3 design process, An379 – Cirrus Logic AN379 User Manual

Page 5

AN379

AN379REV2

5

3 Design Process

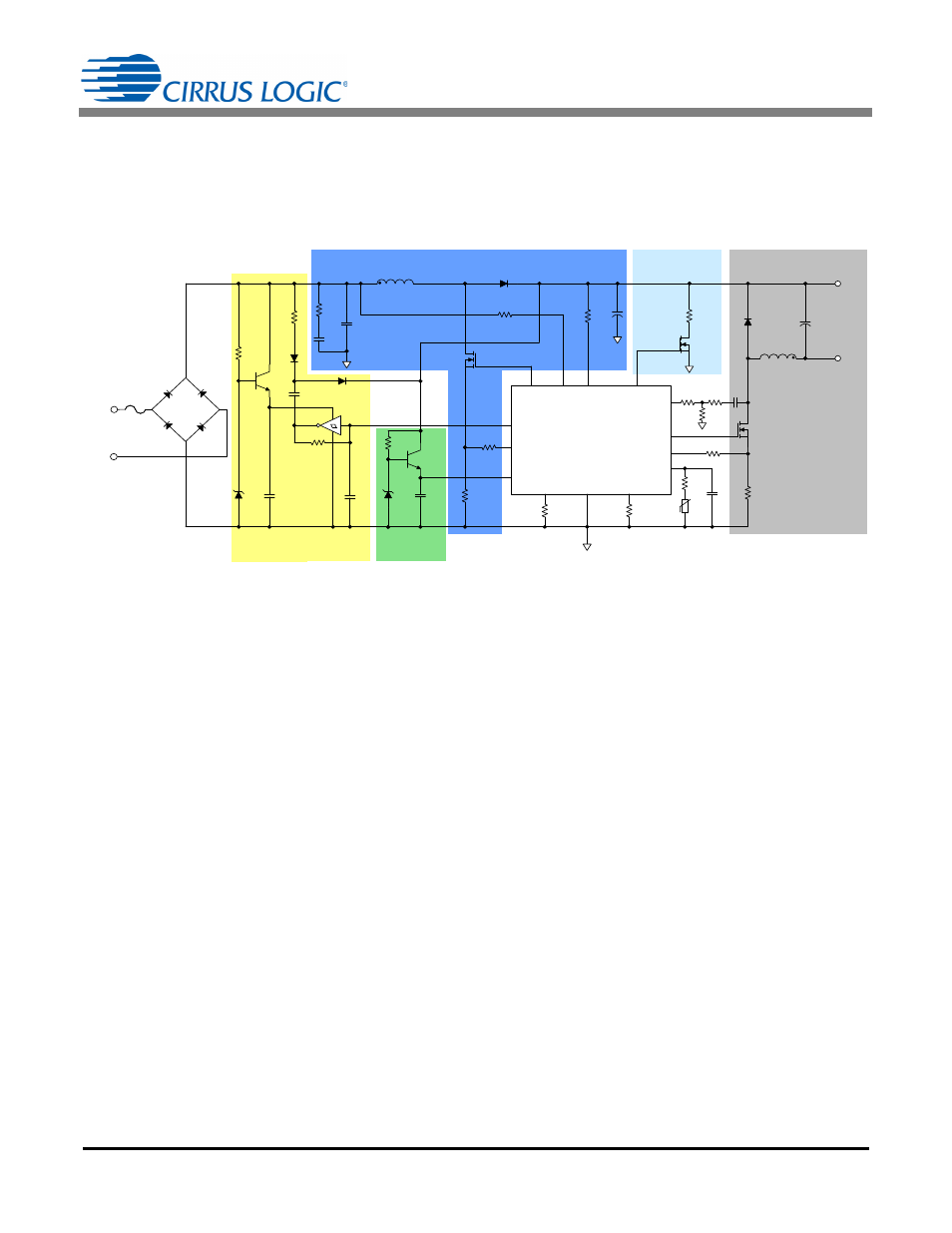

The design process for a two-stage power converter system can be partitioned into five circuit blocks (see Figure 1).

The AC line voltage is rectified, then converted to the desired DC output by a boost converter. The power converter

system includes the startup circuit, steady state supply, and active clamp support circuitry.

The CS1680 is a cascade boost-buck dimmable LED driver for the 12V halogen lamp-replacement market. The

CS1680 uses a Cirrus Logic proprietary intelligent digital control that provides exceptional single-lamp and

multi-lamp transformer compatibility for non-dimmer systems and dimmer systems paired with electronic and mag-

netic low-voltage transformers. An adaptive digital algorithm controls the boost stage and dimmer compatibility op-

eration mode to enable flicker-free operation to less than 10% output current with leading-edge and trailing-edge

dimmers. The rectified input voltage is sensed as a current into pin VAC and is used to control the adaptive trans-

former and dimmer compatibility algorithm and extract the phase of the input voltage for output dimming control.

The CS1680 integrates a continuous conduction mode (CCM) boost converter that provides transformer compati-

bility and dimmer compatibility. The output voltage of the CCM boost is sensed by the current into the boost output

voltage sense pin (BSTOUT). The buck stage is implemented with peak-current mode control. Voltage across an

external user-selected resistor is sensed through pin BUCKSENSE to control the peak current through the buck

stage inductor. Leading-edge and trailing-edge blanking on pin BUCKSENSE prevents false triggering.

The CS1680 voltage regulator is connected to an external startup circuit and steady state supply network. A startup

circuit provides a low-impedance path to improve electronic transformer compatibility. The GPIO pin is used to dis-

able the startup circuit when normal operation is reached. A linear regulator at the output of the boost converter pro-

vides steady-state operating current to the IC. During steady-state operation, the boost stage operates in continuous

conduction mode (CCM) to boost the input voltage. This operation allows the boost stage to provide transformer and

dimmer compatibility, reduces bulk capacitor ripple current, and provides a regulated input voltage to the buck stage.

LED+

LED-

C

OUT

NTC

D

B S T

Q

B UCK

9

12

2

13

R

CLA MP

R

S

C

NTC

R

B S T

V

rect

V

BST

D

B UCK

Q

CLA MP

C2

L

B S T

7

5

3

11

15

R

B UCK(S ense)

R

B S T(S ense)

Q

B S T

L

B UCK

R13

D7

1

16

R

CTRL1

R3

C21

R

CTRL2

4

6

14

Q4

D9

C4

R

rect

C9

R4

D11

U2

CS1680

BUCKGD

VAC

BUCKZCD

BSTGD

VDD

eOTP

BUCKSENSE

GND

CTRL1

CTRL2

CLAMP

GPIO

BSTSENSE

BSTOUT

C

B S T

Active Clamp

Buck

Boost

Startup Circuit

Steady State

Supply

BR 1

F1

12VAC/VDC

C

rect

D13

C5

Q5

R17

R26

R5

R6

R20

C12

R11

R12

Figure 1. Block Diagram of CS1680 Design