Digital readout operation, Tubing spring back – Mittler Bros Machine & Tool 2500 User Manual

Page 6

\\Mbserver01\Engineering\Product\Product Documentation\2500 180 HYD Bender\manual\2500 Owners Manual.doc REV.3 11-29-06

- 6 -

3. Place the tubing (which has already been marked with the bend start points) into the

Bender Shoe with the first bend start mark aligned with the START arrow on the

Bender Shoe. Slip the U Saddle over the tubing and the Bender Shoe. Align the holes

up and install the Pin. See diagram at top of Page 8 for details.

CAUTION:

THE PIN MUST BE COMPLETELY THROUGH BOTH SIDES OF THE U

SADDLE! FAILURE TO HAVE PIN COMPLETELY INSTALLED MAY RESULT IN

EQUIPMENT DAMAGE AND / OR PERSONEL INJURY!

4. Align the front edge of the Follow Bar with the START arrow on the Bender Shoe. Be

sure the start mark on the tubing is still lined up with the START arrow as well. Run the

Pressure Roller Adjusting Shaft up to the Follow Bar.

5. PRESSURE ROLLER ADJUSTMENT: Turn hand wheel to move pressure roller into

light contact with follow bar.

NOTE:

If tubing and follow bar begin to rotate toward the shoe, stop and move pressure

roller back from follow bar. Align tubing and follow bar and again move pressure roller

toward shoe until follow bar is making light contact on the tubing at the “start” point.

NOTE:

Follow Bar should be 90-degrees to base plate with tubing nested in cut-out of

follow bar.

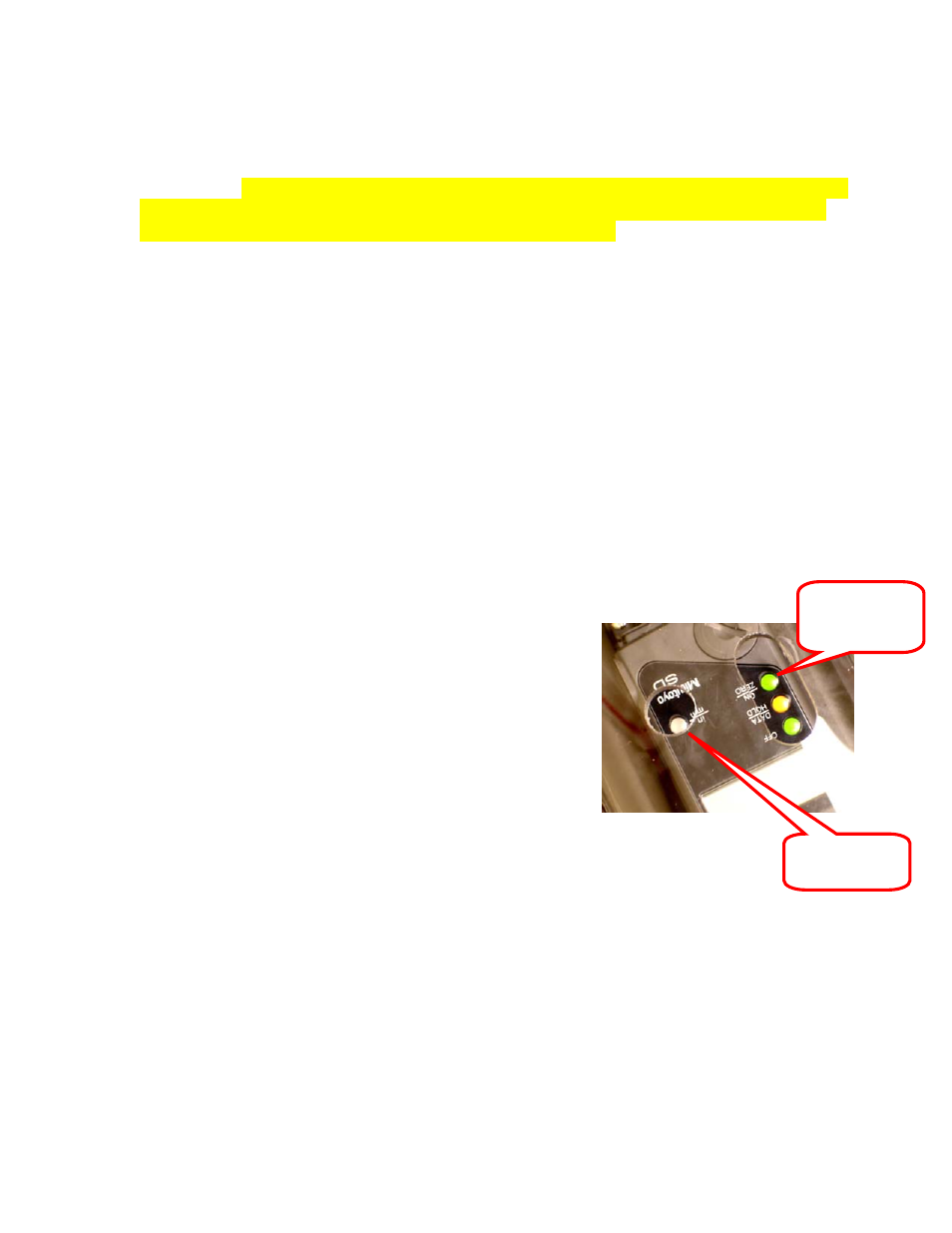

DIGITAL READOUT OPERATION

1. Turn “

ON

” the Digital Readout Assembly.

2. Press the ”in/mm” button so that the “mm” scale is

readable.

NOTE:

Using the “mm” scale will provide

a one degree of bend readout for each “mm” of

indicator travel, for example, a 45mm reading is

equivalent to 45° of bend.

3. Press the “zero” button when you set your Pressure

Roller and are ready to start bending.

TUBING SPRING BACK

The tubing material, wall thickness and amount of bend angle will all influence the amount

of spring-back that must be allowed for.

It is best to test a sample piece of tubing to determine the “spring-back’ before making

your first bend with the type tubing material, wall thickness, and bend angle. Example:

Make a 90-degree bend (digital readout reading 90-degrees) and remove from the shoe.

Position the bent tube on the flat table top of bender with bent angle pointing up and

measure the angle of the bend. If the bend is 87-degrees, then 3-degrees of spring-back

needs to be included, thus bending to 93-degrees will produce a 90-degree finished bend.

PLEASE CONTACT US IF YOU NEED FURTHER ASSISTANCE.

ON / Zero

Button

Inch / MM

Button