Assemble the thrust end (ball bearing pumps) – Goulds Pumps 7200CB - IOM User Manual

Page 101

Maintenance

a) Clean the end cover with a solvent.

b) Fit the labyrinth seal (332A) into the bore of the cover (119A). Apply an o-ring lubricant

to the outside diameter of the labyrinth seal o-ring.

c) Tap the seal in with a rubber mallet.

NOTICE:

Make sure that the expulsion port is at the 6 o'clock position and is properly seated.

10. Install the outboard end cover (119A) and the outboard bearing end cover gasket (360A)

onto the shaft. Apply an o-ring lubricant to inside diameter of the labyrinth seal o-ring. Apply

high vacuum grease to gasket.. Tighten the outboard end cover bolts (371C).

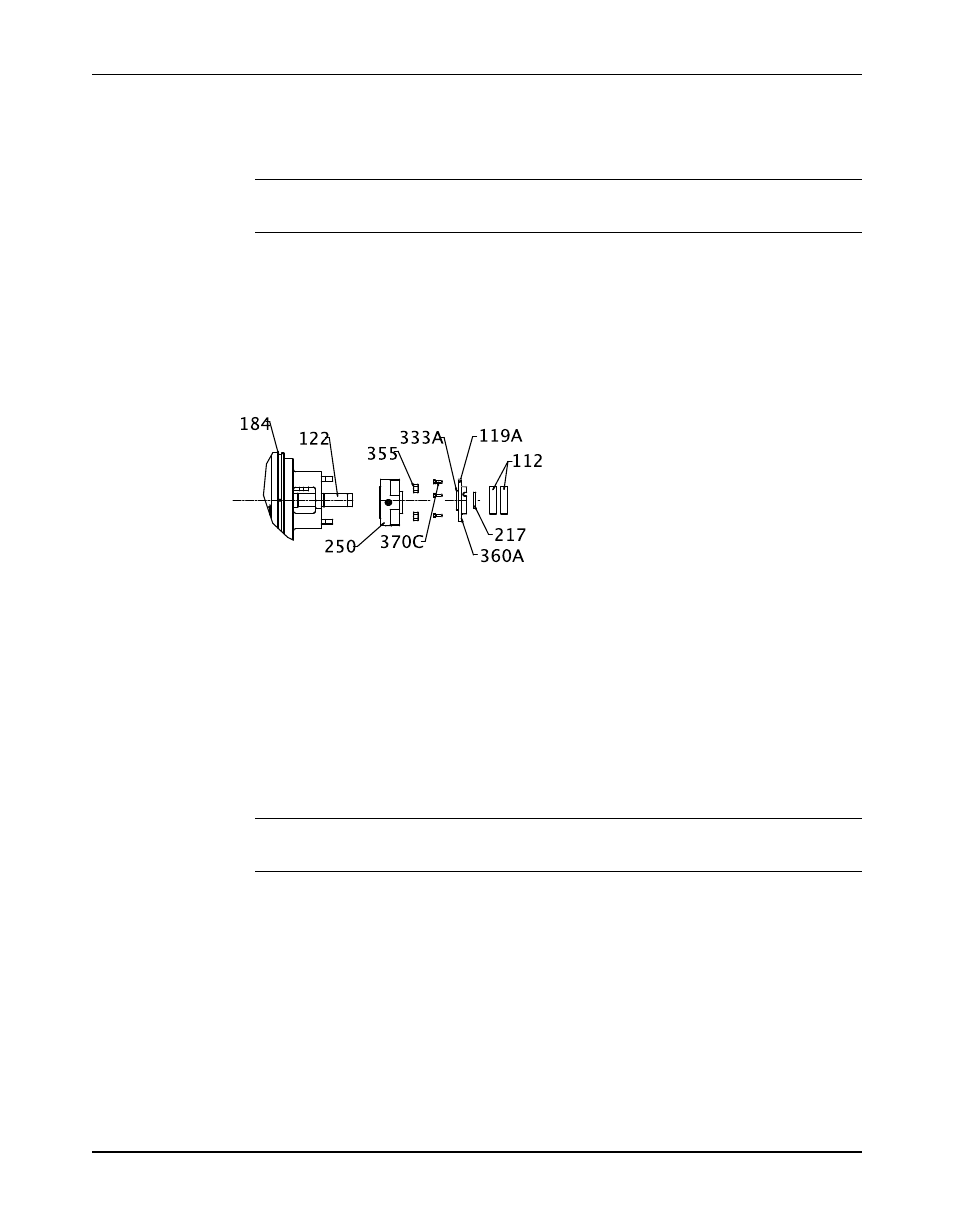

Assemble the thrust end (ball bearing pumps)

1. Install the mechanical seal (250) on the shaft. Apply an o-ring lubricant to the inside

diameter of the seal sleeve o-ring. Torque gland nuts (355) to the values found in the

"Maximum Torque Value for Fasteners" table.

2. Install the inboard labyrinth seal (333A) into the inboard end cover (119A):

a) Clean the end cover with a solvent.

b) Fit the labyrinth seal (333A) into the bore of the cover (119A). Apply an o-ring lubricant

to the outside diameter of the labyrinth seal o-ring.

c) Tap the seal in with a rubber mallet.

NOTICE:

Make sure that the expulsion port is at the 6 o'clock position and is properly seated.

3. Install the inboard end cover (119A) and the inboard bearing end-cover gasket (360A) onto

the shaft. Apply an o-ring lubricant to the inside diameter of the labyrinth seal o-ring. Apply

high vacuum grease to gasket.

4. Final centering of the rotating element cannot be performed without the casing (100). This

step is outlined in section "Final Assembly Steps."

5. Install the bearing spacer (217).

6. Install the bearings (112A) (use flapper wheel to make inside diameter of old bearing a

slight clearance fit) on the shaft.

Model 7200CB, API Type BB5 Barrel Multistage / ISO 13709 2nd Edition / API 610 11th Edition Installation, Operation, and

99

Maintenance Manual