Norgren NFPA Aluminum & Steel Cylinders User Manual

Page 14

ACT-1-14

Brookville, OH USA

Phone 937-833-4033

www.norgren.com

Series A & EA, NFPA Aluminum Air Cylinders, Technical Information

Series J & EJ, NFPA Steel Air Cylinders, Technical Information

Piston Rod Diameter Selection:

Applications requiring long extend (push) strokes may require

oversize piston rod diameters to prevent buckling.

To determine the correct rod diameter for your application

follow these simple steps:

1. Select the thrust from the Cylinder Force and Volume Chart

(page ACT-1-13) that is required for your application.

Thrust = Piston Surface Area x Operating Pressure

2. From the Cylinder Mounting Diagram Chart

(page ACT-1-15) select the mounting style being used.

3. With the piston rod fully extended, calculate the value of L (in

inches). Multiply cylinder stroke by appropriate stroke factor

located in Cylinder Mounting Diagram Chart to obtain

effective length L.

4. Locate the value of L (in inches) from the Determining

Adequate Rod Diameter Chart.

5. Selecting Stop Tubes: Stop tubes enhance the transverse load

carrying capability of a long stroke cylinder by increasing the distance

between the piston and rod bearing at full extension (Refer to page

ACT-1-87). When the value of L (calculated from the Adequate Rod

Diameter Chart) is less than 40", a stop tube is not required.

However, if L is 40" or more, 1" of stop tube is recommended for every

10" (or fraction thereof) over 40".

6. Recommended Mounting Styles for Maximum Stroke and

Thrust Load:

• Multiply cylinder stroke by appropriate stroke factor to obtain

effective length L.

• If cylinder has extra rod extension, add this extension to the stroke

length before obtaining effective length.

Tie Rod Tightening:

In order to reduce the possibility of cylinder binding or damage,

tighten to quarter unit increments of the final torque value in the

following order: #1, #2, #3, #4.

Then torque fully to the recommended foot pounds in the same order.

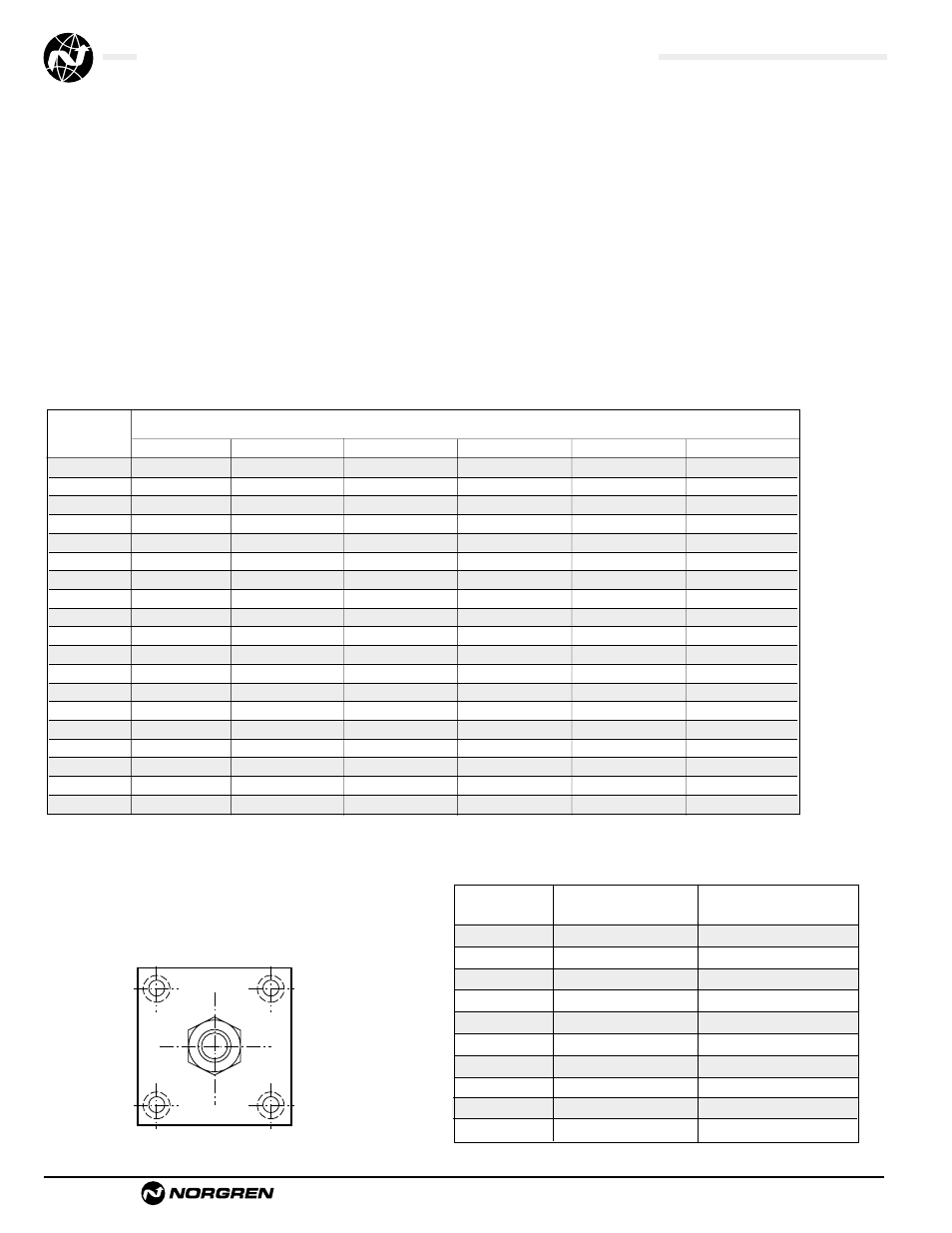

Determining Adequate Rod Diameter Chart

Note: In some cases it may be necessary to use a larger bore cylinder than is required

for force in order to obtain an adequate rod diameter.

1

3

4

2

Recommended Torques for Tightening Tie Rods

Extended

Maximum effective length “L”

Force

recommended for rod diameters

(lbs)

5/8"

1"

1-3/8"

1-3/4"

2"

2-1/2"

50

95

–

–

–

–

–

100

65

170

–

–

–

–

150

50

135

260

–

–

–

200

43

115

220

–

–

–

300

34

93

180

300

–

–

500

25

70

135

250

–

–

750

20

56

110

185

250

–

1000

17

48

94

160

220

–

1500

13

38

80

130

170

260

2000

11

33

64

110

140

225

3000

9

26

51

90

115

180

4000

7

22

44

75

100

155

5000

–

20

39

66

88

140

6000

–

18

35

60

79

125

8000

–

15

30

52

68

110

10000

–

12

26

46

60

95

12500

–

10

22

41

52

86

15000

–

–

19

37

48

79

20000

–

–

14

29

41

68

Cylinder

Standard

Stainless Steel

Bore

Steel Tie Rods

Tie Rods

1-1/2"

6.6 ft. lbs.

3.75 ft. lbs.

2"

11 ft. lbs.

7.5 ft. lbs.

2-1/2"

13 ft. lbs.

7.5 ft. lbs.

3-1/4"

20 ft. lbs.

13-14 ft. lbs.

4"

24 ft. lbs.

13-14 ft. lbs.

5"

40 ft. lbs.

33 ft. lbs.

6"

48 ft. lbs.

33 ft. lbs.

7" & 8"

100 ft. lbs.

65 ft. lbs.

10"

150 ft. lbs.

75 ft. lbs.

12"

175 ft. lbs.

87.5 ft. lbs.