Mittler Bros Machine & Tool 550 User Manual

550 shrinker / stretcher, Installation / operation / maintenance

Division of Mittler Corp.

P.O. Box 110 Foristell, Missouri 63348

10 Cooperative Way Wright City, MO 63390

(636) 745-7757

Fax: (636) 745-2874

\\Mbserver01\engineering\Product\Product Documentation\550 Shrinker Stretcher\550 Instructions.doc Rev1 7-13-2006

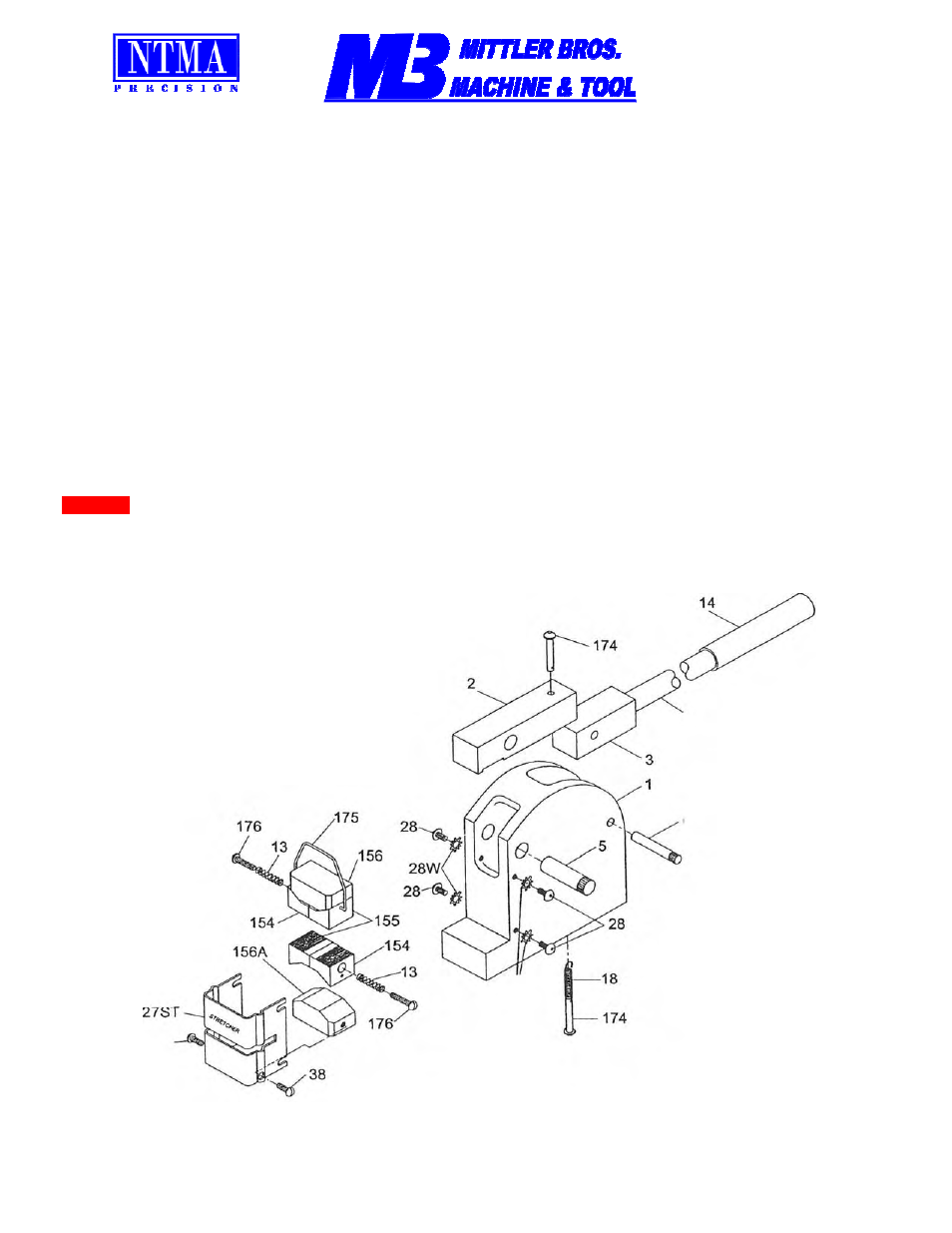

550 Shrinker / Stretcher

Installation / Operation / Maintenance

1.

Secure the tool to the work bench. Two holes are drilled and tapped into the body of the tool to accept two 3/8 - 16 bolts.

It can also be mounted on a vise if portable on-the-job field use is desired. The more rigid you secure it, the easier it is to

use.

2.

Try the tool using a sample piece of metal first to get the "feel" of it. .

3.

When forming any metal, work the leading edge first. This "breaks down" the maximum resistance and permits easy and

accurate working thereafter.

4.

Move the metal back and forth as you apply pressure to the handle until the desired radius is obtained. The control of

these tools lies in the pressure exerted in the handle as the metal is moved back and forth between the jaws.

5.

The jaws of both tools are "toothed" so as to exert a better grip on the metal. These teeth leave slight markings

depending on the hardness of the metal and can quickly be removed with either abrasive cloth or wheel.

CAUTION TIPS:

1.

Notice when you receive your tool that an insert is between the teeth. NEVER press without a separator between jaws:

ALWAYS

insert metal pieces or other material divider between jaws when not in use.

2.

Take handle out of fulcrum slot when not in use to avoid accidental press.