Goulds Pumps 7200CB - IOM User Manual

Page 85

Maintenance

NOTICE:

You must have extremely accurate tooling equipment to balance impellers to the ISO G1.0

criteria. Do not attempt to balance impellers to this criteria unless this type of tooling and

equipment is available.

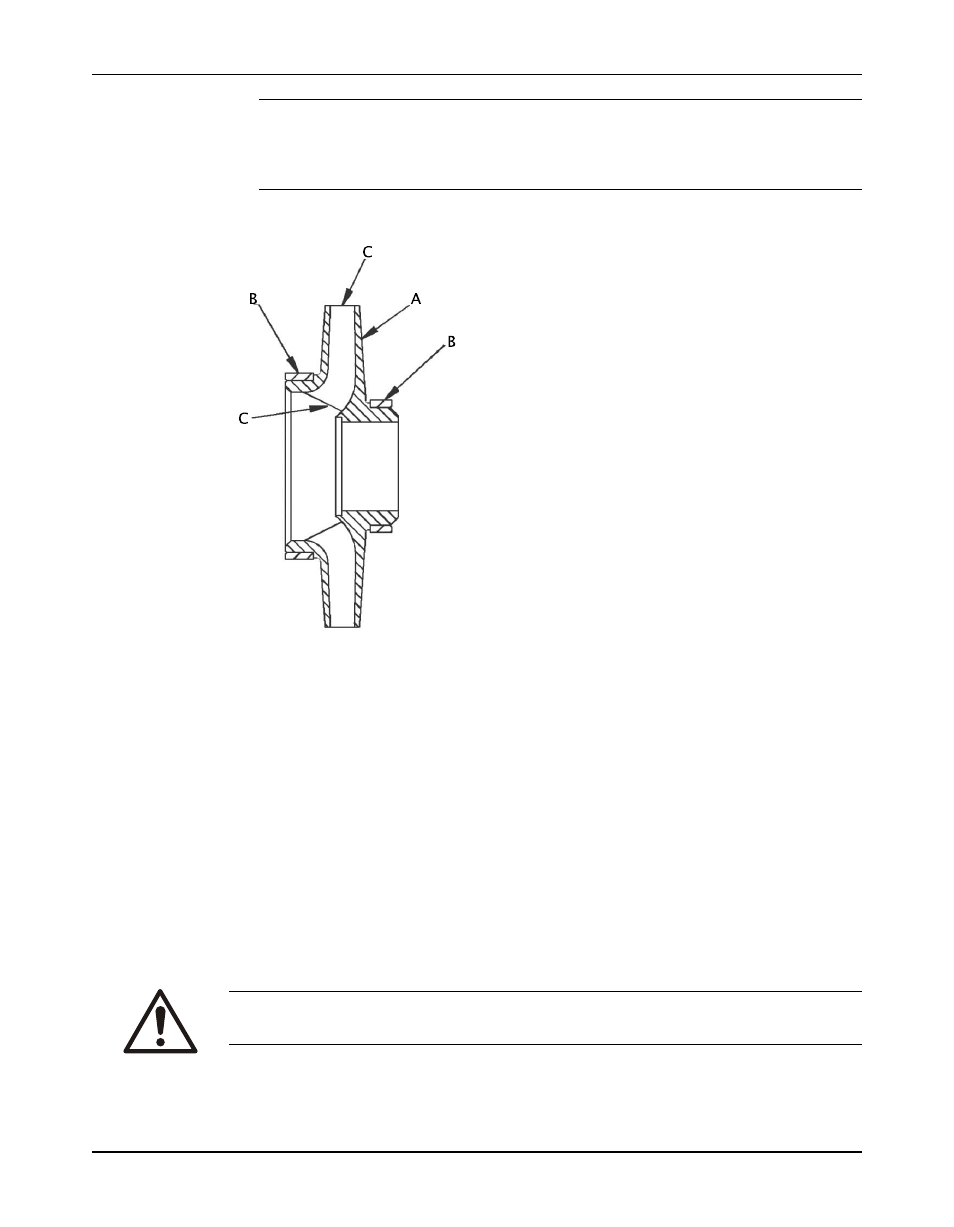

Impeller areas to inspect

A. Shroud

B. Wear ring

C. Vane

Labyrinth seal replacement

Replace the labyrinth-seal O-ring if it has cuts and cracks.

Oil ring replacement

Oil rings must be as round as possible in order to function properly. Replace oil rings if they are

worn, distorted, or damaged beyond reasonable repair.

Cartridge mechanical seal replacement

Cartridge-type mechanical seals should be serviced by the seal manufacturer. Refer to the

instructions from the mechanical seal manufacturer for assistance.

Coupling guard replacement

Repair or replace the coupling guard if you notice corrosion or other defects.

Gaskets, O-rings, and seats replacement

WARNING:

Avoid death or serious injury. Leaking fluid can cause fire and/or burns. Replace any damaged or worn

gaskets/o-rings.

• Replace all gaskets and O-rings at each overhaul and disassembly.

• Inspect the seats. They must be smooth and free of physical defects.

Model 7200CB, API Type BB5 Barrel Multistage / ISO 13709 2nd Edition / API 610 11th Edition Installation, Operation, and

83

Maintenance Manual