General description, 1 pfc operation, Cs1601 – Cirrus Logic CS1601H User Manual

Page 9

CS1601

DS931F3

9

5. GENERAL DESCRIPTION

The CS1601 offers numerous features, options, and

functional capabilities to the electronic product lighting

designer. This digital power factor correction (PFC) control IC

is designed to replace legacy analog PFC controllers with

minimal design effort.

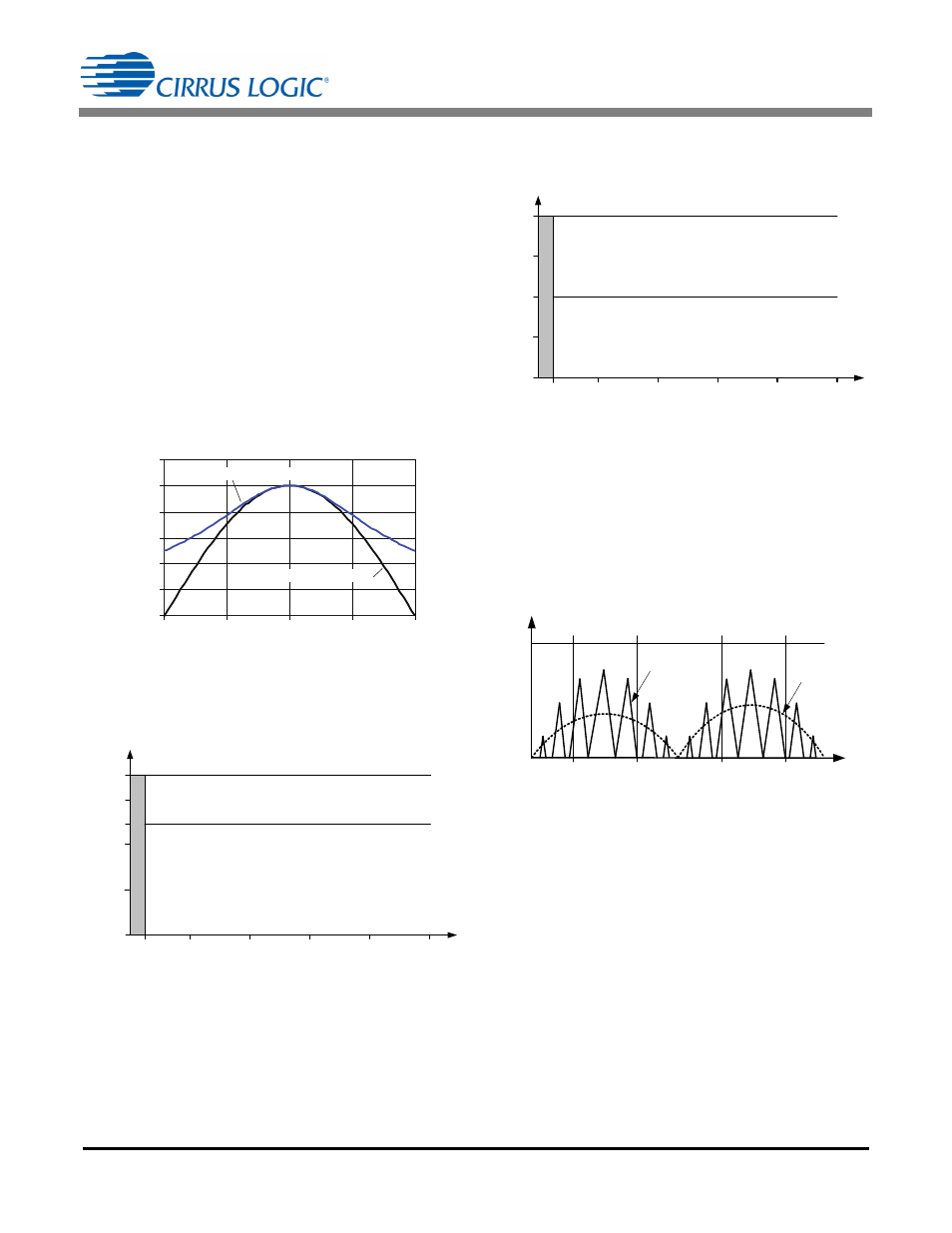

5.1 PFC Operation

One key feature of the CS1601 is its operating frequency

profile. Figure 10 illustrates how the frequency varies over a

half cycle of the line voltage in steady-state operation. When

power is first applied to the CS1601, it examines the line

voltage and adapts its operating frequency to the line voltage,

as shown in Figure 10. The operating frequency is varied from

the peak to the trough of the AC input. During startup, the

control algorithm generates maximum power while operating

in critical conduction mode (CRM), providing an approximate

square-wave current envelope within every half-line cycle.

Figure 10. Switching Frequency vs. Phase Angle

Figure 11 illustrates how the operating frequency of the

CS1601 (as a percentage of maximum frequency) changes

with output power and the peak of the line voltage.

Figure 11. CS1601 Max Switching Freq vs. Output Power

Figure 12 illustrates how the operating frequency of CS1601H

changes with output power and the peak of the line voltage.

Figure 12. CS1601H Max Switching Freq vs.Output Power

When P

O

falls below 5%, the CS1601 changes to Burst Mode.

on page 10 for more information.)

The CS1601 is designed to function as a DCM controller.

However, during peak periods, the controller may interchange

control methods and operate in a quasi-critical-conduction

mode (quasi-CRM) at low line. For example, at 108VAC main

input under full load, the PFC controller will function as a

quasi-CRM controller at the peak of the AC line cycle, as

shown in Figure 13.

Figure 13. DCM and Quasi-CRM Operation with CS1601

The zero-current detection (ZCD) of the boost inductor is

achieved using an auxiliary winding. When the stored energy

of the inductor is fully released to the output, the voltage on the

ZCD pin decreases, triggering a new switching cycle. This

quasi-resonant switching allows the active switch to be turned

on with near-zero inductor current, resulting in a nearly

lossless switch event. This minimizes turn-on losses and EMI

noise created by the switching cycle. PFC control is achieved

during light load by using on-time modulation.

0

20

40

60

80

100

120

0

45

90

135

180

Rectified Line Voltage Phase (Deg.)

% of Max

Switching Freq. (% of Max.)

Line Voltage (% of Max.)

% P

O max

F

SW

m

ax

(k

H

z)

20

70

60

40

40

5

Bu

rs

t M

od

e

20

0

60

80

100

48

Vin >156 VAC (Input Voltage 108 – 305 VAC, V

link

= 460V)

Vin <182 VAC (Input Voltage 108 –305 VAC , V

link

= 460V)

Vin <158 VAC (Input Voltage 90 –264 VAC, V

link

= 400 V)

Vin >136 VAC (Input Voltage 90 –264 VAC , V

link

= 400 V)

% P

O max

F

SW

m

a

x

(k

H

z)

100

75

Bu

rs

t M

od

e

25

0

50

Vin> 156 VAC (Input Voltage 108 –305 VAC , V

link

= 460V)

Vin< 182 VAC (Input Voltage 108 –305 VAC, V

link

= 460 V)

Vin< 158 VAC (Input Voltage 90– 264 VAC, V

link

= 400V)

Vin >136 VAC (Input Voltage 90 –264 VAC , V

link

= 400V)

20

40

5

60

80

100

DCM

Quasi CRM

DCM

Quasi CRM

DCM

I

LB

t [ms]

I

AC

In

du

ct

or

C

ur

re

n

t