Model icp, 7 reconditioning, 8 mounting – Goulds Pumps ICP - IOM User Manual

Page 27

Installation, Operating and Maintenance Instruction

Model ICP

ICP 100-English

page 18

Revision 00

Article No 24264412

Issue

05/2006

pic 13

Loosen hexagen head bolt (901.41). Remove the

bearing bracket lantern from bearing bracket

(330).

Dismount circlip (932.51). Therefore you need a

snap ring plier acc. to DIN 5256-C.

Bearing

bracket

required snap ring

plier

length i (min.) of

snap ring plier

24

size 94/C 40

200mm

32, 42

size 94/C 85

250mm

48

Größe 94/C 85

300mm

Remove shaft (210) including anti-friction bearing

(320.51 and 320.52) and bearing nut (923.51)

from the bearing bracket (330).

Remove the bearing nut (923.51). The bearing nut

is right hand threaded and self locking. It can be

reused 5 times if it is handled appropriately.

Remove the anti-friction bearing (320.51 and

320.52) from the shaft (210) using a hydraulic

press or a bearing puller.

8.7 Reconditioning

After disassembly all parts must be cleaned and

checked for wear carefully. Worn or damaged parts

must be replaced by new parts (spare parts).

When reassembling the pump it is recommended to

replace all seals.

All PTFE-sealing elements and graphite seal-

ings are intended for being used only once.

In most cases it make sense, if damaged absolutely

necessary, to renew the mechanical seal and the

bearings.

Deposits on the impeller (230), in the volute casing

(102V) or on the casing cover must be removed.

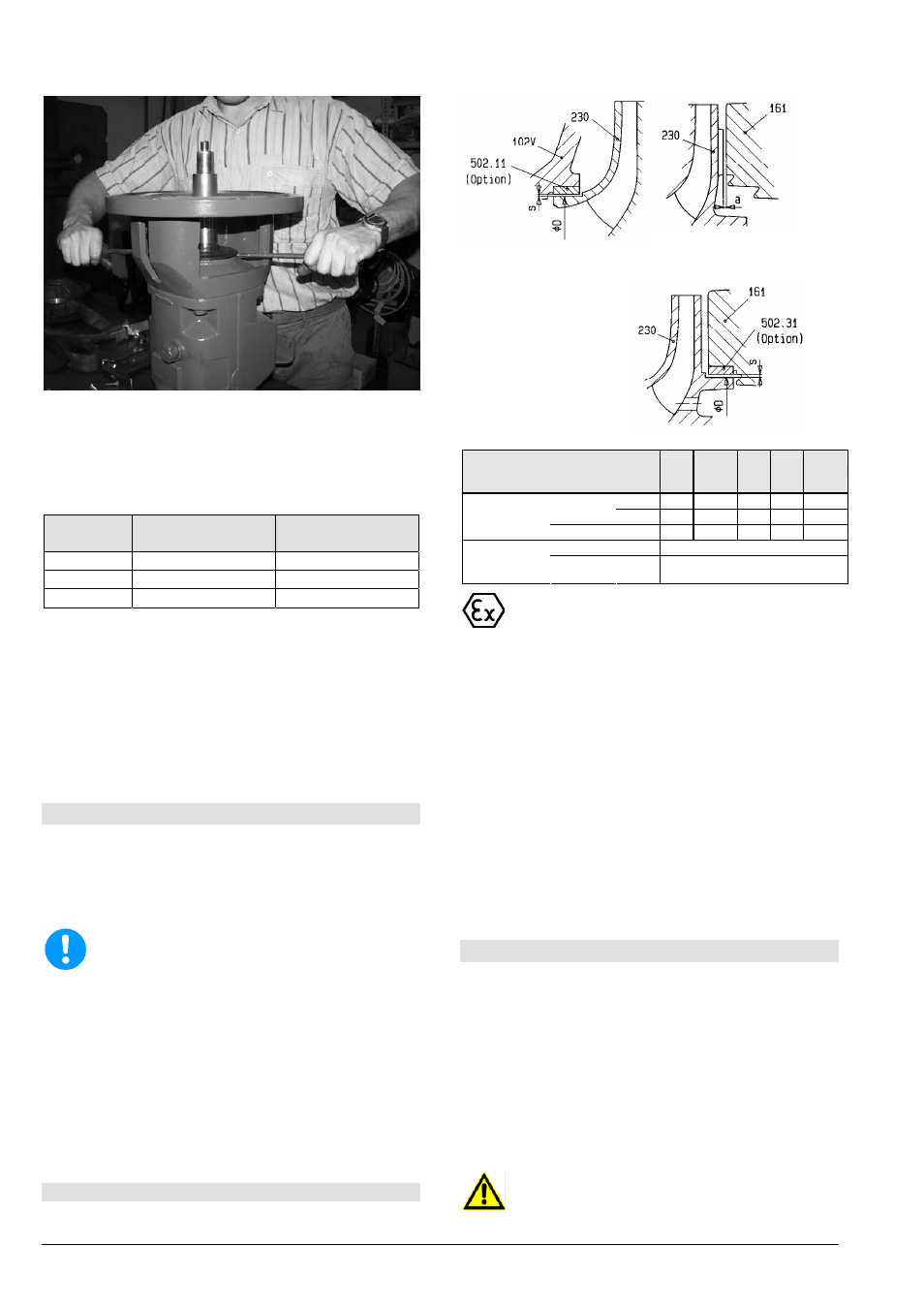

8.7.1 Clearance at impeller

Suction side of impeller

Back vanes of impeller

Drive side of impeller

Only for pump sizes

100-65-315

125-80-315

125-80-400

125-100-315

125-100-400

150-125-315

150-125-400

200-150-315

200-150-400

Nominal diameter D (mm)

60

68

85

100

120

135

155

175

220

min.

0,15 0,17 0,20 0,22

0,25

new

max.

0,19 0,22 0,24 0,27

0,30

Radial

clearance s

(mm)

wear limits

0,78 0,85 0,90 1,05

1,15

new

0,8 - 1,2

Axial

clearance a

(mm)

wear limits

max. 1,7

When the wear limits has been reached or ex-

ceeded, the worn parts must be replaced.

For volute casings (102V) with a wear ring (502.11)

and cover casings (161) with a wear ring (502.31)

there are the following possibilities to restore the cor-

rect clearance:

a) Renew impeller (230) and wear ring. Then the

original measures are restored.

b) A customized wear ring (bored to fit) can be sup-

plied to avoid replacement of the impeller. Please

contact factory for details.

When volute casing (102V) or casing cover (161)

without wear ring must be repaired, a wear ring can

be installed to renew pump performance. Remachin-

ing of the volute casing and /or casing cover is re-

quired. Please contact the factory for details and as-

sistance.

8.8 Mounting

Re-assemble the pumps using the reverse order of

steps as completed for pump disassembly. However

the following observations should be considered:

Pay attention to the utmost cleanliness when re-

assembling the pump.

For tight tolerances, e.g. between shaft sleeve

(433) and shaft (210) or impeller (230) and shaft

(210), as well as thread, use a suitable anti-galling

compound (e.g. Molykote/Never-Seeze), so that

the assembly and the next disassembly will be

easier.

Anti-galling compound must be compatible with

the pumpage.