Goulds Pumps 7200CB - IOM User Manual

Page 97

Maintenance

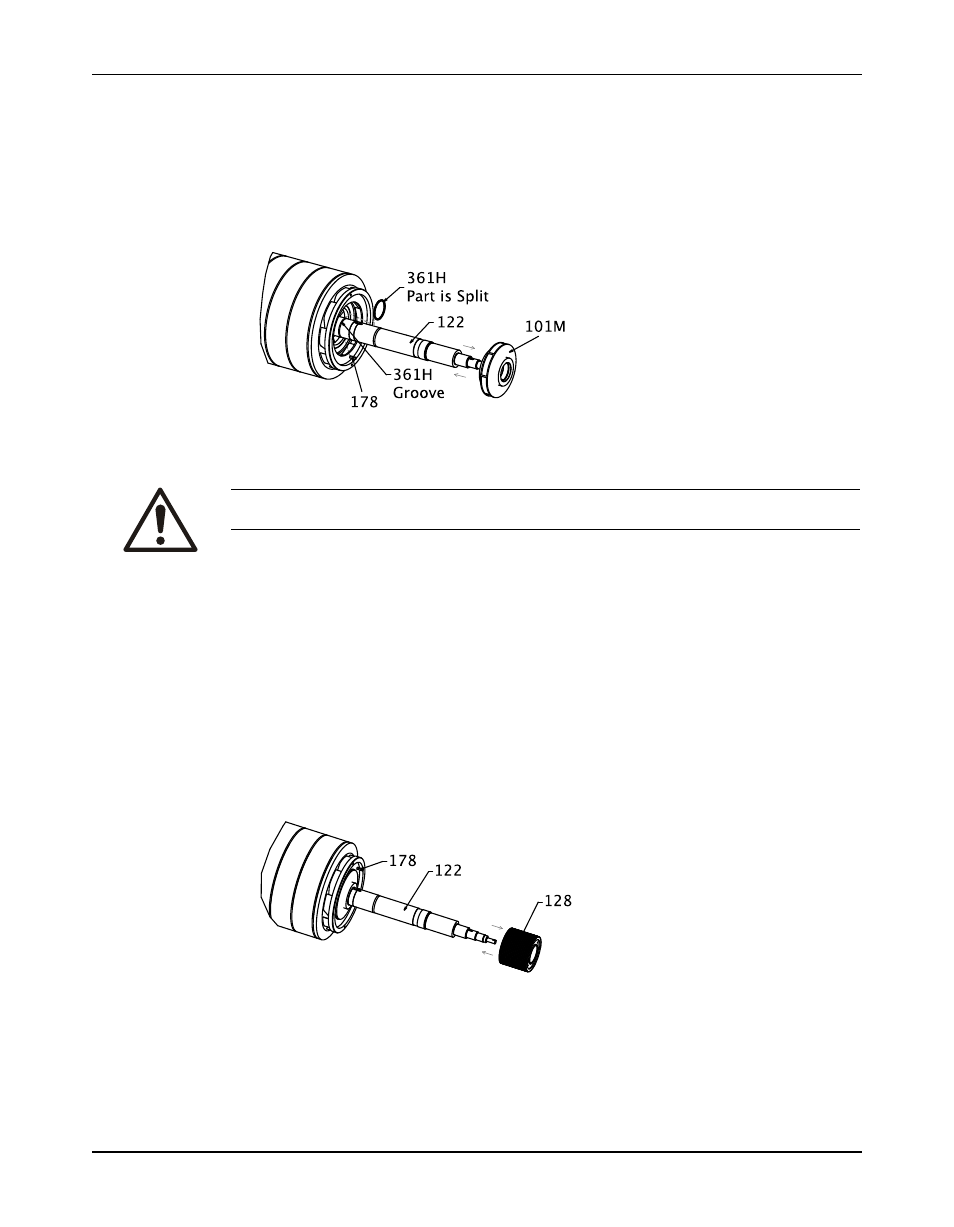

16. Install impeller locating ring (361H) and impeller key (178). Apply high vacuum grease to

both locating ring and key or super glue them in place so they don’t fall out when

assembling the impeller.

CAUTION:

Burn hazard. The impeller will get hot. Wear insulated gloves when handling the impeller.

17. Assemble the last stage impeller (101M) onto the shaft (122) from the thrust end. The

impeller is an interference fit. Use an electric induction heater to heat the impeller to 300°F-

400°F (150°C-200°C). Use puller holes on the impeller hub to assemble onto shaft.

Apply an anti-seize compound to the outer diameter of the impeller rings.

18. Check total travel of rotating assembly. This will remain constant within 0.039 in (1 mm). If

large variation occurs disassemble and diagnose. Something is not seated properly.

19. Install sleeve key (178). Apply high vacuum grease to key or super glue it in place so it

doesn’t fall out when assembling the sleeve.

20. Assemble the balance drum sleeve (128) onto the shaft (122) from the thrust end.

Apply an anti-seize compound to the outer diameter of the balance drum sleeve.

Model 7200CB, API Type BB5 Barrel Multistage / ISO 13709 2nd Edition / API 610 11th Edition Installation, Operation, and

95

Maintenance Manual