Caution – Comfort-Aire HBH Series 1/2 to 5 Ton User Manual

Page 15

Heat Controller, Inc.

HBH/V COMPACT

IOM Instructions

Ground-Loop Heat Pump Applications

Pre-Installation

Prior to installation, locate and mark all existing

underground utilities, piping, etc. Install loops for new

construction before sidewalks, patios, driveways, and other

construction has begun. During construction, accurately

mark all ground loop piping on the plot plan as an aid in

avoiding potential future damage to the installation.

Piping Installation

The typical closed loop ground source system is shown

in Figure 13. All earth loop piping materials should be

limited to polyethylene fusion only for in-ground sections

of the loop. Galvanized or steel fittings should not be

used at any time due to their tendency to corrode. All

plastic to metal threaded fittings should be avoided due

to their potential to leak in earth coupled applications. A

flanged fitting should be substituted. P/T plugs should be

used so that flow can be measured using the pressure

drop of the unit heat exchanger.

Earth loop temperatures can range between 25 and

110°F [-4 to 43°C]. Flow rates between 2.25 and 3 gpm

per ton [2.41 to 3.23 l/m per kW] of cooling capacity is

recommended in these applications.

Test individual horizontal loop circuits before backfilling.

Test vertical U-bends and pond loop assemblies prior to

installation. Pressures of at least 100 psi [689 kPa] should

be used when testing. Do not exceed the pipe pressure

rating. Test entire system when all loops are assembled.

Flushing the Earth Loop

Upon completion of system installation and testing, flush

the system to remove all foreign objects and purge to

remove all air.

Antifreeze

In areas where minimum entering loop temperatures drop

below 40°F [5°C] or where piping will be routed through

areas subject to freezing, antifreeze is required. Alcohols

and glycols are commonly used as antifreeze. Freeze

protection should be maintained to 15°F [9°C] below the

lowest expected entering loop temperature. For example,

if 30°F [-1°C] is the minimum expected entering loop

temperature, the leaving loop temperature would be 25 to

22°F [-4 to -6°C] and freeze protection should be at 15°F

[-10°C]. Calculation is as follows:

30°F - 15°F = 15°F [-1°C - 9°C = -10°C].

All alcohols should be premixed and pumped from

a reservoir outside of the building when possible or

introduced under the water level to prevent fumes.

Calculate the total volume of fluid in the piping system.

Then use the percentage by volume shown in table

2 for the amount of antifreeze needed. Antifreeze

concentration should be checked from a well mixed

sample using a hydrometer to measure specific gravity.

CAUTION! The following instructions represent industry

accepted installation practices for closed loop earth coupled

heat pump systems. Instructions are provided to assist the

contractor in installing trouble free ground loops. These

instructions are recommendations only. State/provincial

and local codes MUST be followed and installation MUST

conform to ALL applicable codes. It is the responsibility of

the installing contractor to determine and comply with ALL

applicable codes and regulations.

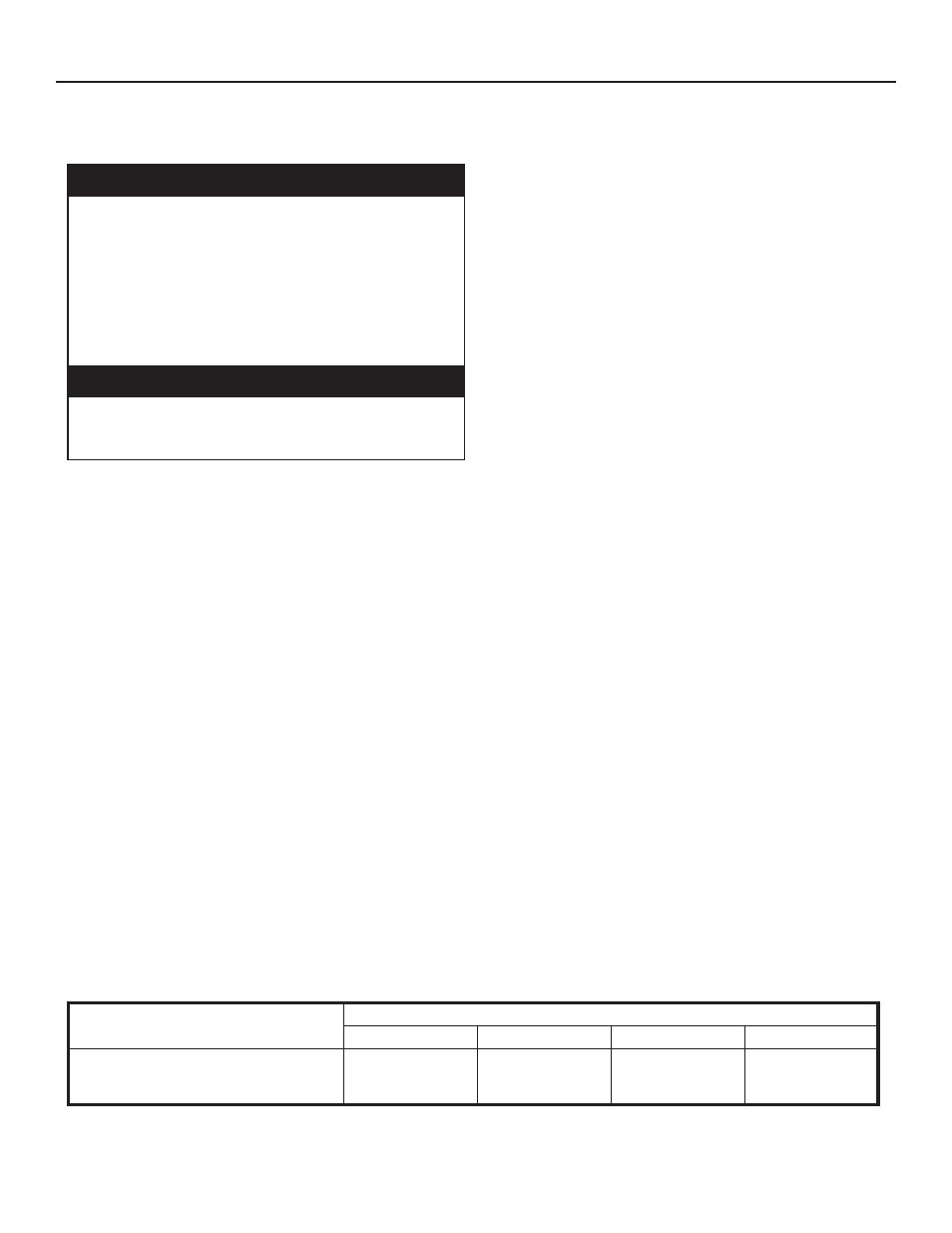

Table 2: Antifreeze Percentages by Volume

Low Water Temperature Cutout Setting - CXM Control

When antifreeze is selected, the FP1 jumper (JW3) should

be clipped to select the low temperature (antifreeze 13°F

[-10.6°C]) set point and avoid nuisance faults (see “Low

Water Temperature Cutout Selection” in this manual). NOTE:

Low water temperature operation requires extended range

equipment.

CAUTION!

CAUTION!

Type

Minimum Temperature for Low Temperature Protection

10°F [-12.2°C]

15°F [-9.4°C]

20°F [-6.7°C]

25°F [-3.9°C]

Methanol

100% USP food grade Propylene Glycol

Ethanol*

25%

38%

29%

21%

25%

25%

16%

22%

20%

10%

15%

14%

* Must not be denatured with any petroleum based product

CAUTION! Ground loop applications require extended range

equipment and optional refrigerant/water circuit insulation.