Model icp, Transport, handling, storage, 1 transport, handling – Goulds Pumps ICP - IOM User Manual

Page 17: Icp 100-english page 8, Pic 2

Installation, Operating and Maintenance Instruction

Model ICP

ICP 100-English

page 8

Revision 00

Article No 24264412

Issue

05/2006

Suction nozzle

Discharge nozzle

Forces in N

Torques in Nm

Forces in N

Torques in Nm

Sizes

∅DN

Fx

Fy

Fz

∑F

Mx

My

Mz

∑M

∅DN

Fx

Fy

Fz

∑F

Mx

My

Mz

∑M

40-25-160

40 1250 1100 1000

1950 1300 900

1050

1900

25

750

700

850

1300 900 600 700

1300

40-25-200

40 1250 1100 1000

1950 1300 900

1050

1900

25

750

700

850

1300 900 600 700

1300

40-25-250

40 1250 1100 1000

1950 1300 900

1050

1900

25

750

700

850

1300 900 600 700

1300

50-32-160

50 1650 1500 1350

2600 1400 1000

1150

2050

32

900

850

1050

1650 1100 750 850

1600

50-32-200

50 1650 1500 1350

2600 1400 1000

1150

2050

32

900

850

1050

1650 1100 750 850

1600

50-32-250

50 1650 1500 1350

2600 1400 1000

1150

2050

32

900

850

1050

1650 1100 750 850

1600

50-32-315

50 1650 1500 1350

2600 1400 1000

1150

2050

32

900

850

1050

1650 1100 750 850

1600

65-40-160

65 2100 1850 1700

3300 1500 1100

1200

2200

40

1100

1000

1250

1950 1300 900 1050

1900

65-40-200

65 2100 1850 1700

3300 1500 1100

1200

2200

40

1100

1000

1250

1950 1300 900 1050

1900

65-40-250

65 2100 1850 1700

3300 1500 1100

1200

2200

40

1100

1000

1250

1950 1300 900 1050

1900

65-40-315

65 2100 1850 1700

3300 1500 1100

1200

2200

40

1100

1000

1250

1950 1300 900 1050

1900

80-50-160

80 2500 2250 2050

3950 1600 1150

1300

2350

50

1500

1350

1650

2600 1400 1000 1150

2050

80-50-200

80 2500 2250 2050

3950 1600 1150

1300

2350

50

1500

1350

1650

2600 1400 1000 1150

2050

80-50-250

80 2500 2250 2050

3950 1600 1150

1300

2350

50

1500

1350

1650

2600 1400 1000 1150

2050

80-50-315

80 2500 2250 2050

3950 1600 1150

1300

2350

50

1500

1350

1650

2600 1400 1000 1150

2050

100-65-160 100 3350 3000 2700

5250 1750 1250

1450

2600

65

1850

1700

2100

3300 1500 1100 1200

2200

100-65-200 100 3350 3000 2700

5250 1750 1250

1450

2600

65

1850

1700

2100

3300 1500 1100 1200

2200

100-65-250 100 3350 3000 2700

5250 1750 1250

1450

2600

65

1850

1700

2100

3300 1500 1100 1200

2200

100-65-315 100 3350 3000 2700

5250 1750 1250

1450

2600

65

1850

1700

2100

3300 1500 1100 1200

2200

125-80-160 125 3950 3550 3200

6200 2100 1500

1900

3050

80

2250

2050

2500

3950 1600 1150 1300

2350

