Norgren ecology cylinders offer these advantages, Operates quietly to meet osha specifications, Summary of sound levels in decibels – Norgren NFPA Aluminum & Steel Cylinders User Manual

Page 8: Act-1-8

ACT-1-8

Brookville, OH USA

Phone 937-833-4033

www.norgren.com

Series J & EJ, NFPA Steel Air Cylinders, Impact Dampening Seals

PSI

Cylinder Bore

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

7

8

10

12

0

.14

.15

.17

.19

.22

.25

.28

.32

.32

.36

.40

20

.10

.10

.12

.14

.16

.18

.20

.22

.22

.24

.26

40

.07

.07

.08

.09

.10

.12

.13

.14

.14

.15

.16

60

.04

.04

.05

.05

.06

.07

.07

.08

.08

.09

.10

80

.02

.02

.02

.02

.03

.03

.03

.04

.04

.04

.04

100

0

0

0

0

0

0

0

0

0

0

0

In/Sec

Cylinder Bore

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

7

8

10

12

6

155.6

275.5

499.8

969.3

1505.4

2603.2

4159.8

5794.2

8067.6

12,242

20,139

12

38.4

68.1

123.4

239.7

372.6

644.8

1030.2

1435.8

2000.4

3026

4971

18

16.7

29.7

53.7

104.6

162.8

282.1

450.6

628.7

876.8

1319.3

2162.1

24

9.2

16.3

29.4

57.3

89.4

155.2

247.8

346.2

483.6

722

1179

30

5.6

10.0

18.1

35.4

55.4

96.4

153.9

215.4

301.6

445.5

724

36

3.7

6.7

11.9

23.5

37.0

64.5

102.9

144.4

202.7

295.3

476.8

42

2.6

4.6

8.2

16.3

25.8

45.3

72.2

101.6

143.1

204.8

327.7

48

1.8

3.2

5.8

11.7

18.6

32.8

52.2

73.8

104.4

146

231

54

1.3

2.4

4.2

8.5

13.6

24.2

38.5

54.7

77.9

105.7

164.7

60

1.0

1.8

3.0

6.2

10.1

18.1

28.7

41.1

58.9

76.9

117.2

Energy Absorption

Capacity of the Impact

Dampening Seals

The impact-dampening

Piston Seals in the Series EJ cylinder

allow for guaranteed, repeatable cushioning.

The compressive qualities of the piston seals are

predictable. The degree of seal compression at

various supply pressures is documented. (See

Energy Absorption Chart.) This allows you to

compute the exact cylinder size required by

knowing the weight (pounds) you are stopping

at a given speed.

Series EJ cylinders have a impact dampening

piston seal that accomplishes 80% of the actual

load stopping. The air cushion accounts for only

20%. (A conventional air cushioning cylinder

depends 100% on the compressibility

of air to do the stopping.) The EJ seal absorbs

high impact loads allowing the effect of the air

cushion

to be reduced by using a larger air cushion bleed

orifice. As a result the piston can move at a faster

speed for a longer period of time before the EJ

seal does the final stopping. See illustration at top

of ACT-1-9 for cushion operation.

3

Norgren Ecology Cylinders offer these advantages:

Norgren Guarantees

Non-lubricated Operation

for a Full Year!

The piston rod is self-lubricated by the

oil-impregnated rod bearing during operation.

Lubrication between piston and cylinder barrel

is derived from the polishing qualities of the

reinforced Teflon

®

wear ring.

The low friction surfaces extend the life of the

seals beyond normal expectations, permitting

Norgren to unconditionally guarantee non-

lubricated operation for one full year.

See page ACT-1-98 for complete warranty.

Series EJ cylinders are NFPA interchangeable

and are available in many different mounting styles.

Operates Quietly

to Meet

OSHA Specifications.

Series EJ cylinders provide substantial reductions in

impact noise, which reduces overall machine noise

and helps meet government regulations.

The summary of sound decibels chart illustrates the

operating sound levels.

The impact dampening qualities of the

Piston Seals are guaranteed for ONE FULL YEAR!

