Model icp, Servicing, maintenance, 1 general remarks – Goulds Pumps ICP - IOM User Manual

Page 24: 2 mechanical seals, 3 stuffing boxes, 4 lubrication and change of lubricant, 5 coupling

Installation, Operating and Maintenance Instruction

Model ICP

ICP 100-English

page 15

Revision 00

Article No 24264412

Issue

05/2006

b) Drained pumps

Turn shaft at least 1x week (do not switch on be-

cause of dry running).

Replace oil or grease after 2 years.

7. Servicing, Maintenance

7.1 General remarks

Work should only be carried out on the pump or

pump unit when it is not in operation. You must

observe chapter 2.

Maintenance and servicing work must only be

carried out by trained, experienced staff who

are familiar with the contents of these Operat-

ing Instructions, or by the Manufacturer's own

service staff.

7.2 Mechanical seals

Before opening the pump, it is essential that

you note chapter 2 and chapter 8.

If the liquid being handled leaks out at the mechanical

seal, it is damaged and must be replaced.

Replacement of the mech. seal according to accom-

panying "Mounting Instructions for Shaft sealing".

7.3 Stuffing boxes

Stuffing boxes require constant maintenance, see

chapter 6.2 section "Stuffing box". If the leakage rate

can no longer be set correctly, the packing is worn out

and must be replaced in good time (increased wear

on shaft sleeve). Replacement of stuffing boxes acc.

to attached "Mounting Instructions for Shaft Sealing".

Because of the risk of accidents, addition of

packing to pumps during operation or at operat-

ing pressure or temperature is strictly forbidden!

7.4 Lubrication and Change of Lubricant

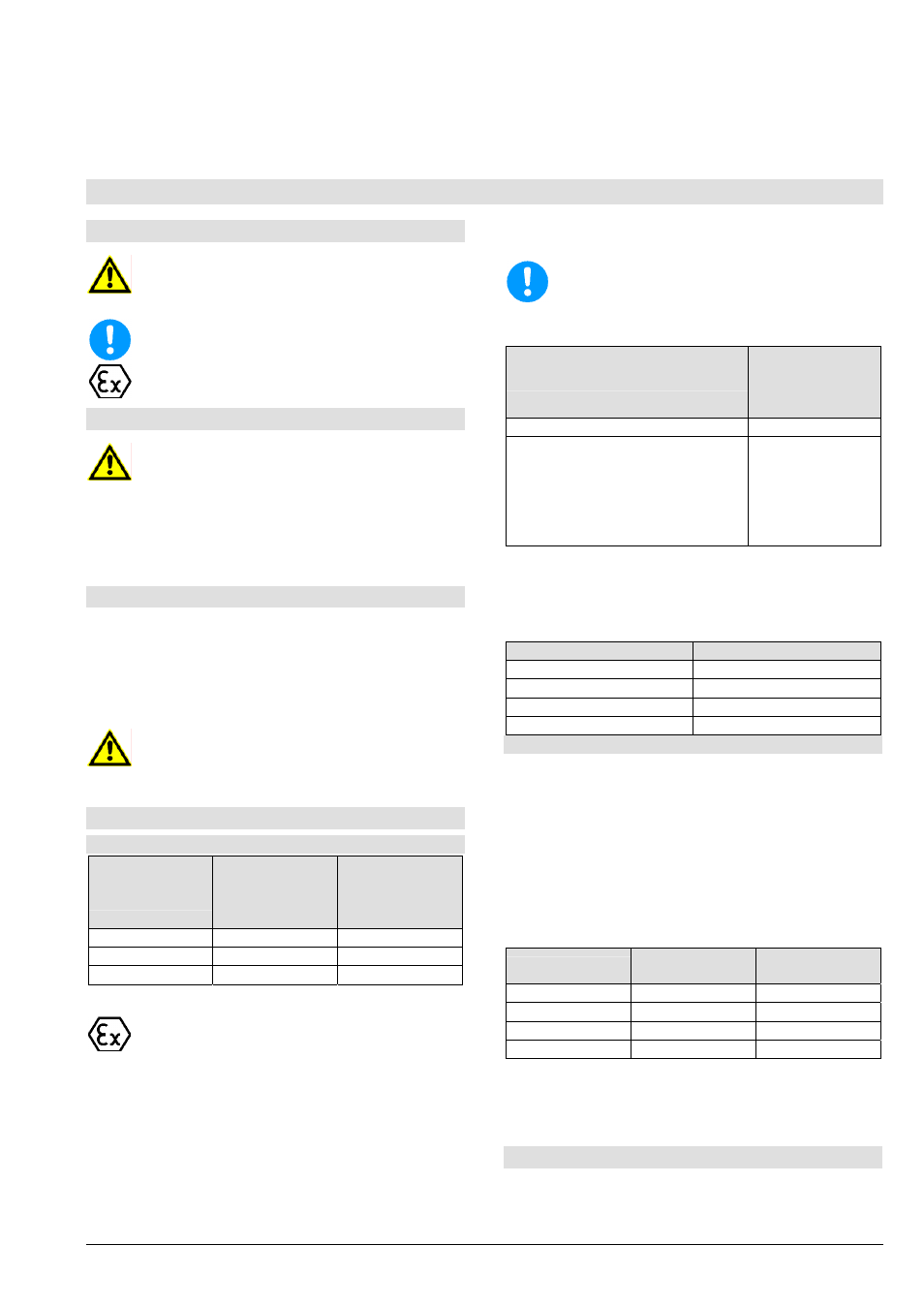

7.4.1 Oil lubrication

Temperature at

bearing

First oil change

after ..... operat-

ing hours

All further oil

changes

after ..... operat-

ing hours

up to 60°C

300

8760 *)

60°C - 80°C

300

4000 *)

80°C - 100°C

200

3000 *)

*) at least 1x year

In plants endangered to explosion the oil

changeing intervals must be kept under any

circumstances!

Oil changing

After the first ....... operating hours, drain oil (oil

drain "GD" with drain plug 903.51) and flush with

fresh oil. Clean oil drain plug and close oil drain

again.

Fill in new oil according to chapter 6.5.

If the pump is left idle for a longer time, the oil

should be changed after two years.

Old oil must be disposed of in accordance with

the valid national environmental regulations.

Oil quality

Name

Lubricating oil

CLP46

DIN 51517 or

HD 20W/20 SAE

Symbol acc. DIN 51502

Kinematic viscosity at 40°C

Flash point (acc. to Cleveland)

Setting point (Pourpoint)

Application temperature *)

46

±4 mm

2

/s

+175°C

-15°C

higher than permit-

ted bearing tem-

perature

*) For ambient temperatures under -10°C an other suitable type of

lubrication oil must be used.

Request required.

Oil quantity

Bearing bracket

Oil quantity in l

24 0,5

32 1,1

42 1,4

48 1,7

7.4.2 Grease lubrication

Re-greasing

Grease lubricated bearings with the possibility of

re-greasing must be re-lubricated all 4000 operat-

ing hours, but at least 1x year. Clean lubricating

nipples (636) first.

Quality of grease lubricant ...

... corresponding to NLGI GRADE 2

Quantity of re-greasing (approx. value)

Bearing bracket

bearing at pump

side

bearing at drive

side

24

9g / 10cm

3

14g / 16cm

3

32

13g / 15cm

3

20g / 22cm

3

42

18g / 20cm

3

33g / 35cm

3

48

23g / 26cm

3

42g / 46cm

3

If the pump is left non-operational for a longer

time, the grease in the bearings should be

changed after 2 years.

7.5 Coupling

Check the clearance in the coupling components

regularly approx. every 1000 operating hours, but at