125-80-200 125 3950 3550 3200

6200 2100 1500

1900

3050

80

2250

2050

2500

3950 1600 1150 1300

2350

125-80-250 125 3950 3550 3200

6200 2100 1500

1900

3050

80

2250

2050

2500

3950 1600 1150 1300

2350

125-80-315 125 3950 3550 3200

6200 2100 1500

1900

3050

80

2250

2050

2500

3950 1600 1150 1300

2350

125-80-400 125 3950 3550 3200

6200 2100 1500

1900

3050

80

2250

2050

2500

3950 1600 1150 1300

2350

125-100-200 125 3950 3550 3200

6200 2100 1500

1900

3050

100

3000

2700

3350

5250 1750 1250 1450

2600

125-100-250 125 3950 3550 3200

6200 2100 1500

1900

3050

100

3000

2700

3350

5250 1750 1250 1450

2600

125-100-315 125 3950 3550 3200

6200 2100 1500

1900

3050

100

3000

2700

3350

5250 1750 1250 1450

2600

125-100-400 125 3950 3550 3200

6200 2100 1500

1900

3050

100

3000

2700

3350

5250 1750 1250 1450

2600

150-125-250 150 5000 4500 4050

7850 2500 1750

2050

3650

125

3550

3200

3950

6200 2100 1500 1900

3050

150-125-315 150 5000 4500 4050

7850 2500 1750

2050

3650

125

3550

3200

3950

6200 2100 1500 1900

3050

150-125-400 150 5000 4500 4050

7850 2500 1750

2050

3650

125

3550

3200

3950

6200 2100 1500 1900

3050

200-150-250 200 6700 6000 5400 10450 3250 2300

2650

4800

150

4500

4050

5000

7850 2500 1750 2050

3650

200-150-315 200 6700 6000 5400 10450 3250 2300

2650

4800

150

4500

4050

5000

7850 2500 1750 2050

3650

200-150-400 200 6700 6000 5400 10450 3250 2300

2650

4800

150

4500

4050

5000

7850 2500 1750 2050

3650

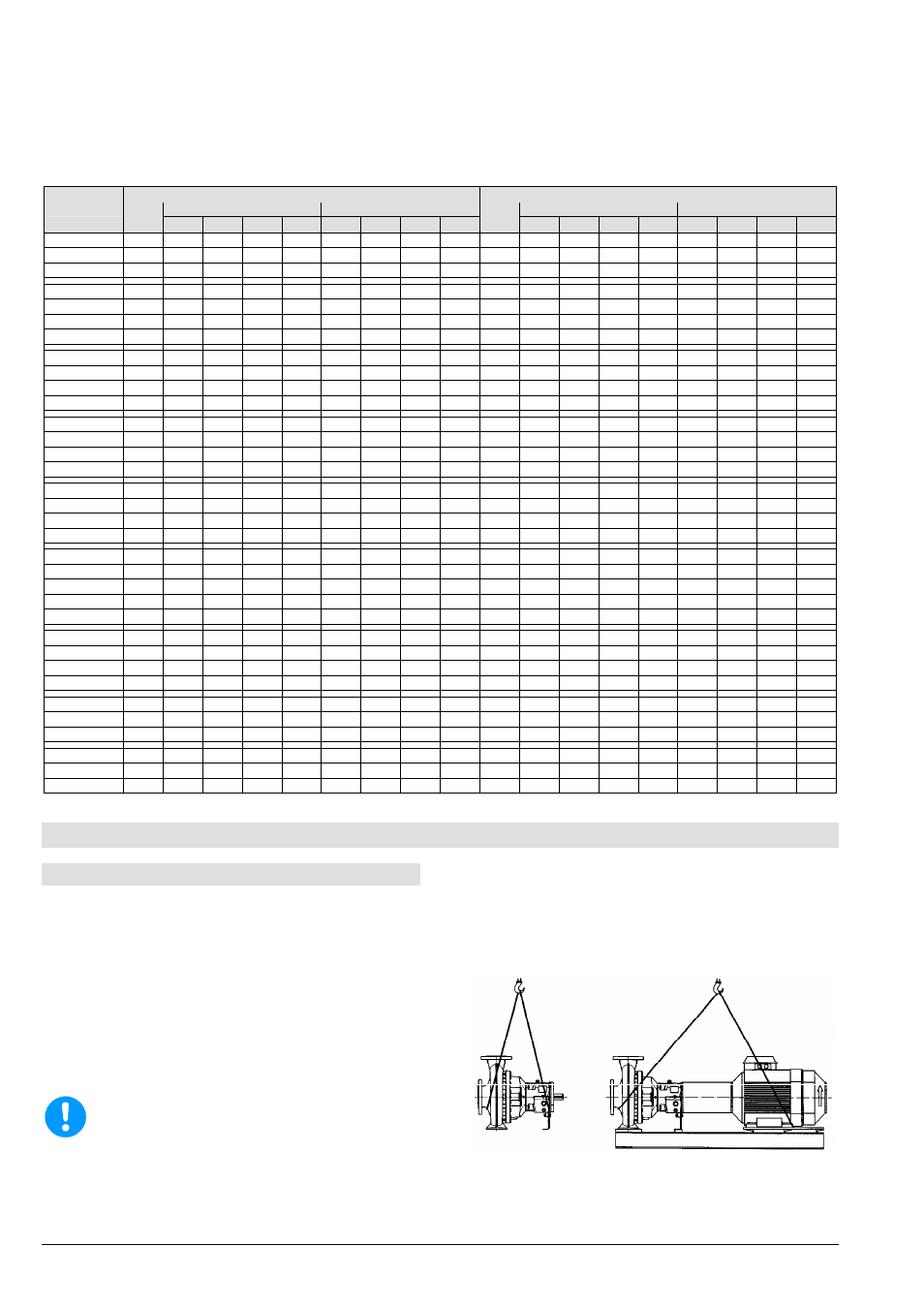

4. Transport, Handling, Storage

4.1 Transport, Handling

Check the pump / pump unit immediately upon

delivery / receipt of despatch for damage or miss-

ing parts.

The pump / pump unit must be transported care-

fully and by competent personnel. Avoid serious

impacts.

Keep the pump/pump unit in the same position in

which it was supplied from the factory. Take note

of the instructions on the packaging.

The suction and discharge side of the pump must

be closed with plugs during transport and storage.

Dispose of all packing materials in accordance

with local regulations.

Lifting devices (e.g. fork-lift truck, crane, crane

device, pulleys, sling ropes, etc.) must be suffi-

ciently strong and must only be used by author-

ized persons. The weight of the pump / pump unit

is given in the data sheet.

The pump / pump unit may only be lifted by solid

points such as the casing, flanges or frame. Pic-

ture 2 shows the correct method of carrying by

crane.

pic 2