Caution – Comfort-Aire HBH Series 1/2 to 5 Ton User Manual

Page 13

Heat Controller, Inc.

HBH/V COMPACT

IOM Instructions

Piping Installation

CAUTION! Corrosive system water requires corrosion resis-

tant fittings and hoses, and may require water treatment.

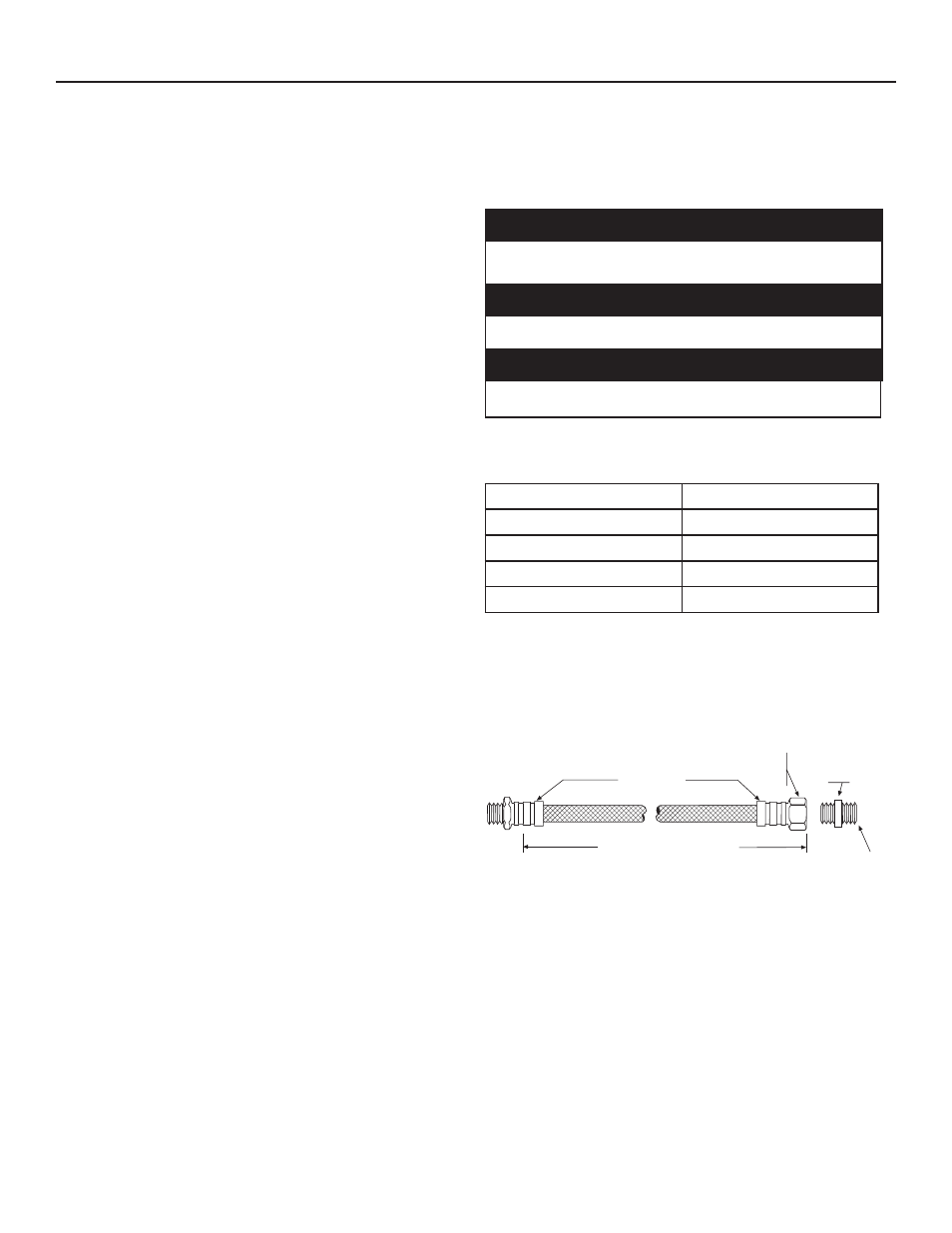

Table 1: Metal Hose Minimum Bend Radii

Hose Diameter

Minimum Bend Radii

1/2" [12.7mm]

2-1/2" [6.4cm]

3/4" [19.1mm]

4" [10.2cm]

1" [25.4mm]

5-1/2" [14cm]

1-1/4" [31.8mm]

6-3/4" [17.1cm]

CAUTION! Do not bend or kink supply lines or hoses.

NOTICE! Do not allow hoses to rest against structural

building components. Compressor vibration may be

transmitted through the hoses to the structure, causing

unnecessary noise complaints.

Figure 11: Supply/Return Hose Kit

CAUTION!

CAUTION!

CAUTION!

Rib Crimped

Length

(2 ft [0.6m] Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

EPT

Reborde Acanalado

Longitud

(Long. Estándar de 2 pies)

Accesorio

Giratorio

de Bronce

Accesorio

de Bronce

MPT

CAUTION! Piping must comply with all applicable codes.

Installation of Supply and Return Piping

Follow these piping guidelines.

1. Install a drain valve at the base of each supply and

return riser to facilitate system flushing.

2. Install shut-off / balancing valves and unions at each

unit to permit unit removal for servicing.

3. Place strainers at the inlet of each system

circulating pump.

4. Select the proper hose length to allow slack between

connection points. Hoses may vary in length by +2%

to -4% under pressure.

5. Refer to Table 1. Do not exceed the minimum bend

radius for the hose selected. Exceeding the minimum

bend radius may cause the hose to collapse, which

reduces water flow rate. Install an angle adapter to

avoid sharp bends in the hose when the radius falls

below the required minimum.

Insulation is not required on loop water piping except

where the piping runs through unheated areas, outside

the building or when the loop water temperature is

below the minimum expected dew point of the pipe

ambient conditions. Insulation is required if loop water

temperature drops below the dew point (insulation is

required for ground loop applications in most climates).

Pipe joint compound is not necessary when Teflon®

thread tape is pre-applied to hose assemblies or when

flared-end connections are used. If pipe joint compound

is preferred, use compound only in small amounts on

the external pipe threads of the fitting adapters. Prevent

sealant from reaching the flared surfaces of the joint.

Note: When anti-freeze is used in the loop, insure that it

is compatible with the Teflon tape or pipe joint compound

that is applied.

Maximum allowable torque for brass fittings is 30 ft-lbs

[41 N-m]. If a torque wrench is not available, tighten

finger-tight plus one quarter turn. Tighten steel fittings

as necessary.

Optional pressure-rated hose assemblies designed

specifically for use with Heat Controller units are available.

Similar hoses can be obtained from alternate suppliers.

Supply and return hoses are fitted with swivel-joint fittings

at one end to prevent kinking during installation.

Refer to Figure 11 for an illustration of a typical supply/

return hose kit. Adapters secure hose assemblies to the

unit and risers. Install hose assemblies properly and

check regularly to avoid system failure and reduced

service life.

A backup wrench is required when tightening water

connections on HB series to prevent water line damage.