Model icp, 6 monitoring, 7 shutting down – Goulds Pumps ICP - IOM User Manual

Page 23: 8 storage / longer periods of non- operation

Installation, Operating and Maintenance Instruction

Model ICP

ICP 100-English

page 14

Revision 00

Article No 24264412

Issue

05/2006

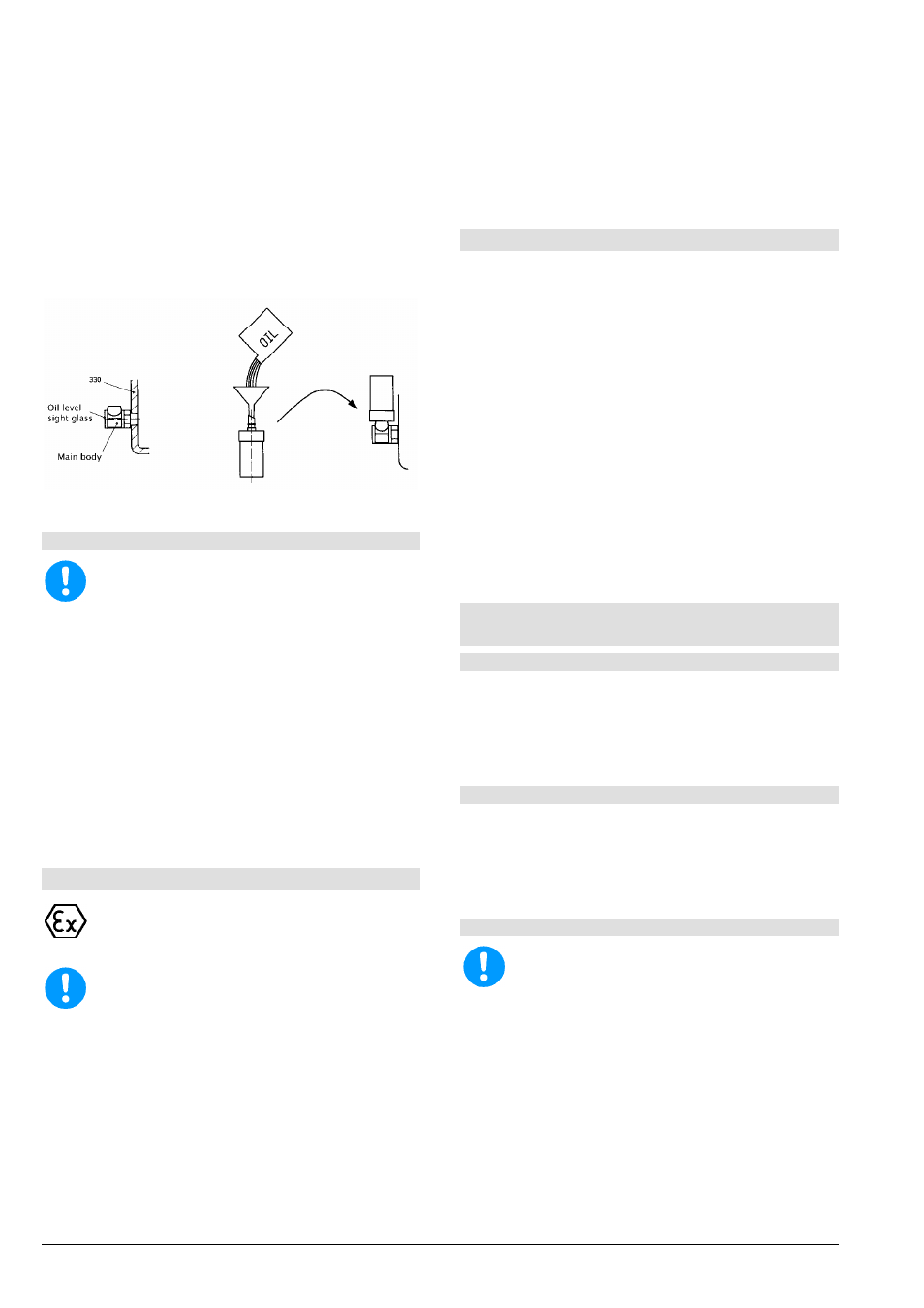

most the middle of the oil level sight glass in the

main body.

