Permitted indicator values for alignment checks, Alignment measurement guidelines, Attach the dial indicators for alignment – Goulds Pumps 7200CB - IOM User Manual

Page 24

Installation

Permitted indicator values for alignment checks

NOTICE:

The specified permitted reading values are valid only at operating temperature. For cold

settings, other values are permitted. You must use the correct tolerances. Failure to do so can

result in misalignment and reduced pump reliability.

IMPORTANT

• For electric motors, the motor shaft initial (cold) parallel vertical alignment setting should

be 0.002 to 0.004 in. (0.05 to 0.10 mm) lower than the pump shaft.

• For other drivers such as turbines and engines, follow the driver manufacturer's

recommendations.

When dial indicators are used to check the final alignment, the pump and drive unit are

correctly aligned when these conditions are true:

• The total indicator runout is a maximum of 0.002 in. (0.05 mm) at operating temperature.

• The tolerance of the indicator is 0.0005 in./in. (0.0127 mm/mm) of indicator separation at

operating temperature.

Alignment measurement guidelines

Guideline

Explanation

Rotate the pump coupling half and the driver

This prevents incorrect measurement.

coupling half together so that the indicator rods

have contact with the same points on the driver

coupling half.

Move or shim only the driver in order to make

This prevents strain on the piping installations.

adjustments.

Make sure that the hold-down bolts for the driver

This keeps the driver stationary since movement

feet are tight when you take indicator measure-

causes incorrect measurement.

ments.

Make sure that the hold-down bolts for the driver

This makes it possible to move the driver when you

feet are loose before you make alignment correc-

make alignment corrections.

tions.

Check the alignment again after any mechanical

This corrects any misalignments that an adjustment

adjustments.

may have caused.

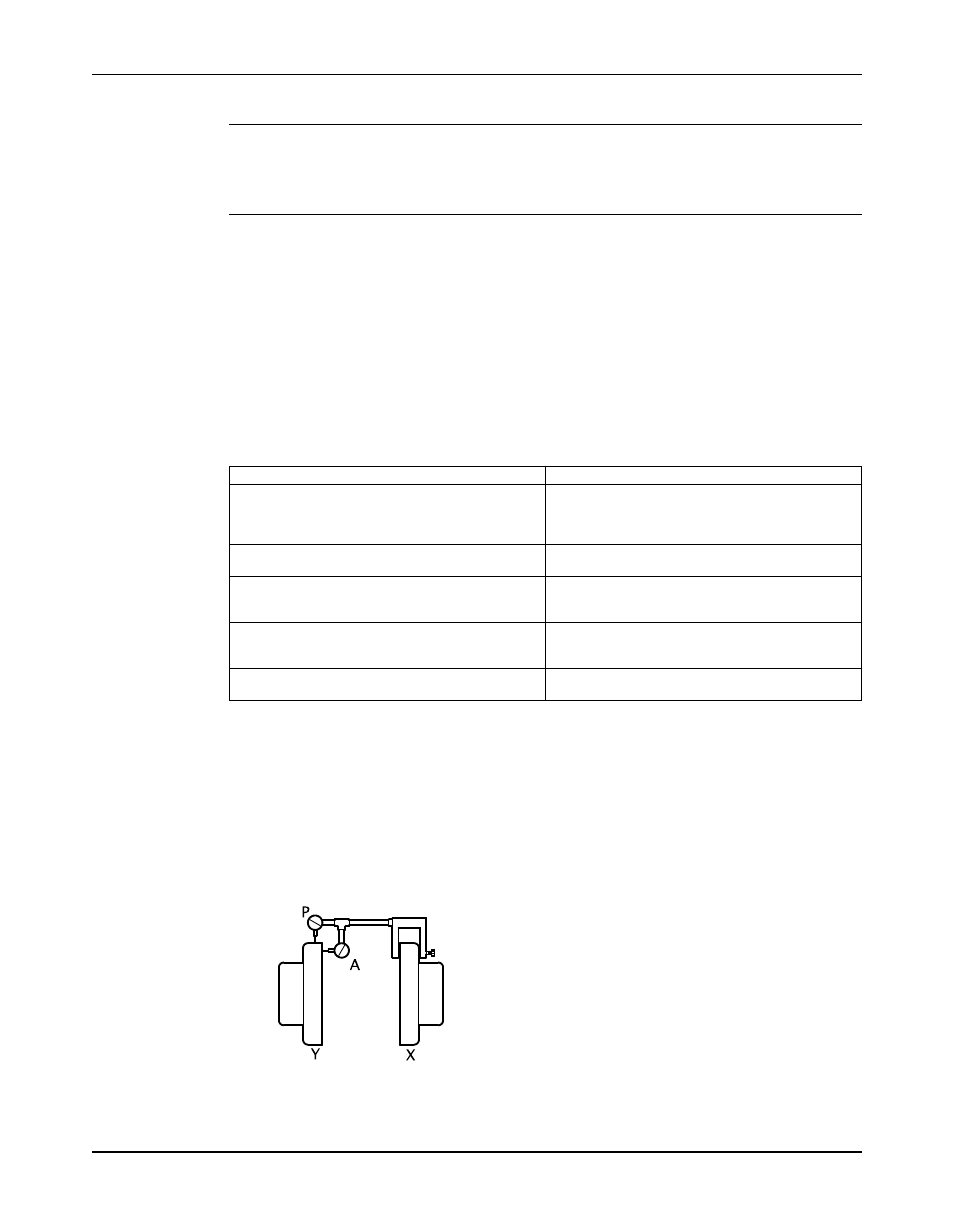

Attach the dial indicators for alignment

You must have two dial indicators in order to complete this procedure.

1. Attach two dial indicators on the pump coupling half (X):

a) Attach one indicator (P) so that the indicator rod comes into contact with the perimeter

of the driver coupling half (Y).

This indicator is used to measure parallel misalignment.

b) Attach the other indicator (A) so that the indicator rod comes into contact with the inner

end of the driver coupling half.

This indicator is used to measure angular misalignment.

22

Model 7200CB, API Type BB5 Barrel Multistage / ISO 13709 2nd Edition / API 610 11th Edition Installation, Operation, and

Maintenance Manual