H m l – Comfort-Aire HBH Series 1/2 to 5 Ton User Manual

Page 24

IOM Instructions

HBH/V COMPACT

Heat Controller, Inc.

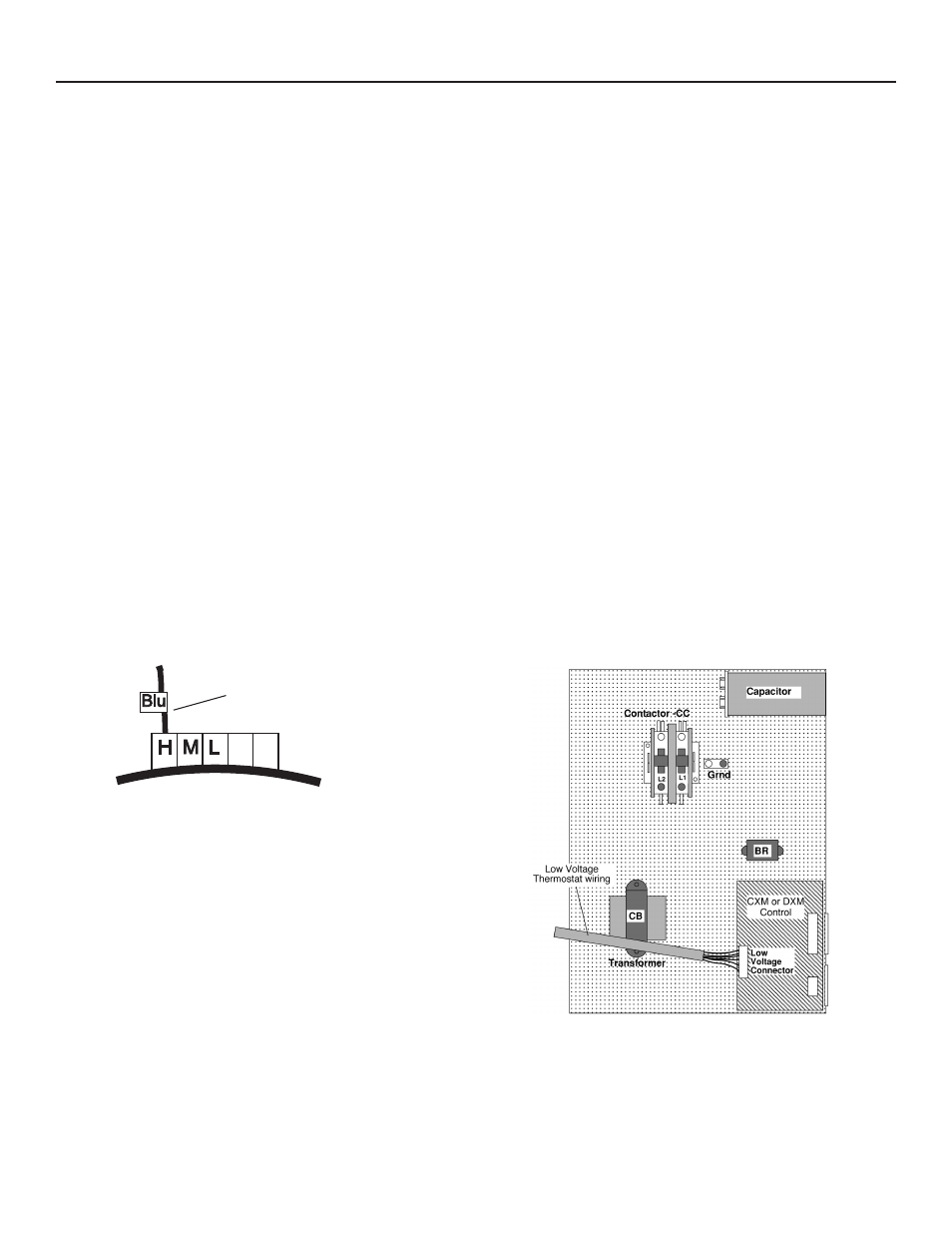

Blower Speed Selection – Units with PSC Motor

PSC (Permanent Split Capacitor) blower fan speed

can be changed by moving the blue wire on the fan

motor terminal block to the desired speed as shown

in Figure 16. Most Heat Controller units are shipped

on the medium speed tap. Consult submittal data or

engineering design guide for specific unit airflow tables.

Typical unit design delivers rated airflow at nominal

static (0.15 in. w.g. [37Pa]) on medium speed and rated

airflow at a higher static (0.4 to 0.5 in. w.g. [100 to 125

Pa]) on high speed for applications where higher static

is required. Low speed will deliver approximately 85%

of rated airflow at 0.10 in. w.g. [25 Pa]. An optional high

static blower is available on some models.

Electrical - Power & Low Voltage Wiring

Special Note for AHRI Testing: To achieve rated

airflow for ARI testing purposes on all PSC products,

it is necessary to change the fan speed to “HI” speed.

When the heat pump has experienced less than 100

operational hours and the coil has not had sufficient time

to be “seasoned”, it is necessary to clean the coil with a

mild surfactant such as Calgon to remove the oils left by

manufacturing processes and enable the condensate to

properly “sheet” off of the coil.

ELECTRICAL - LOW VOLTAGE WIRING

H M L

Azul

Fan Motor

Motor del Ventilador

Conectar el cable azul a:

H para velocidad de ventilador alta

M para velocidad de ventilador media

L para velocidad de ventilador baja

La configuración de fábrica es velocidad

media

Connect the blue wire to:

H for High speed fan

M for Medium speed fan

L for Low speed fan

Medium is factory setting

Fan Motor

Figure 16: PSC Motor Speed Selection

Figure 17: HB Low Voltage Field Wiring

Thermostat Connections

The thermostat should be wired directly to the

CXM board. Figure 17 shows wiring for HB units.

See “Electrical – Thermostat” for specific terminal

connections.

Low Water Temperature Cutout Selection

The CXM control allows the field selection of low water

(or water-antifreeze solution) temperature limit by clipping

jumper JW3, which changes the sensing temperature

associated with thermistor FP1. Note that the FP1

thermistor is located on the refrigerant line between the

coaxial heat exchanger and expansion device (TXV

or cap tube). Therefore, FP1 is sensing refrigerant

temperature, not water temperature, which is a better

indication of how water flow rate/temperature is affecting

the refrigeration circuit.

The factory setting for FP1 is for systems using water

(30°F [-1.1°C] refrigerant temperature). In low water

temperature (extended range) applications with

antifreeze (most ground loops), jumper JW3 should be

clipped as shown in Figure 18 to change the setting to

10°F [-12.2°C] refrigerant temperature, a more suitable

temperature when using an antifreeze solution. All

Heat Controller units operating with entering water

temperatures below 59°F [15°C] must include the

optional water/refrigerant circuit insulation package to

prevent internal condensation.