8 care and maintenance, 8care and maintenance – Festo Пневматические линейные приводы SLG User Manual

Page 30

SLG−...

Festo SLG−... 0802d English

30

Applications with vertical fitting:

S

Check whether the loadings of your individual case have been calculated.

Festo offers assistance here with a calculating program (see Accessories).

For achieving higher repetition accuracy:

S

Replace the rubber buffer with shock abĆ

sorbers.

Rubber buffers do not define the end

position exactly.

8

Care and maintenance

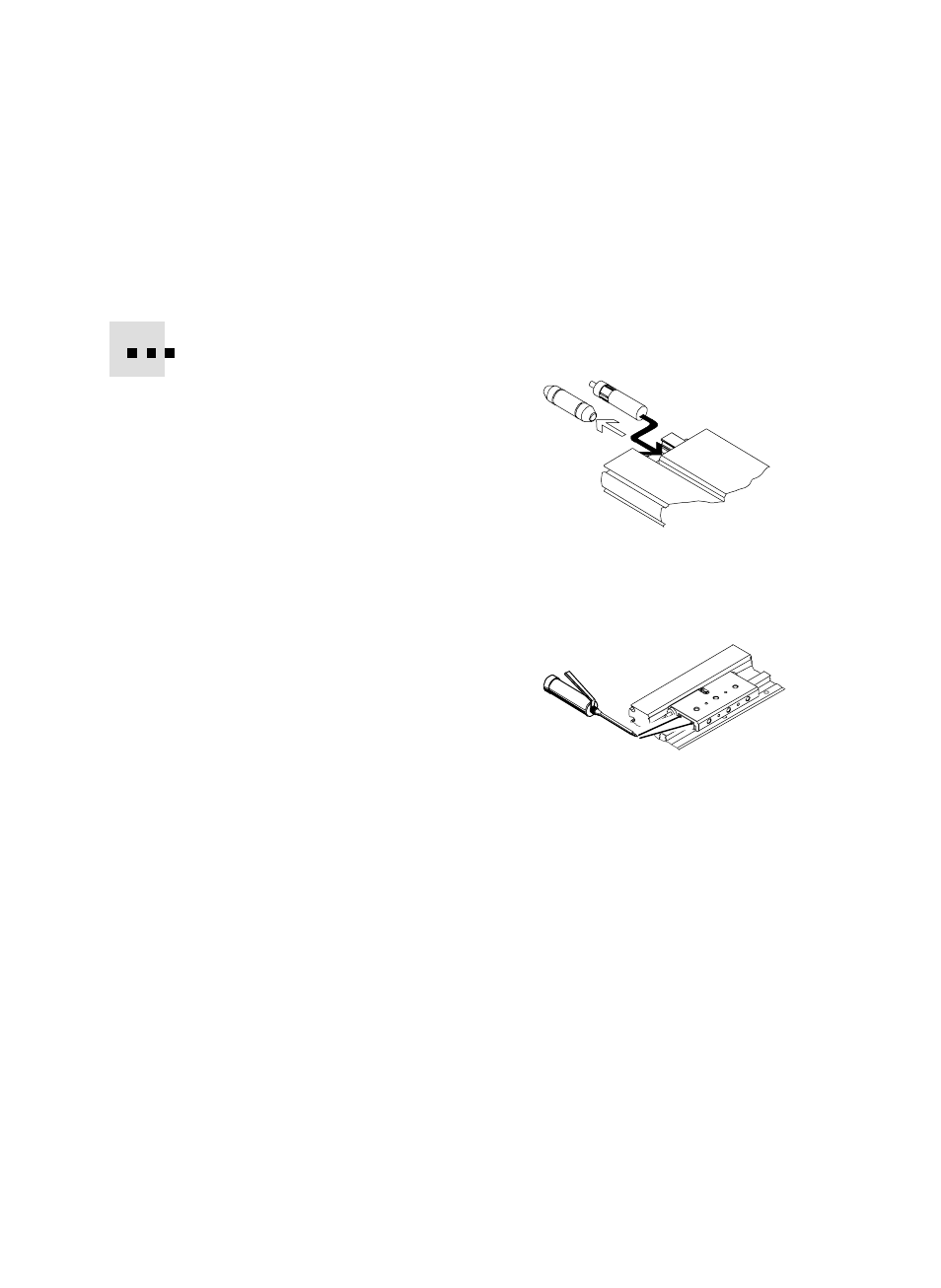

Lubricating the roller bearing guides:

1. Lubricate the SLG−... at the 4 lubrication nipples.

Lubrication intervals: every 5,000 km.

Grease type and gun: see Accessories".

S Note that lubrication must be undertaken more often:

ć in dusty and dirty environments

ć with work strokes of < 50 mm or > 2000 mm

ć at speeds of > 2 m/s

ć in ambient temperatures of > 40 °C.

S Always lubricate the SLG−... at the latest every 3 years.

S Push the slide backwards and forwards during lubrication. Otherwise the

grease cavities will not be filled to an equal extent.

2. Lubricate the guide rail, if it no longer has a layer of grease.

Grease type: see Accessories".

Maintaining the band system:

S

Clean the band system if required with a soft cloth.

Excessive friction or the use of grease−solvent cleaning agents (e.Ăg. soap

suds) will damage the grease layer.

S

Lubricate the surface of the band system if it no longer has a layer of grease.

Grease type: see Accessories".

Fig. 29

Fig. 30