Using a funnel, fill the reservoir (picture 8).

Make sure that o-ring is on reservoir spout.

Place thumb over reservoir spout, invert, and

insert the spout into the internal threaded boss on

the main body. Tighten reservoir (picture 8).

Now the oil is flowing from the reservoir into the

bearing chamber.

Repeat filling till the reservoir stays full to 2/3

rd

.

Refill oil as soon as the oil level falls below 1/3

rd

.

pic 8

6.5.2 Grease lubrication

For quality of grease refer to chapter 7.4.2.

For quantity of grease refer to chapter 7.4.2.

The bearings are already filled with lithium based

grease at the factory and are thus ready for use.

The grease provided is suitable for a temperature

range from -30° to +90°C (measured at surface of

bearing bracket).

Re-lubrication via the two grease nipples (636).

Bearing temperature (measured at bearing

bracket) should lie max. 50°C over ambient tem-

perature and must not exceed 90°C, control

weekly at least. On grease lubrication the bearing

temperature can temporarily be higher by 5-10°C

after regreasing, till a possible surplus of grease

in the bearings is cut.

6.6 Monitoring

In areas endangered to explosion it is recom-

mended to monitor the temperature of the bear-

ings and the vibrations of the bearing bracket.

Regular monitoring and maintenance will ex-

tend the life of your pump or pump system.

Check oil level at least once a week and top up if

necessary.

Check pump for leaks at least once a week.

On packing, check quantity of leakage at least

once a week (see chapter 6.2 section "Packing").

Check the regulating and monitoring devices of

any sealing, flushing or cooling systems once a

week to ensure that they function properly. Outgo-

ing cooling water should be handwarm.

With double mechanical seals, monitor pressure

and flow rate in mechanical seal area; check at

least once a week.

Pumps which are exposed to corrosive chemicals

or to wear through abrasion must be inspected

periodically for corrosion or wear and tear. The

first inspection should be carried out after six

months. All further inspection intervals should be

determined on the basis of the state of the pump.

6.7 Shutting down

Close the valve in discharge pipe right before

(max. 30 seconds) switching off the motor. This is

not necessary if there is a spring-loaded check

valve.

Switch off motor (make sure it runs down quietly).

Close the valve on suction side.

Close auxiliary systems. Do not shut down cooling

system until pump has cooled down.

If there is any risk of freezing, empty pump, cool-

ing areas and pipes completely.

If the pump also remains under operating condi-

tions (pressure and temperature) when station-

ary,leave all sealing, flushing and cooling systems

switched on.

The shaft sealing must remain sealed if there is a

risk of air being sucked in (in the event of supply

from vacuum systems or parallel operation with

shared suction pipe).

6.8 Storage / longer periods of non-

operation

6.8.1 Storage of new pumps

If the putting into operation shall happen a longer

period after the delivery, we recommend the following

measures for the storage of the pump:

Store pump at a dry place.

Rotate pump by hand at least once a month.

6.8.2 Measures for longer putting out of operation

Pump remains installed and in ready for operation:

Test runs of 5 min. duration must be made in

regular intervals. The span between the test runs

is depending on the plant. However, it should be

made once a week, at least.

6.8.3 Longer periods of non-operation

After long stationary periods, packings may

have hardened; these must be replaced before

start-up.

When starting up, follow the instructions for

starting up for the first time (see chapter 6)!

a) Filled pumps

Switch stand-by pumps on and immediately off

again once a week. Possibly use as main pump.

If the stand-by pump is at operating pressure and

temperature, leave all sealing, flushing and cool-

ing systems switched on.

Replace oil or grease after 2 years.

Stuffing box must be adjusted to maintain lubrica-

tion of the packing (e.g. do not over tighten).