6B

Both Ends (2) Tie Rods Ext. (MX4)

6C

Cap Tie Rods Ext. (MX2)

6R

Head Tie Rods Ext. (MX3)

7R

Head Trunnion (MT1)

8R Cap Trunnion (MT2)

09

Side Lugs (MS2)

10

Center Trunnion (MT4)

11

Side End Angles (MS1)

12

Cap Fixed Clevis (MP1)

15

Side End Lugs (MS7)

16

Sleeve Nut Construction (Universal)

20

Head Square Flange (MF5)

21

Cap Square Flange (MF6)

22

Detachable Cap Clevis (MP2)

32

Cap Fixed Eye (MP3)

42

Detachable Cap Eye (MP4)

52

Spherical Bearing

60

Base Bar (Not NFPA)

A

Series A Cylinder

EA

Series EA Cylinder

Cylinder Order Information

60

–

–

–

–

Bore and Stroke (write out )

Piston Rod Diameters

A

5

/

8

"

Standard on 1

1

/

2

", 2", 2

1

/

2

"

Standard on 3

1

/

4

", 4", 5"

B

1"

Oversized on 1

1

/

2

", 2", 2

1

/

2

"

Standard on 6", 7", 8"

C

1

3

/

8

"

Oversized on 3

1

/

4

", 4", 5"

D

1

3

/

4

" Oversized on 6", 7", 8"

1

3

4

2

Piston Rod Threads Type

1

Small Male (Solid)

2

Intermediate Thread Male (Solid)

3

Female

6

Full Thread Male (Solid)

7

Plain Rod End

Port and Cushion Adjustment

Positions

(As viewed from rod end:

Port standard position 1, Cushion

Adjustment standard position 2.)

NOTE: A Port and a Cushion Adjustment

cannot be in the same position.

†

Standard with EA

†

Standard with EA

Cushion in Head

3

None

5

†

Non-Adjustable Cushion

7

Adjustable Cushion (Position 2)

9

Decel Cushion

Cushion in Cap

3

None

5

†

Non-Adjustable Cushion

7

Adjustable Cushion (Position 2)

9

Decel Cushion