1

2

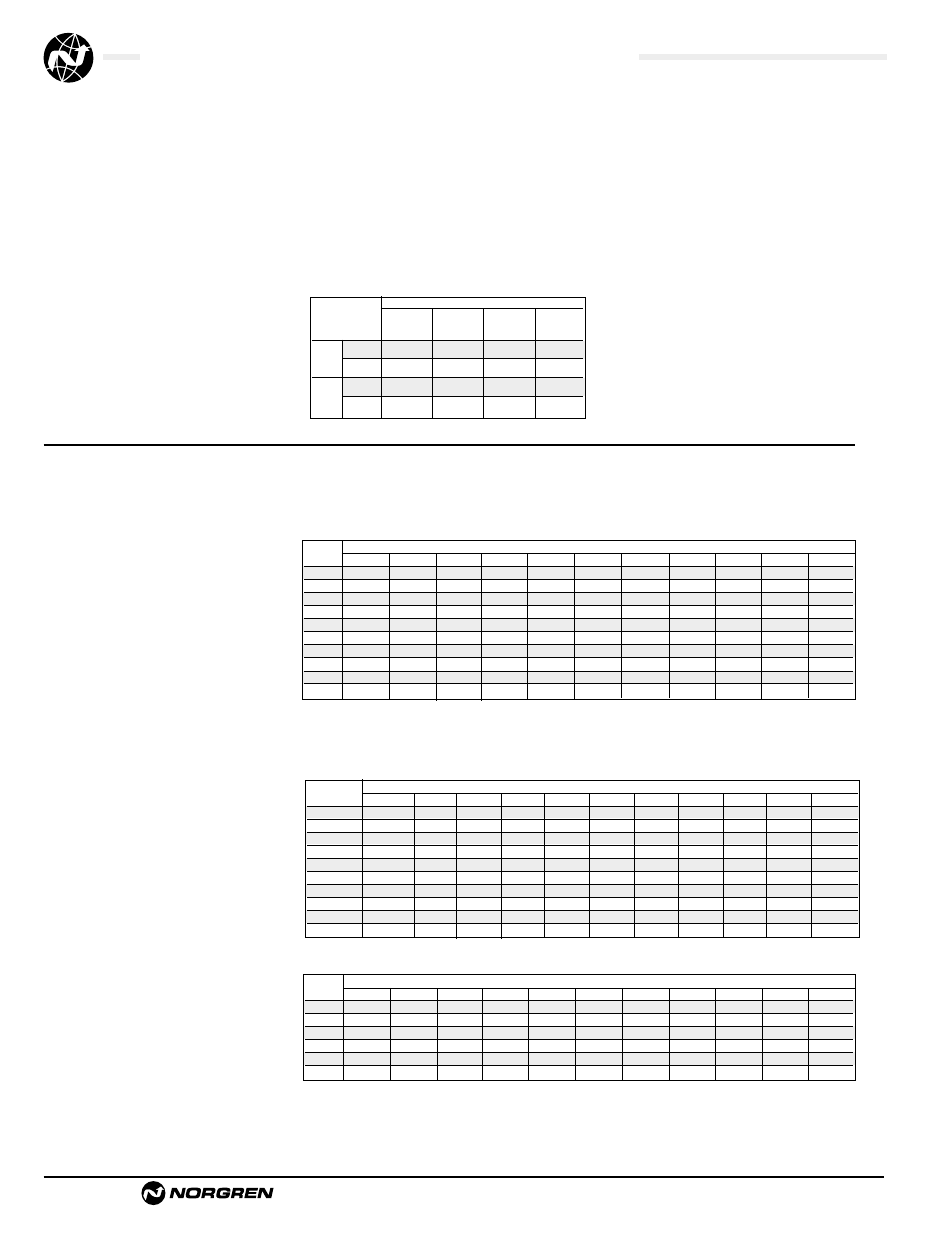

Summary of Sound Levels in Decibels

+ Peak sound pressure is given in decibels (dB)

re:2 x 10

5

N/m

2

.

++End position of mike was 3' on centerline from end of

cylinder; side position of mike was 3' perpendicular to

centerline abeam of end of cylinder.

Note: At 5 feet, cylinder sound levels would be less by 9 dB

from side figure and 13 dB from end figure. The total noise

emitted will depend on the structure to which the cylinder is

attached. If it is mounted on a thin flat plate of considerable

area, the noise will be increased by a sounding board effect.

Effect of Impact Dampening Seals on Total Stroke of Cylinders

*The weight of the cylinder piston has been deducted from the figures shown above.

Note: The use of Viton

®

Seals limits the absorption of the impact dampening seals by 50%.

Energy Absorption Capacity of the Impact Dampening Seals

*Usable Pounds Stoppable at the Following Piston Speeds

This chart features the energy absorption capacity of the impact dampening piston seals

with a Non-Adjustable cushions. For higher loads and velocities please refer to the Decel- Air

Cushion option on ACT-1-10.

Note: These figures are for new cylinders. The impact dampening seals will take some compression set during operation

of the cylinder and the stroke loss will decrease. Also, the pressure at zero stroke loss will decrease to about 80 psi.

At pressures above those of zero stroke loss, a slight clicking sound may be produced during impact.

To determine the stroke loss for either the head or cap end, divide the value shown by 2.

PSI Air Sound

Cylinder Model

Pressure

J133B3

EJ155B3

J1133A3

EJ1155A3

Level+

5" x 6"

5" x 6"

2" x 6"

2" x 6"

95

End++

108

73

110

74

PSI+

Side++

112

84

110

81

50

End++

108

73

113

74

PSI+

Side++

113

85

110

81

In/Sec

Cylinder Bore

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

7

8

10

12

6

279

495

899

1,744

2,709

4,685

7,486

10,429

4,520

22,035

36,250

12

68

122

221

430

699

1,159

1,854

2,583

3,800

5,446

8,947

18

30

53

95

187

291

507

810

1,130

1,576

2,374

3,891

24

16

29

52

102

160

279

444

622

869

1,299

1,414

30

10

18

32

63

99

172

275

387

541

801

1,303

36

6.7

12

21.6

42

66

116

183

259

363

531

856

42

4.7

8.3

14.7

29

46

81

129

181

257

367

588

48

3.4

5.7

10.4

21

33

59

93

131

187

262

415

54

2.3

4.3

7.6

15.3

24

43

68

97

138

189

295

60

1.8

3.2

5.4

11

18

33

52

74

106

138

211

Energy absorption capacity of the impact dampening

piston seals with an adjustable cushion.