Model icp, 3 bearings, 4 approximate value for sound pres- sure level – Goulds Pumps ICP - IOM User Manual

Page 16

Installation, Operating and Maintenance Instruction

Model ICP

ICP 100-English

page 7

Revision 00

Article No 24264412

Issue

05/2006

sheet and / or the order confirmation the shaft sealing

type of your pump is shown.

An instruction for the packing of a stuffing box resp.

for the mounting and operation of mech. seals can be

found in the appendix of the particular "Mounting In-

structions of the Shaft Sealing".

In areas endangered to explosion the use of

pumps with packings is forbidden!

Further details about packings and mech.

seals, as well as the therewith connected acci-

dental dangers, you can find in chapter 6.6 and

in chapters 7.2 and 7.3.

3.3 Bearings

The pump shaft is guided by antifriction bearings. In

the data sheet and / or order confirmation you can see,

if your pump is designed for oil lubrication (standard

design) or grease lubrication (special design).

In areas endangered to explosion the use of

pumps with grease lubricated bearings is for-

bidden!

3.3.1 Used bearings

The size of the bearing bracket of your pump is shown

in the data sheet and / or order confirmation.

Bearing type

Bearing bracket

pump side

drive side

24

6307 - C3

3307A - C3

32

6309 - C3

3309A - C3

42

6311 - C3

3311A - C3

48

6313 - C3

3313A - C3

3.3.2 Oil Sump Cooling

On temperatures of the pumped liquid over 160°C an

oil sump cooling is required.

For connection refer to list "Connections" in the annex.

For cooling use pure, non-aggressive water with a

maximum incomming temperature of 30°C.

Cooling water should be hand-warm at discharge.

The pressure in the cooling system must not ex-

ceed max. 6 bar.

Provide control devices for temperature and pres-

sure monitoring.

3.4 Approximate Value for Sound Pres-

sure Level

Sound pressure level L

pA

in dB(A)

Pump alone

Pump + Motor

Nominal

power

P

N

in kW

2950

min

-1

1450

min

-1

975

min

-1

2950

min

-1

1450

min

-1

975

min

-1

0,55 50,5 49,5 49,0 58,0 52,0 51,5

0,75 52,0 51,0 50,5 59,0 54,0 53,0

1,1 54,0 53,0 52,5 60,0 55,5 54,5

1,5 55,5 55,0 54,5 63,5 57,0 56,0

2,2 58,0 57,0 56,5 64,5 59,0 58,5

3,0 59,5 58,5 58,0 68,5 61,0 62,0

4,0 61,0 60,0 59,5 69,0 63,0 63,0

5,5 63,0 62,0 61,5 70,0 65,0 65,0

7,5 64,5 63,5 63,0 70,5 67,0 67,0

11,0 66,5 65,5 65,0 72,0 69,0 68,5

15,0 68,0 67,0 66,5 72,5 70,0 70,5

18,5 69,0 68,5 68,0 73,0 70,5 74,0

22,0 70,5 69,5 69,0 74,5 71,0 74,0

30,0 72,0 71,0 70,5 75,0 72,0 73,0

37,0 73,0 72,0 71,5 76,0 73,5 73,5

45,0 74,0 73,0 72,5 77,0 74,5 73,5

55,0 75,5 74,5 74,0 78,0 75,5 75,0

75,0 77,0 76,0 75,5 80,0 76,5 76,0

90,0 78,0 77,0 -- 80,5 77,5 --

110,0

79,0 78,0 -- 82,5 78,5 --

132,0

80,0 79,0 -- 83,0 79,5 --

160,0

81,0 80,0 -- 83,5 80,5 --

Sound pressure level L

pA

measured in 1 m distance

from pump surface acc. to DIN 45635, part 1 and 24.

Room and foundation influences are not considered.

The tolerance for these values is

±3 dB(A).

