WIKA CS4R User Manual

Page 16

Operating Instructions Temperature Indicating Controller CS4R

V1.2

•

05/2006

- 16 -

•

Setting range: 0 … 9999 seconds

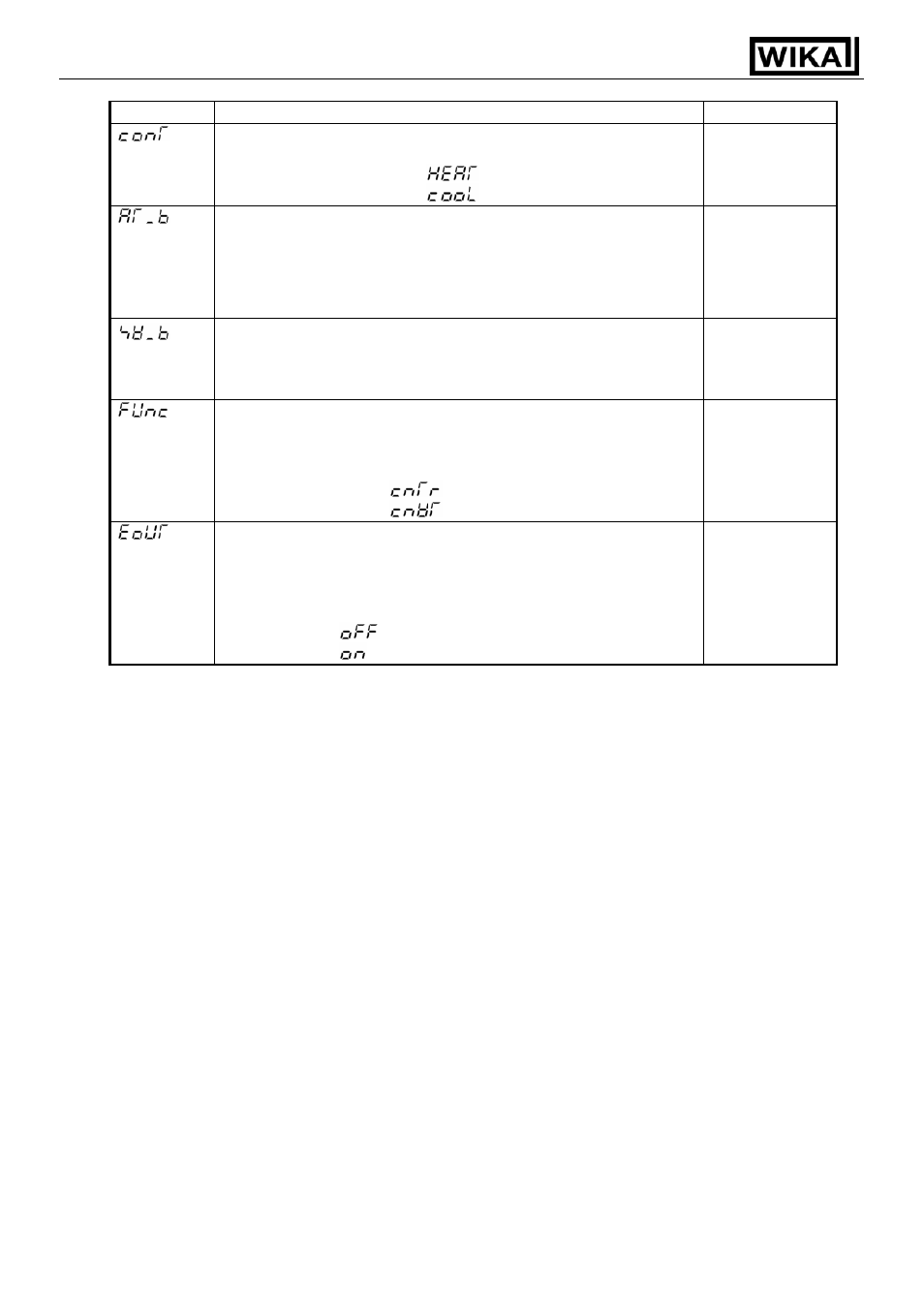

Direct/Reverse selection

•

Selects reverse (heating) or direct (cooling) control action.

•

Reverse (Heating) action :

Direct (Cooling) action

:

Reverse

(Heating) action

AT bias setting

•

Set the PID auto-tuning bias value.

•

Not available when DC voltage or current input is selected

during input type selection, or when action is not PID, either.

•

Setting range: 0 ... 50°C (0 ... 100°F) or

0.0 ... 50.0

°C (0.0 ... 100.0°F)

20°C

SVTC bias setting

•

Control desired value adds SVTC bias value to the value

received by the SVTC command.

•

Available only when the option Digital interface [5] is added.

0

Controller/ Converter function selection

•

Selects controller or converter function.

•

Available only when the control output is analogue current signal

(4...20 mA).

•

Controller function :

Converter function :

Controller

function

Output status selection when input burnout

•

Selects whether the OUT output is turned OFF or not when DC

input is overscale or underscale.

•

Available only for control output analogue current signal

(4 ... 20 mA) with DC inputs.

•

Output OFF :

Output ON :

Output OFF

Sensor correction function

This corrects the input value from the sensor.

When a sensor cannot be set at a location where control is desired, the sensor measuring temperature

may deviate from the temperature in the controlled location. When controlling with multiple controllers,

the accuracy of the sensors or dispersion of load capacity has influence on the control.

Therefore, sometimes the measured temperature (input value) does not concur with the same setting

value. In such case the control can be set at the desired temperature by correcting the input value of

the sensors.

Loop break alarm

The alarm will be activated when the process variable (PV) does not rise as much value as the span or

greater within the time it takes to assess the Loop break alarm after the manipulated variable has

reached 100% or the output high limit value. The alarm will also be activated when the process variable

(PV) does not fall as much value as the span or greater within the time it takes to assess the Loop

break alarm after the manipulated variable has reached 0% or the output low limit value.

When the control action is Direct (Cooling), the alarm acts conversely.