10 eliminating faults – Festo Пневматические линейные приводы SLG User Manual

Page 32

SLG−...

Festo SLG−... 0802d English

32

10

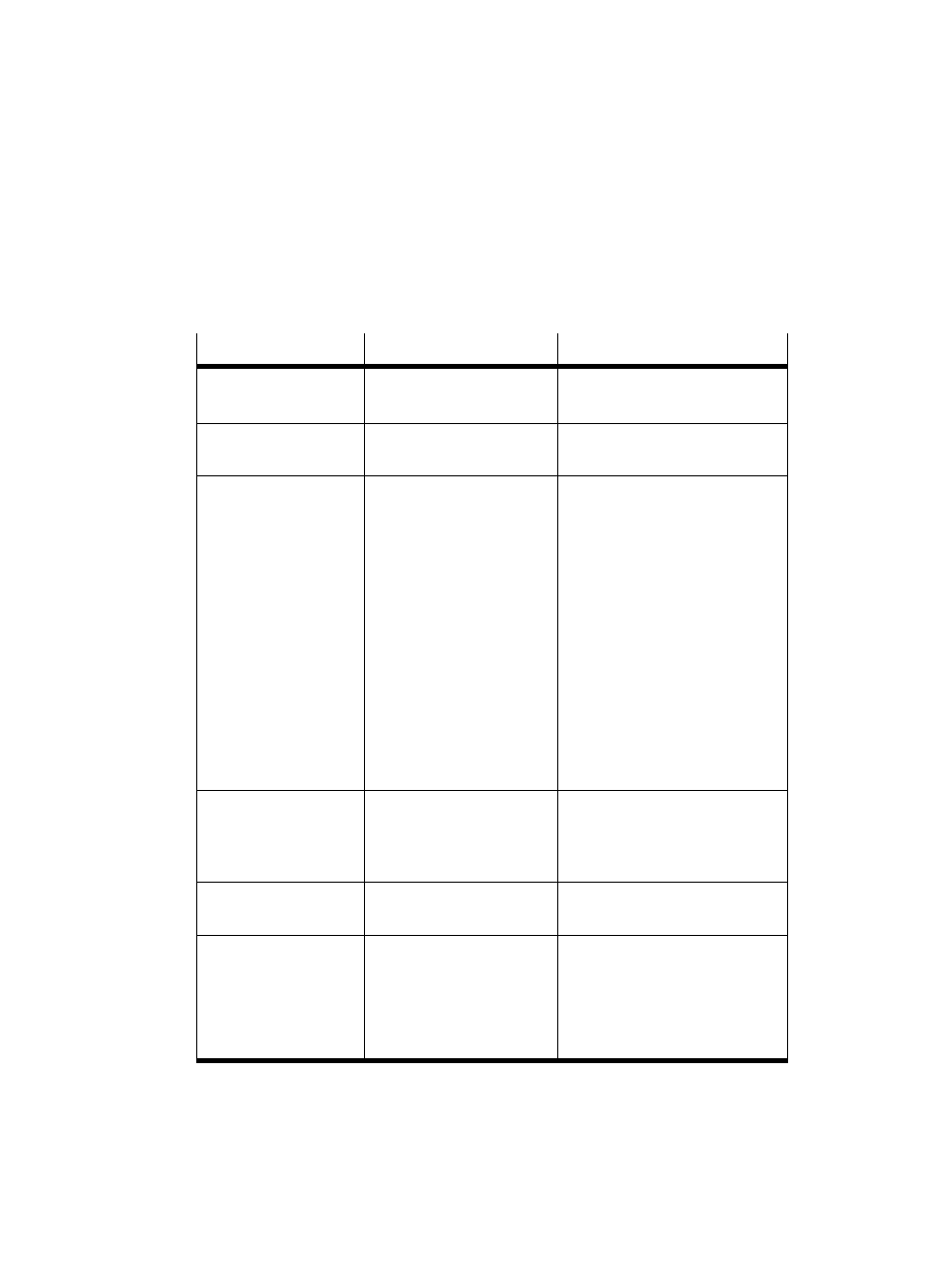

Eliminating faults

Faults

Possible cause

Remedy

Irregular movement of

slide

One−way flow control

valves not fitted correctly

If possible restrict exhaust

Faults in position interĆ

rogation

Ferritic parts near the

proximity switch

Use parts made of non−magnetic

materials

Strong leakage

Ĉ Cylinder fitted distorted

Ĉ Seals worn

Ĉ Seal band pressed/

sucked in

Ĉ Threaded pins not

sealed

Ĉ Fasten cylinder on flat base

Ĉ Replace worn parts

ć yourself with wearing parts

kit

ć send to Festo for repair

Ĉ With pressureless linear drive

move the slide by hand twice

over the complete stroke (if

there are fixed stops push

these into the end position)

Ĉ Avoid low pressure in the pisĆ

ton chamber (e.g. move the

pressureless slide only

slowly)

Ĉ Seal threaded pins in alternaĆ

tive connections

Slide unit does not

reach desired speed

Ĉ Insufficient air volume

Ĉ High wear or counterĆ

acting force

Increase connection cross secĆ

tions.

Switch volume upstream.

Slide jams or has play

Work load evenness not

OK

Observe evenness of 0.1

Slide unit strikes

through the end posiĆ

tion (metal stop)

Ĉ Too much force

Ĉ Cylinder overloaded

Ĉ Cushioning element not

OK

Ĉ Use YSRG

Ĉ Reduce speed

Ĉ Reduce work load

Ĉ Select next size

Ĉ New cushioning element reĆ

quired

Fig. 35