Addition with 60 Hz-operation:

Pump alone:

−

Pump with motor: +4 dB(A)

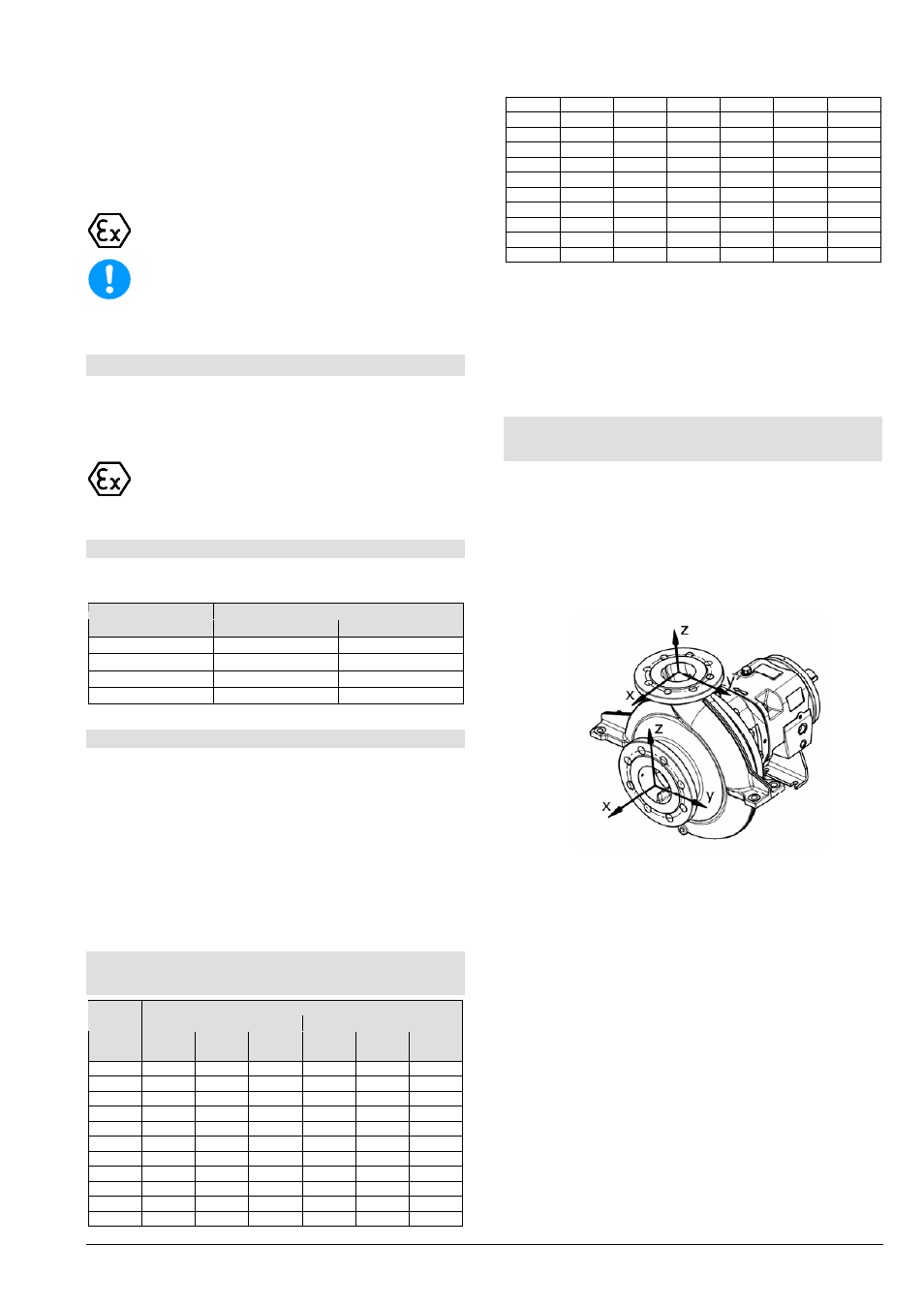

3.5 Permitted Nozzle Loads and Torques

at the Pump Nozzles ...

... following the Europump-Recommendation for

pump acc. to ISO 5199.

The data for forces and torques are only valid for

static piping loads.

The values given in the chart are valid for pump units

with standard-ICP-base frames (ungrouted).

All values for forces and torques refer to standard

materials EN-GJS400-18LT and 1.4408.

pic 1